Browse Through Our Vessel Information Database

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors.

- API Tanks (2)

- ASME (6)

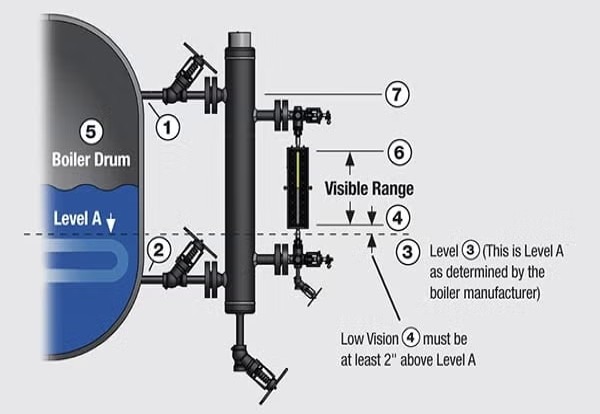

- Boiler (15)

- Dehydration Unit (5)

- Fabrication (14)

- Heat Exchangers (22)

- Air-Cooled Heat Exchangers (5)

- Compact Heat Exchangers (4)

- Other Heat Exchangers (9)

- Shell and Tube Heat Exchangers (4)

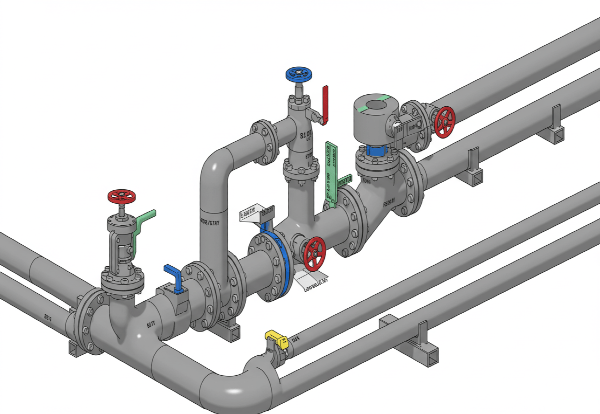

- Piping (4)

- Production Drawings (1)

- Repair and Alteration (2)

- Separators (23)

- Gas Separator (4)

- Liquid Separators (1)

- Magnetic Separators (1)

- Sand Separators (6)

- Three Phase Separators (7)

- Two Phase Separators (5)

- Stamps (15)

- H Stamp (2)

- Joint Review (2)

- PP Stamp (1)

- S Stamp (7)

- U Stamp (7)

- U2 Stamp (2)

- UM Stamp (2)

- Training Videos (1)

- Vessel Knowledge (90)

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

A U-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a pressure vessel has been manufactured and inspected in accordance with the rigorous standards outlined in the ASME® Boiler and Pressure Vessel Code...

In industrial operations, boiler downtime isn’t just an inconvenience—it’s a profit killer. Whether it’s lost production, emergency repair costs, or compliance penalties, a boiler failure can have far-reaching impacts. Fortunately, many of these issues are preventable with a strong, proactive maintenance strategy. In this...

Radiographic Testing (RT) is a powerful NDE technique widely used in the manufacturing of pressure vessels and boilers. It involves the use of ionizing radiation to penetrate the material and create an image of internal features.

Applicants for new issuance or renewal of an ASME® Certificate(s) of Authorization should be aware that the Joint Review will require implementation and demonstration of their Quality Control Program. The purpose of the demonstration is to have the Applicant provide evidence of their knowledge...

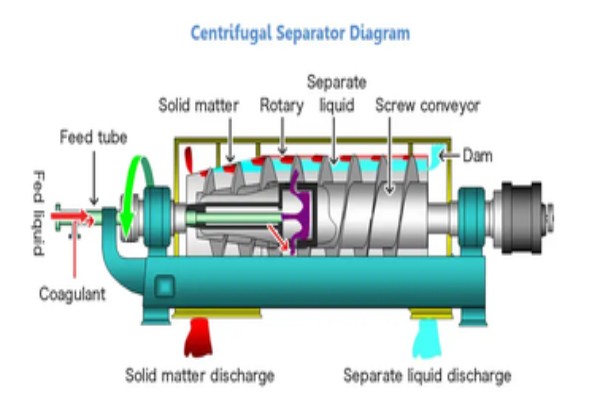

A centrifugal separator typically consists of a rotating bowl or drum. The fluid mixture is introduced into the bowl, and as the bowl spins, the centrifugal force causes the denser particles to move towards the outer wall, while the lighter fluid remains near the...

