Certification is a pinnacle achievement for fabrication shops, signifying a...

Read MoreFAQ

NBIC (National Board Inspection Code) FAQ

Explore the most common NBIC questionsrom General FAQ, In-Service Inspection Requirements, Repairs & Alterations, Documentation & R-Stamp Process, Common Issues & Jurisdiction Concerns

The NBIC, or National Board Inspection Code, is a set of rules and guidelines for the inspection, repair, alteration, and re-rating of pressure-retaining items after they are placed into service.

The NBIC is published by the National Board of Boiler and Pressure Vessel Inspectors and is updated every two years with input from industry experts, jurisdictions, and inspectors.

The NBIC provides a standardized framework for ensuring the continued safety of boilers and pressure vessels after fabrication, covering inspections, repairs, and alterations.

Yes — in most U.S. jurisdictions, NBIC compliance is legally required for repairs and alterations to ASME-stamped pressure-retaining items.

| • Part 1 – Installation | |||

| • Part 2 – In-Service Inspection | |||

| • Part 3 – Repairs and Alterations | |||

| • Part 4 – Pressure Relief Devices | |||

It applies to boilers, pressure vessels, and piping systems that were built to ASME Code and are currently in service, including those registered with the National Board.

ASME governs new construction. NBIC governs equipment after it is placed in service, including inspection, repair, and alteration procedures.

NBIC requirements are enforced by jurisdictions, such as state or provincial boiler boards, which adopt the Code into law.

The NBIC is primarily used in the United States and Canada, but it may be accepted in other regions if adopted by the local authority or specified by contract.

No. To perform Code-compliant repairs or alterations, a company must hold a valid R Certificate of Authorization and be inspected by a National Board-Commissioned Inspector.

It’s a unique registration number assigned by the National Board to ASME-stamped equipment. It links the item to its original Manufacturer’s Data Report and ensures traceability for in-service work.

A National Board-Commissioned Inspector is authorized to verify repairs and alterations under the NBIC. They must be certified through the National Board and affiliated with an Authorized Inspection Agency (AIA).

It’s a certificate issued by the National Board allowing a company to perform repairs and alterations to pressure-retaining items in accordance with the NBIC.

An R Certificate is valid for three years, after which the organization must undergo a renewal review with the National Board and their AIA.

Yes. The R Certificate is issued after a successful Joint Review conducted by the National Board and your AIA to verify your repair program and demonstration.

A repair restores the item to its original design, while an alteration changes the original design — such as increasing pressure, changing materials, or adding new nozzles.

Rerating changes the pressure or temperature limits of a vessel without modifying the physical structure. It requires engineering review and inspector verification.

Only if the owner holds an R Certificate or is working under a jurisdiction-approved repair program. Otherwise, the repair must be performed by an authorized R-stamp holder.

In some cases, yes — but the inspector must verify Code construction, and the jurisdiction must approve. Registration is highly recommended for traceability and legality.

R-1 is the official NBIC form used to document repairs to pressure-retaining items. It includes data on the equipment, scope of work, materials, and inspection verification.

R-2 documents alterations — any physical or design change that differs from the original construction. It requires engineering justification and inspection sign-off.

R-3 is used for nameplate replacement, relocation, or part replacement not involving pressure boundary welds — typically non-pressure-retaining components.

The repair organization, the Authorized Inspector, and in some cases the jurisdictional authority all sign the completed R-Form before it is submitted.

Yes. Most National Board forms can be filled and submitted through the National Board’s online portal, streamlining registration and documentation.

No. The NBIC applies to boilers, pressure vessels, and piping that were built to ASME Code and are in service. Relief valves are covered under Part 4.

Yes. NBIC Part 4 governs the inspection, testing, and repair of pressure relief valves. Organizations performing valve work must have VR certification.

It means the pressure-retaining item has been registered with the National Board, and a NB number and copy of the Manufacturer’s Data Report are on file.

Yes. Field repairs are allowed if the organization has field capabilities in their QC system, and the AI witnesses applicable steps per NBIC requirements.

No. Code Cases apply to ASME Code construction only. The NBIC does not issue Code Cases, but may reference ASME Code interpretations or guidance.

The NBIC is revised every two years by the National Board Inspection Code Committee, which includes industry, jurisdiction, and inspector representatives.

