When it comes to industrial boilers, cutting corners isn't just...

Read MoreFAQ

ASME Joint Review FAQ

Explore the most common ASME Joint Review FAQ. From General FAQ, Preparation & Documentation, during the Review, Post-Review & Certification to Common Findings & Fixes.

A Joint Review is a formal audit conducted by ASME and your Authorized Inspection Agency (AIA) to assess your company’s quality control system and ability to fabricate pressure-retaining items in compliance with the ASME Code.

It is required to obtain or renew an ASME Certificate of Authorization and Code Symbol Stamp. The review ensures your company meets the administrative and technical requirements of the ASME Code.

The review team typically includes an ASME Team Leader, a representative from your Authorized Inspection Agency (AIA), and your assigned Authorized Inspector (AI).

A Joint Review is required every three years to maintain your Certificate of Authorization and demonstrate continued compliance with ASME requirements.

Your written Quality Control Manual, implementation of procedures, personnel qualifications, documentation, inspection processes, and demonstration of Code-compliant fabrication are all reviewed.

ASME will issue or renew your Certificate of Authorization, and you’ll be approved to apply the corresponding Code Symbol Stamp to qualifying pressure-retaining items.

Yes. Failure to demonstrate Code compliance, incomplete documentation, or deficiencies in quality system implementation may result in a failed review and withholding of certification.

Most reviews take 1 to 2 days, depending on the size of the organization, number of stamps applied for, and complexity of the demonstration item.

No. Each physical location seeking ASME certification must undergo a separate Joint Review and hold its own Certificate of Authorization.

The review team will issue Findings. You may be required to submit a Corrective Action Plan within a specified time to address the issues before a certificate is issued or renewed.

No. ASME membership is not required. Any organization may apply for a Joint Review as long as it intends to meet Code requirements and submit the appropriate application.

A new review is for first-time applicants seeking ASME certification. A renewal is for organizations maintaining existing certification and requires continued compliance demonstration.

Reviews are typically scheduled 4 to 6 months in advance. Early coordination is recommended to ensure adequate preparation and resource availability.

In most cases, the AIA assigns the AI based on availability and geographic location. Special requests may be considered but are not guaranteed.

Costs include the ASME review fee, travel expenses for the review team, and any charges from your AIA. Some AIs also charge for pre-audit support.

No. An ASME Joint Review focuses specifically on Code compliance and fabrication practices related to pressure-retaining items. ISO audits evaluate broader quality system standards.

No. To legally apply an ASME Code Symbol Stamp, you must be certified through a Joint Review. “Building to Code” without stamping is not equivalent.

No. National Board registration is separate, though closely related. It typically follows the issuance of the ASME Certificate and is often required by jurisdictions.

A new Joint Review is required. ASME Certificates are location-specific and do not transfer to new addresses or buildings.

Yes. You can apply for multiple scopes at once, but each stamp must be covered by your quality program and demonstrated during the review.

No. ASME requires Joint Reviews to be conducted in person at the physical facility applying for certification. The review team must verify implementation on-site.

No. You must demonstrate that your systems are in place and that you can fabricate to Code. You must have either ongoing Code work or a mock-up ready for demonstration

Only if your quality system fully controls the subcontracted processes and you retain Code responsibility. ASME expects some in-house capability to verify compliance.

The Authorized Inspector (AI) represents the AIA. They verify that your quality system supports Code requirements and that AI involvement is properly documented.

All required documents and discussion during the review must be in English or supported by a competent translator. Miscommunication can impact outcomes.

CA Connect is ASME’s portal for submitting applications, uploading documents, managing review schedules, and receiving certification updates.

No, but you must demonstrate your ability to fabricate a Code-compliant item using your quality system during the review.

Key personnel — especially the quality manager — must be present. If unavailable, the review may be postponed or result in findings for lack of system ownership.

Yes. ASME provides a formal appeal process if you believe a review was unfair or incorrect. Supporting documentation must be submitted.

The applicant company, ASME, and the AIA all receive official copies. Review findings and final certification decisions are recorded through CA Connect.

The manual must describe your company’s procedures for material control, welding, inspection, testing, documentation, calibration, record retention, and any specific ASME Code requirements relevant to your scope.

Yes. The manual must reference the applicable ASME sections (e.g., Section I, Section VIII) and clearly outline how your procedures meet those Code requirements.

Your most current QC Manual, all referenced procedures, sample traveler package, weld procedure qualifications (WPS/PQR), welder performance qualifications (WPQs), calibration records, material traceability documents, and past NCRs (if any).

A traveler is a controlled document that tracks each step of fabrication, inspection, and testing for a Code item. It demonstrates real-time application of your QC procedures.