Non-Destructive Examination (NDE) is a crucial aspect of the manufacturing process for pressure vessels and boilers. It involves a variety of techniques to detect flaws and defects without damaging the material. For U-Stamp certified products, NDE is essential to ensure the integrity and safety...

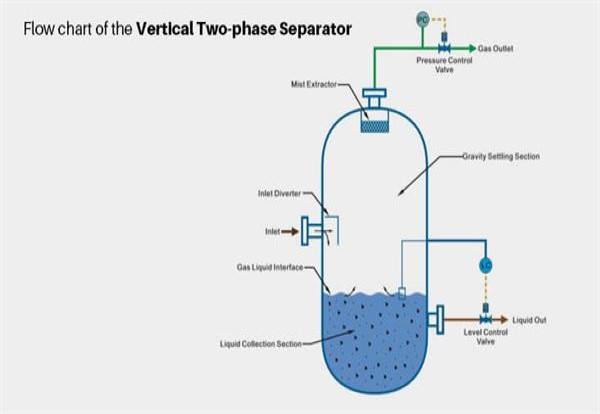

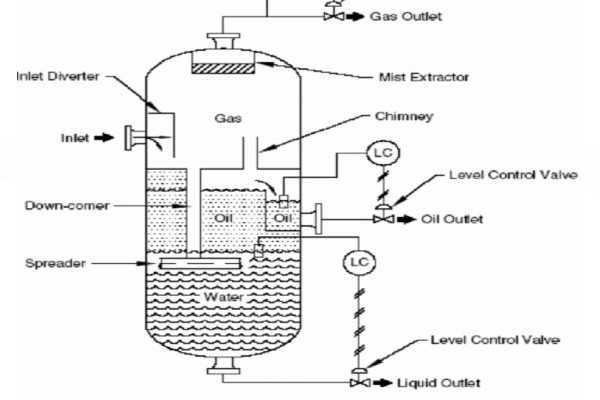

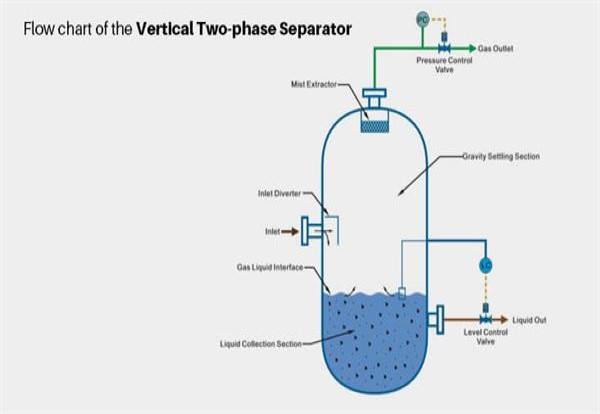

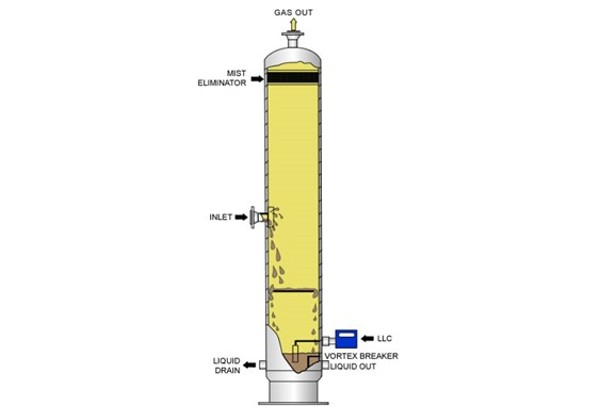

A vertical separator is a cylindrical vessel that is oriented vertically. When a gas-liquid mixture enters the separator, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top. The liquid phase is then drawn off through a...