In-service inspection ensures that boilers and pressure vessels remain safe for continued operation by detecting deterioration, corrosion, cracking, or mechanical damage.

NBIC Part 2 provides requirements and guidance for inspecting pressure-retaining items after they are placed in service.

Only Authorized Inspectors or Authorized Inspection Agencies recognized by the jurisdiction may perform Code-compliant in-service inspections.

Inspection frequency depends on the jurisdiction and equipment type, but many boilers and pressure vessels are inspected annually or biennially.

External inspections are visual checks done while the unit is operating. Internal inspections require shutdown and vessel access to examine internal surfaces and components.

Yes. Ultrasonic thickness testing (UT) is often required to monitor corrosion rates and determine remaining wall thickness in vessels and piping.

A Condition Report documents the results of an in-service inspection, including observed damage, corrosion, deformation, or any indication of unsafe operating conditions.

Inspectors look for corrosion, erosion, leakage, cracking, bulging, deformation, loose supports, and signs of pressure relief device malfunction.

The most common include corrosion under insulation (CUI), pitting, wall thinning, weld cracking, leaks at nozzles, and overpressure events that affect relief devices.

Only if allowed by the jurisdiction and if the owner holds a Certificate of Competency or contracts with an authorized inspection agency.

The inspector assesses mechanical integrity, identifies unsafe conditions, verifies Code compliance, and recommends repairs, alterations, or re-rating as needed.

MRT is calculated using original design formulas from the ASME Code, adjusted for corrosion allowance and future service life expectations.

The vessel must be removed from service, repaired, re-rated, or replaced based on engineering evaluation and inspector judgment.

It’s an engineering analysis that evaluates whether a degraded component can safely continue operating, often using API 579 or NBIC Appendix C.

Yes. NBIC Part 4 requires regular inspection, testing, and verification that devices are properly set, reseat correctly, and are not leaking or plugged.

Yes — and in most cases, internal inspections must be performed during planned shutdowns to safely access internal components.

Yes. Techniques like UT, MT, PT, and RT are used to assess defects that are not visible during routine visual inspections.

Insulation may need to be removed or cut away at key inspection points to check for corrosion under insulation (CUI) or verify nozzle weld condition.

An Inspection Plan outlines what components will be inspected, the methods used, required access, safety precautions, and documentation expectations.

The inspector may recommend alternative inspection methods such as remote visual tools, spot UT, or a detailed external review — with jurisdiction approval.

If the equipment is temporarily out of service, inspection may be deferred. If permanently retired, it should be clearly labeled and disconnected from operation.

Look for bulging, deformed heads, distorted gaskets, cracked nozzles, or popped relief valves — any of which may indicate pressure excursions.

Any active leak in a pressure boundary is considered a safety risk and must be evaluated immediately for removal from service or repair.

Jurisdictions set minimum intervals, but risk-based strategies and past inspection history may influence more frequent evaluations in critical service.

Yes. Even if wall loss isn’t critical, localized pitting, rust jacking, or CUI can compromise supports or lead to future failure and must be addressed.

The inspector verifies thickness data, engineering calculations, and documentation before signing off on a new pressure-temperature rating.

Yes. Structural supports, anchors, and hangers must be checked for cracks, corrosion, and alignment — even if they aren’t pressure-retaining.

The inspector may condemn the device and recommend immediate replacement or testing before the vessel is allowed back into service.

It’s a compiled record of inspection findings, thickness readings, corrective actions, recommendations, and overall fitness of the equipment.

A jurisdictionally required inspection must be performed on schedule and reported to the state or provincial boiler board using official procedures.

A repair restores a pressure-retaining item to its original design — such as replacing a corroded shell section, rewelding a nozzle, or fixing a leak without changing vessel performance.

An alteration changes the original design — like increasing MAWP, replacing a head with a different geometry, or adding a new nozzle not shown on the original Data Report.

A temporary repair is an interim fix allowed under controlled conditions with jurisdiction approval. A permanent repair fully complies with NBIC and Code expectations.

The Authorized Inspector (AI) must review the repair plan, verify compliance, and witness key steps. The jurisdiction may also require approval for certain repairs.

Not always. Routine repairs like weld buildup or pad replacement may not need engineering. However, alterations and rerates always require engineering analysis.

Yes — under NBIC rules for in-service or hot work repairs, but only with proper safety precautions, AI oversight, and often jurisdictional approval.