No. Your QC Manual must be customized to reflect your actual processes and operations. ASME expects the manual to match your facility’s practices.

You must fabricate or partially fabricate a Code-compliant sample item during the Joint Review that allows demonstration of welding, inspection, NDE, documentation, and AI involvement.

es, as long as it includes all key processes — such as welding, inspection, pressure testing, and recordkeeping. The item must clearly show your ability to follow the Code.

Welders must be qualified in accordance with ASME Section IX. Their WPQs must be documented, current, and within the essential variable limits of the WPS used during the demo.

Yes. All inspection and test equipment must be calibrated using traceable standards, and records must show due dates, serial numbers, and calibration sources.

Only if they are part of your approved QC system. Subcontracted activities must be controlled through documented procedures, and their qualifications must be available during the review.

It should clearly document each fabrication and inspection step, including weld joint locations, WPS assignments, hold points, material traceability, and inspector sign-offs.

Yes. ASME allows digital documentation, provided it is secure, traceable, and accessible during the Joint Review. Your QC Manual must define how digital records are managed.

Common issues include incomplete traveler records, missing material traceability, expired calibration logs, unsigned weld maps, and outdated procedures.

You must show records for QC inspectors, welders, and anyone involved in Code-related activities — including training logs, qualification tests, and certifications.

Not required, but if available, completed jobs can support your quality system credibility. Focus is placed on the sample job fabricated during the review.

Yes. You must demonstrate how nonconformances are identified, documented, reviewed, and closed with corrective action. An example NCR is highly recommended.

Through a material receiving and inspection process, with mill test reports (MTRs), heat numbers, and traceability records linked to specific job travelers.

Welder qualifications must be valid under your company’s WPS and documentation system. If transferred, they must be reviewed and accepted under your QC Manual.

Only if you have ownership or formal rights to them. Most companies develop and qualify their own PQRs to maintain traceability and control.

Yes. All activities governed by the Code — such as welding, inspection, NDE, calibration, and documentation — must be supported by written, controlled procedures.

At least one welder must demonstrate Code welding as part of the sample job. That welder must be qualified under Section IX.

Yes. If tack welds remain in place or affect final weld quality, the tack welder must be qualified to the same standards as production welders.

The level depends on your stamp scope. At minimum, you must show how NDE is performed, reviewed, and documented per the applicable Code section.

Yes, if they are approved under your QC system and meet personnel qualification standards like SNT-TC-1A. You must review and accept their procedures and reports.

The log must show each welder has used the process at least once every six months. Dates, processes, and job numbers must be clearly listed.

No, as long as their qualifications remain within the essential variable limits of the WPS and they have maintained continuity.

Provide documentation showing your review and acceptance of the subcontractor’s qualifications, work scope, and inspection results. Include them in your QC Manual if applicable.

Tools must be listed in a calibration log, assigned a unique ID, have current calibration dates, and traceability to a national standard (like NIST).

No. You must perform live steps during the review — including welding, inspection, and documentation — using a real-time demonstration item.

Yes. While you may combine similar systems, your QC Manual must address each stamp’s specific requirements and how your program satisfies them.

The review team typically starts with an opening meeting to introduce participants, review the agenda, confirm the QC scope, and discuss the sample item to be demonstrated.

The Team Leader oversees the review process, ensures ASME expectations are met, evaluates your quality system, and makes final certification recommendations to ASME.

The AI confirms that your system properly integrates Authorized Inspection and that inspection points, documentation, and communication channels are clearly defined and followed.

They may ask about your QC procedures, material control, weld tracking, documentation, and how your personnel apply Code requirements in daily work. Expect technical and procedural questions.

Yes. A walkthrough is typically included to evaluate shop organization, equipment condition, material control, welder IDs, and general Code-related practices.

Mistakes can happen. The key is showing that your system catches and corrects them — through proper NCRs, rework procedures, and inspector involvement.

Yes, normal operations can continue, but the demonstration item and review discussions must remain the focus. Disruptions should be minimized where possible.

Yes. They expect to witness welding, inspection, or testing during the demonstration to verify practical implementation of your QC procedures.

It depends on the complexity, but it should show all major aspects of your Code scope — typically including welding, inspection, documentation, and AI engagement within a few hours.

Expect questions during and after the demo. Reviewers may pause to clarify observations, ask how decisions are made, or verify alignment with your QC Manual.

Missing documents often result in a finding. The review team may allow limited time to retrieve the item, but unresolved gaps can prevent certification.

Yes. The Authorized Inspector must be present throughout the Joint Review, especially during the demo and discussion of AI involvement and hold points.

Hold points are stages in fabrication where work stops until inspection is performed. The review team checks if they are defined, documented, and followed consistently.