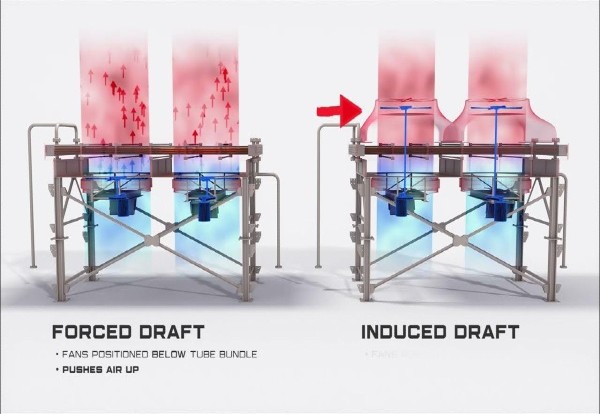

Air-cooled heat exchangers typically consist of a bundle of tubes through which the process fluid flows. Fins are attached to the tubes to increase the surface area for heat transfer. Air is forced or drawn across the finned tubes, removing heat from the process...

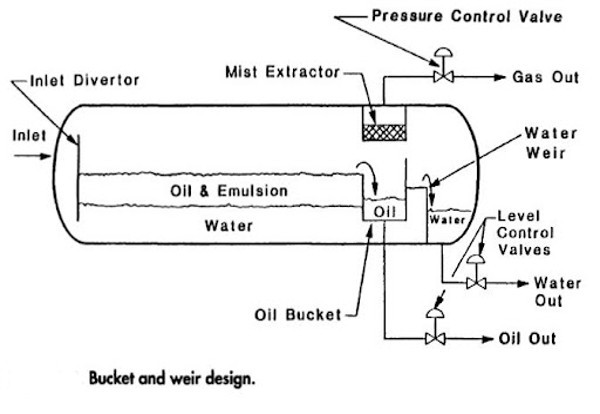

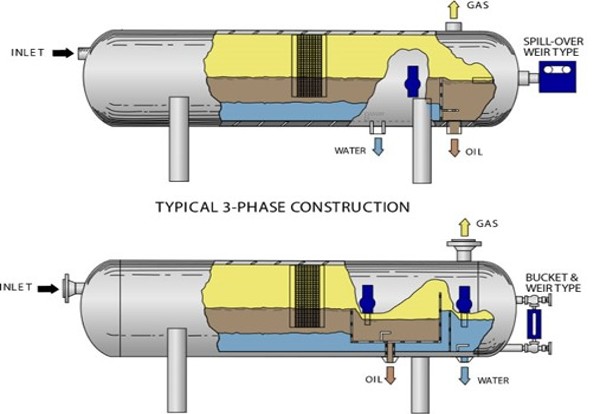

In a horizontal three-phase separator with an oil bucket and water weir, the vessel does not require an active interface controller. As the oil separates on top of the water it spills over the weir plate and into the oil bucket. The oil level...