Yes. They may request supporting procedures for welding, inspection, handling NCRs, subcontractor control, or calibration — especially if referenced in the manual.

Yes. Each relevant person — welders, inspectors, quality managers — should be present and engaged. The review team will want to speak directly to those implementing the system.

Common issues include lack of traceability, missing inspector sign-offs, improper material certification handling, or unclear delegation of quality responsibilities.

Absolutely. The review focuses heavily on whether your documented system is being followed in practice — not just that it exists on paper.

Yes, and it’s encouraged. Documenting reviewer feedback helps you address potential findings quickly and shows attentiveness to the process.

Both. Findings are typically discussed at the closing meeting, then documented in the official Joint Review report available via CA Connect.

This won’t automatically fail the review. The focus is on how your team responds — documents the issue, applies procedures, and demonstrates Code-compliant corrective actions.

The review team will summarize their observations, present any findings or concerns, answer final questions, and explain the next steps in the certification process.

Absolutely. If something is unclear or seems incorrect, it’s appropriate to ask for clarification. The review is collaborative, not adversarial.

Yes. Reviewers will check that welders performing demo work are qualified under Section IX and that their continuity and ID tracking is current.

Only partially. You may prep some components, but reviewers expect to observe live fabrication steps during the review — not just show-and-tell.

Yes. If applying for more than one stamp (e.g., U and UM), the demonstration item should incorporate elements relevant to each stamp’s scope.

If the document is truly required and not part of your prepared package, it may result in a finding. You may be allowed to clarify or supplement during the review if time permits.

No. Your internal staff must demonstrate ownership of the QC system. Third parties may be present but should not speak on your behalf.

Out-of-date calibration records are a common finding. Affected tools must be removed from service, and the team may question system control if multiple lapses are found.

Only under serious, unexpected circumstances — like equipment failure or personnel emergencies. Otherwise, postponement may impact your application status.

While the final report is issued later, the review team usually gives a clear indication during the closing meeting whether the outcome is positive or if follow-up is needed.

Certificates are typically issued within 2 to 4 weeks after the review, once ASME processes the final report and confirms all findings have been resolved.

Certificates are issued digitally through ASME’s CA Connect portal. A physical copy is also mailed upon request or depending on your application setup.

No. You must wait until you receive the official Certificate of Authorization and Code Symbol Stamp. Fabrication before approval is not Code-compliant.

You must submit a Corrective Action Plan addressing the findings. Certification will be held until your responses are reviewed and accepted by the Team Leader.

Each finding must be answered with a clear explanation of the root cause, correction taken, and how you will prevent recurrence. Documentation is required.

The ASME Team Leader evaluates your responses and determines whether the corrective actions are acceptable. Your AIA may assist in preparing the reply.

You may formally appeal the finding through ASME. Supporting documentation must be provided. Appeals are reviewed by ASME’s Conformity Assessment Committee.

ASME Certificates are valid for 3 years from the date of issue. A new Joint Review is required for renewal.

Yes. ASME typically sends out renewal reminders in advance. However, it’s the organization’s responsibility to track and initiate the renewal process.

Yes. You must notify ASME and your AIA of the change. Depending on the nature of the change, a review or audit may be required.

Yes. You must notify ASME and your AIA of the change. Depending on the nature of the change, a review or audit may be required.

You must maintain Code compliance, follow your approved QC Manual, involve the AI on all stamped jobs, and ensure ongoing welder/NDE qualifications and documentation control.

No. There’s no requirement to notify ASME. However, your AIA and AI must be involved from the start of any Code-stamped fabrication.

Yes. The Code Symbol Stamp must be stored securely, accessible only by authorized personnel, and logged any time it is used on a pressure-retaining item.

After fabrication, your AI will complete the Manufacturer’s Data Report, and you may choose to register the vessel with the National Board, if required by jurisdiction.

Misuse — such as stamping before AI sign-off, using the stamp on non-Code items, or stamping out of scope — can result in suspension or revocation of your certification.

Yes, but only in accordance with ASME's branding policy. You may state you are an ASME Certificate Holder, but cannot suggest ASME endorsement of your company.

No. ASME certification is site-specific. Each physical location must apply separately and undergo its own Joint Review.

You must notify your AIA and coordinate reassignment. Fabrication requiring AI involvement cannot proceed without an assigned and available inspector.

Field audits are shorter, unannounced or scheduled spot-checks conducted between Joint Reviews to verify that Code practices are being followed continuously.

You must retain your QC Manual, PQRs, WPQs, calibration records, nonconformance logs, and a copy of each ASME-stamped item’s Data Report per the retention policy in your QC system.

ASME allows you to schedule a renewal review up to six months before expiration. This helps prevent certification gaps and allows time to resolve findings if needed.