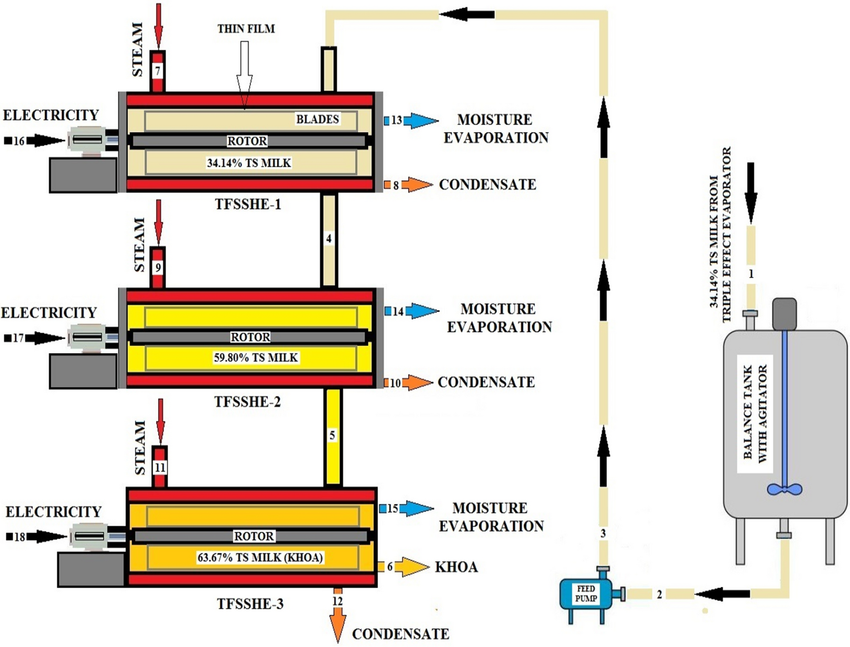

A scraped surface heat exchanger consists of a cylindrical shell with a rotating shaft inside. The shaft is fitted with blades or scrapers that continuously scrape the inner surface of the shell. This scraping action prevents the formation of product buildup on the heat...

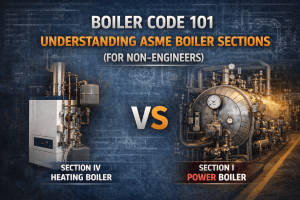

Learn how heating boilers unintentionally cross into ASME Section I power boiler classification, what inspectors look for, and how to avoid costly compliance surprises.

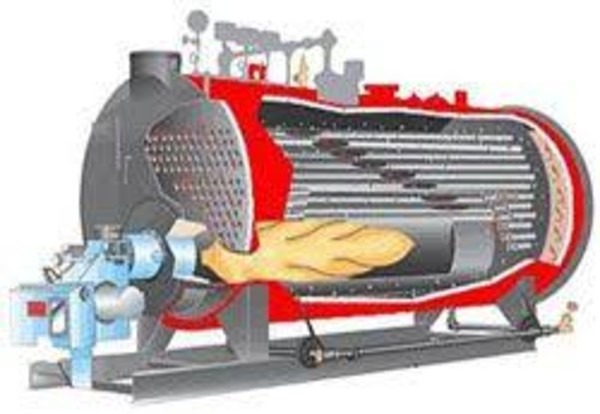

Industrial boilers are the beating heart of countless facilities—from chemical plants and refineries to food processing and textile mills. But not all boilers are created equal.

ASME Section I of the Boiler and Pressure Vessel Code (BPVC) governs the design, construction, and certification of power boilers—the heavy hitters used to generate steam or high‑temperature water for power generation, industrial processes, and large facilities. This section exists for one reason above...

The ASME® BPVC specifies a range of materials that are suitable for use in pressure vessels and boilers. These materials are often listed in the ASME® Boiler and Pressure Vessel Code, Section II, Part A, and other relevant standards

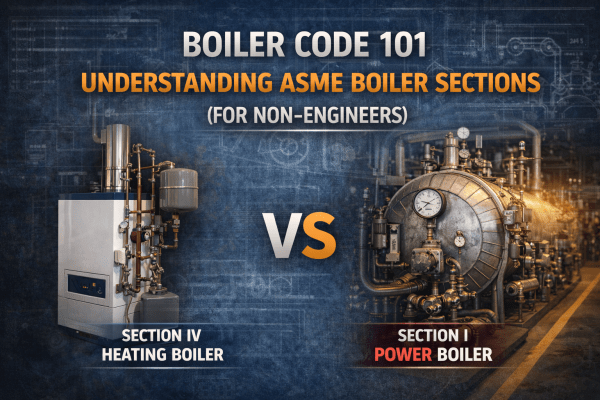

ASME boiler codes can sound intimidating, especially if you’re not an engineer by trade. The good news? You don’t need to memorize the Code to understand the basics. You just need a clear map.

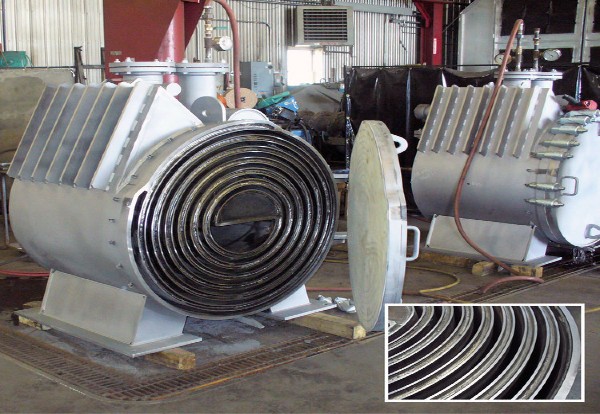

A spiral heat exchanger consists of two spiral-wound channels, one for each fluid. The two channels are separated by a partition, and the fluids flow in opposite directions through the channels. This counter-current flow arrangement maximizes heat transfer efficiency. Spiral heat exchangers are a...

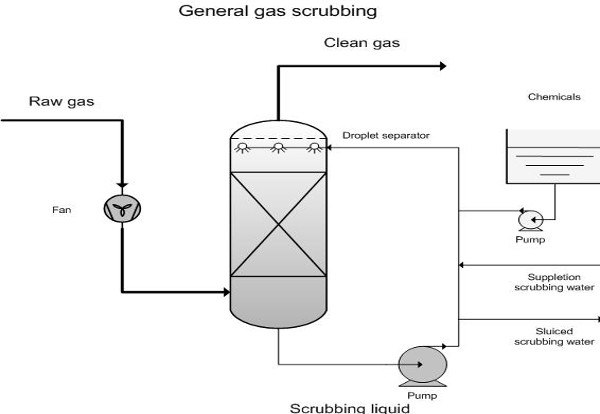

Stringent regulations on air pollution are being implemented globally, urging companies to adopt necessary measures. Gas scrubbers are legally mandated in industries where employees are exposed to potentially contaminated gases, making them a widely employed method for pollution control.

What is a Three-Phase Separator? A three-phase separator uses gravity to separate produced well fluid into gas, oil, and water phases. Installation of these vessels occurs near the wellhead, and they come in horizontal and vertical configurations. Produced well fluids consist of various amounts...

If the S-Stamp is the finish line, the Authorized Inspector (AI) is the gatekeeper holding the stopwatch. Before that stamp ever touches a boiler, inspectors are verifying far more than weld quality or paperwork completeness. They’re answering one critical question:

A boiler is only as healthy as the water that feeds it. Without proper treatment, boiler feedwater can quietly degrade system performance, corrode metal surfaces, and drastically reduce equipment lifespan.

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with interface control, is a particularly efficient design for maintaining...

Browse Through Our Vessel Information Database Below

Dive into the world of pressure vessel description with collection of informative blogs. Explore the intricacies of design, manufacturing, and applications for a wide range of pressure vessels, from industrial boilers to high-pressure reactors. Gain valuable insights into safety regulations, maintenance best practices, and the latest advancements in pressure vessel technology. Whether you’re an industry professional, a student, or simply curious about these critical components, our blog section offers a wealth of knowledge and resources.

Our Blog Site is still in progress. Keep checking back for more!

- See All Articles

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

A U-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a pressure vessel has been manufactured and inspected in accordance with the rigorous standards outlined in the ASME® Boiler and Pressure Vessel Code...

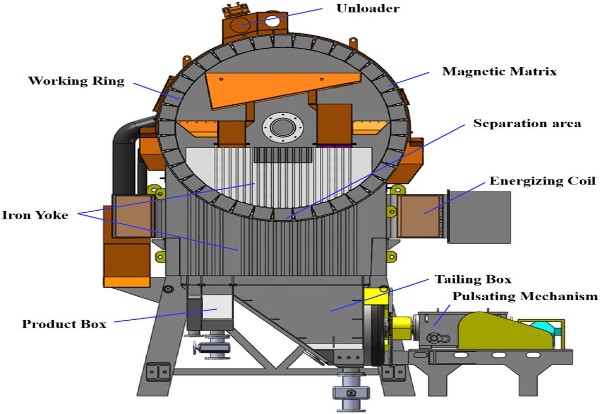

Magnetic separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing. Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of...