No. If your Certificate expires before a successful review, you must stop Code fabrication and undergo a full new application process to regain certification.

Yes. You must maintain job records showing the item stamped, AI involvement, applicable procedures, traveler documentation, and inspection/testing data.

Yes. You must submit a supplemental application, update your QC Manual accordingly, and may be required to complete another Joint Review or audit.

Notify ASME and your AIA, revise your QC system to reflect the new scope, and schedule a scope expansion review if required.

Your Authorized Inspection Agency (AIA) is your first point of contact. You may also reach out to ASME’s Conformity Assessment Department via CA Connect.

Common causes include unauthorized use of the stamp, unreported AI changes, systemic quality failures, or falsified documentation.

Yes. You must notify ASME in writing and return your Code Symbol Stamp. Future participation will require reapplication and a new review.

ASME must be notified. A name change or ownership transfer may require review or administrative updates, depending on how operations are affected.

Incomplete or inconsistent implementation of the Quality Control Manual — such as procedures not being followed in practice — is one of the most common findings.

Yes. Missing or incomplete sign-offs on travelers, weld maps, or NDE reports can result in a finding, as it shows a breakdown in procedural control.

Frequently. Findings often result from outdated, missing, or improperly tracked calibration logs for inspection or testing equipment.

Yes. The QC Manual must clearly define who is responsible for each Code activity. Ambiguity in roles is a common documentation weakness.

That’s a frequent oversight. If your system doesn’t document how you evaluate and approve subcontracted services, expect a finding.

Yes. If your QC Manual or procedures include outdated or unused content, the review team may question whether your system reflects actual practice.

Missing logs, outdated entries, or failing to document activity within the required six-month window are all frequent issues.

It’s a serious finding, especially if the missing documentation relates to your demonstration weld. Certification may be delayed until resolved.

Yes, especially if it shows a lack of review or procedure adherence. The issue itself may be minor, but the system failure it exposes is what triggers the finding.

You may receive findings related to insufficient scope, inadequate documentation, or failure to demonstrate Code controls in action.

That’s a common finding. Welder IDs must be clearly traceable from traveler records to physical work — mismatches indicate a failure in traceability.

Yes. Either missing, misapplied, or undocumented hold points can lead to findings. They must match your QC Manual and be signed off appropriately.

Yes. If your team performs activities that aren’t covered in your written system, the review team may issue a finding for undocumented or uncontrolled processes.

Lack of documented resolution, failure to identify the root cause, or absence of corrective action are common reasons for NCR-related findings.

Definitely. Using the stamp before AI sign-off or outside approved scope is a serious violation and could trigger suspension of certification.

Yes. If your AI isn’t shown to be involved at required hold points, or if records don’t support their participation, it will result in a finding.

That’s not an acceptable defense during a review. Practices must align with your written QC system and the ASME Code — not habit or tradition.

Absolutely. Welder Performance Qualifications (WPQs) must be current, complete, and available during the review — especially for demo welders.

Referencing outdated Code requirements or editions can result in findings. Your documentation must reflect the current BPVC edition in effect.

Provide a clear, written corrective action showing the root cause, your fix, and how you’ll prevent recurrence — with documentation to back it up.

Yes. All forms — including weld logs, calibration sheets, and travelers — must be controlled under your QC system to ensure version accuracy and traceability.

No. All procedures used for Code activities must be written, controlled, and accessible. Verbal instructions are not considered compliant.

That’s a common cause of confusion and findings. Terms like “hold point,” “traveler,” or “final inspection” must match across documents and be clearly defined.

Yes. If the AI is unfamiliar with your system, has missed required involvement, or fails to meet ASME expectations, the review team may issue a finding related to AI performance.

Tools that are overdue or without traceable calibration will result in a finding and may call your inspection credibility into question.

Not necessarily. It’s okay to check documents, but your team should know how to access the answer and show ownership of the system.

Strongly recommended. Pre-audits help identify and fix gaps before reviewers find them. Skipping this step often leads to unnecessary findings.

Poor preparation — such as missing documents, unqualified personnel, or incomplete steps during the demo — is the leading cause of demo-related issues.

You may request clarification or formally appeal, but findings must still be addressed in your corrective action response unless withdrawn by the Team Leader.

Practice your demo, audit your system ahead of time, involve your AI early, and make sure your team is fluent in the QC Manual — not just reading it, but using it.

Looking for NBIC (National Board Inspection Code) FAQ?

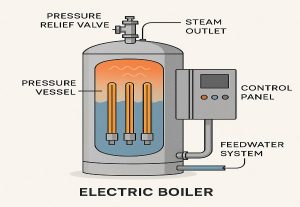

Electric Boilers Explained

Electric boilers use electricity to generate steam or hot water...

Read More