ASME® Section VIII, Division 1 provides the foundational framework for designing, constructing, and inspecting pressure vessels.

Stress analysis is a critical aspect of B31.1 piping design, ensuring that the piping system can withstand the various loads and pressures it will experience during operation.

A vertical separator is a cylindrical vessel that is oriented vertically. When a gas-liquid mixture enters the separator, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top. The liquid phase is then drawn off through a...

When it comes to industrial boilers, cutting corners isn't just risky—it’s illegal. Code compliance isn’t a formality; it’s a matter of safety, liability, and operational approval.

A forced draft air cooler typically consists of a bundle of finned tubes arranged in a specific configuration. The process fluid flows through the tubes, while air is forced across the fins by fans. The heat from the process fluid is transferred to the...

Depending on the specific application and the vapor-liquid mixture being separated, two-phase vessels can be oriented vertically or horizontally. In their simplest form, they are an empty tank that are used to reduce the velocity of a fluid on entry, thus allowing the liquid...

Obtaining and maintaining multiple ASME® Stamp Certificates of Authorization (COAs) can be a complex endeavor for manufacturers and fabricators. This blog post will delve into the challenges and strategies associated with managing multiple COAs, focusing on the ASME® Boiler and Pressure Vessel Code (BPVC).

Microchannel heat exchangers are a type of heat exchanger with channels that have characteristic dimensions in the micrometer range. These tiny channels offer significant advantages in terms of heat transfer efficiency and compact design. In a microchannel heat exchanger, the two fluids flow through...

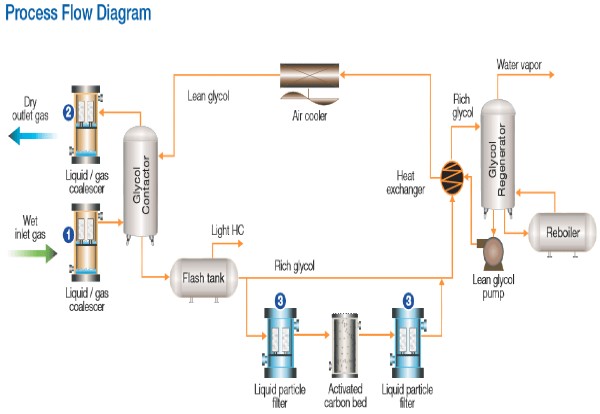

The temperature of the glycol entering the contactor has a significant effect on the gas dew point depression and should be held to within 10oF above the inlet gas temperature. Higher glycol losses and higher outlet gas dew points occur when the lean glycol...

A UM-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It authorizes a manufacturer to repair and alter existing pressure vessels and boilers. This certification ensures that repairs and alterations are performed in accordance with the...

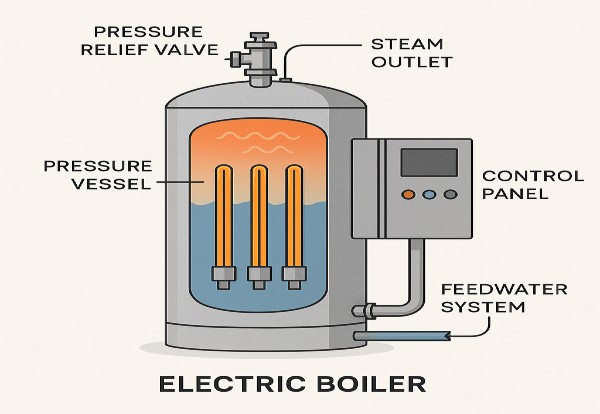

Electric boilers use electricity to generate steam or hot water — eliminating the need for fuel combustion. Unlike traditional boilers, there are no burners, gas valves, or flue stacks. Heat is generated through electrical resistance or electrode-type elements, making them clean, quiet, and often...

We perform detailed pressure vessel calculations in accordance with ASME® Section VIII, Division 1 and Division 2, ensuring optimal design for your specific application. This includes calculations for thickness, pressure, temperature, and external loads.

Certification is a pinnacle achievement for fabrication shops, signifying a commitment to excellence and adherence to rigorous quality standards. This distinction sets certified shops apart from those lacking formal documentation, solidifying their reputation for producing world-class products.

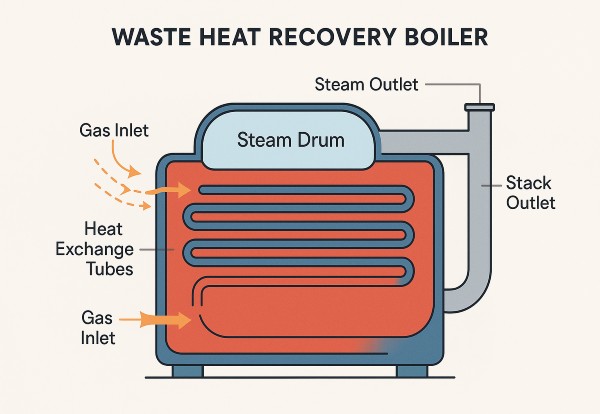

Waste heat recovery boilers (WHRBs) capture hot exhaust gases from industrial processes or engines and use that heat to generate steam or hot water — without burning additional fuel.

A U2-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It authorizes a manufacturer to repair and alter existing pressure vessels and boilers. This certification ensures that repairs and alterations are performed in accordance with the...

Sand separators are crucial components in various industries, including oil and gas, water treatment, and manufacturing. They are designed to remove solid particles, such as sand, dirt, and scale, from liquid streams. The choice of sand separator depends on various factors, including the type...

Go into your Joint Review with confidence. Use our Pre-Joint Review checklist to help determine if you have what you need or just get you on the track.

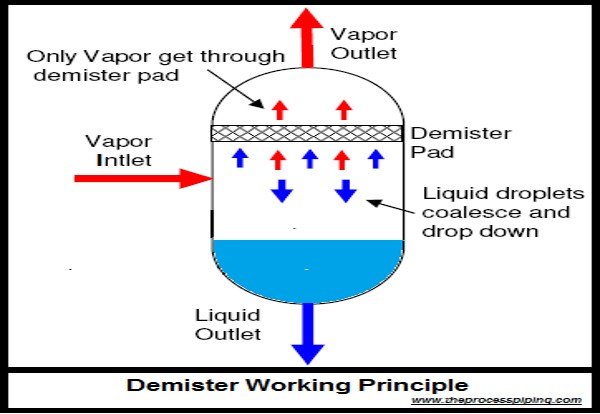

A demister is also known as a demister pad, mist pad, wire mesh demister, mesh mist eliminator, catching mist, and mist eliminator. It is a device often fitted to vapor–liquid separator vessels to enhance the removal of liquid droplets entrained in a vapor stream.

Compact heat exchangers are a type of heat exchanger designed to provide a high heat transfer rate in a small footprint. They are commonly used in applications where space is limited, such as in aerospace, automotive, and electronics industries.

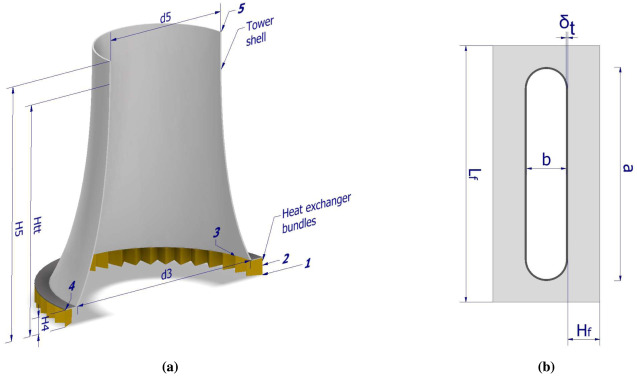

A natural draft air cooler typically consists of a tall, tower-like structure with a large number of finned tubes. The hot process fluid flows through the tubes, and the heat is transferred to the surrounding air. The heated air rises due to natural convection,...