No. That’s considered an alteration because it changes the original design intent. It must follow alteration procedures and be documented on a Form R-2.

Shell plate replacement, nozzle rewelding, and leak repairs from corrosion or erosion are among the most common NBIC-covered repairs.

Only if permitted by your procedure, approved by the AI, and does not alter the original design. Full NDE and documentation are required post-repair.

It depends on material, thickness, and original Code requirements. PWHT must match the original construction rules or be justified by engineering analysis.

Yes — if the repair involves pressure boundary welding, it must be performed by an R-stamp holder under NBIC guidelines with inspector oversight.

Yes, if the replacement is identical in size, shape, and material to the original. If any design conditions change, it becomes an alteration.

The defective area must be removed, cleaned, and prepped per your written procedure. All base metal must be sound, and surfaces dry and free of contaminants.

Yes, but it must follow NBIC rules, and the AI must verify compliance. Some jurisdictions may impose additional requirements for power boilers.

Yes. Components like insulation supports, ladders, or nameplate frames may be repaired outside NBIC scope, but care must be taken not to affect the pressure boundary.

Yes — these are called in-service repairs, and they must follow strict NBIC guidelines for safety, isolation, and inspection. AI and jurisdiction approval is typically required.

Possibly — only if the removed material does not reduce thickness below Code minimums, and the area passes NDE to confirm flaw removal.

Yes, if used to restore thickness or prevent corrosion. Weld overlays must be approved by the AI and meet original Code material compatibility.

When the original nameplate is damaged or missing, a repair nameplate may be affixed under NBIC rules, referencing the R-Form and identifying the repair organization.

Only if it meets ASME Section II, is compatible with the original design, and the AI and engineer approve the substitution.

You must document the deviation, evaluate the impact, and possibly rework the repair or submit engineering justification — depending on severity.

Yes. Temporary repairs must be documented separately, marked clearly on the vessel or report, and scheduled for permanent replacement.

Yes — but only after a full engineering analysis, jurisdiction approval, inspector verification, and completion of a Form R-2.

Most do — especially if pressure boundary welds are involved. However, in some cases, pneumatic testing may be allowed with justification.

Multiple repairs can be grouped on a single R-1 form, if they are part of the same job and properly described with supporting documentation.

Yes — but this is considered an alteration, as it changes the design configuration. Form R-2 and inspector sign-off are required.

Rerating (changing pressure/temperature limits) is an alteration, even if no physical work is done. It requires engineering and jurisdiction approval.

You must use engineering evaluation to establish new design basis, possibly re-rate the item, and document everything under NBIC procedures.

Yes — if they are full-penetration welded, approved by the AI, meet minimum thickness, and follow NBIC acceptance criteria.

Not under the R Stamp — relief devices are covered under NBIC Part 4 and require a VR Stamp for certified repair.

You’ll need a completed Form R-1, the traveler, welding documentation (WPS/PQR/WPQ), material traceability, NDE results, and inspector sign-offs.

R-1 documents repairs that restore original design. It must be completed and signed by the repair organization and Authorized Inspector (AI).

R-2 documents alterations, such as changes to pressure rating, material, or design configuration. It requires engineering evaluation and AI approval.

R-3 is used when replacing or relocating the nameplate, or documenting non-pressure part replacements — usually when original identification is lost or damaged.

The repair organization fills out the R-Form, but it must be reviewed and signed by the AI before the repair is considered compliant.

Only for Code repairs involving pressure-retaining items. Cosmetic or support structure work may not require R documentation.

Equipment info, National Board number, original Code stamp, repair scope, materials used, WPS info, NDE methods, AI details, and signatures.

Yes. The National Board accepts digital submission of R-Forms through their online portal, and many jurisdictions encourage it.

They are assigned a unique job number by the repair organization, which must be traceable through their internal records.

Yes — within 90 days of completing the work, unless otherwise directed by the jurisdiction.

It is a metal tag affixed next to the original nameplate indicating that a repair or alteration was completed under NBIC and R-stamp certification.

The repair organization orders the nameplate, but it must be approved by the AI and engraved with details matching the R-Form.

It must list the repair org’s name, R-number, job number, date, and a description (e.g., “Repair to shell”). It cannot cover the original nameplate.

No — only if the original Code requires it and the pressure boundary has been disturbed. The need is determined by the scope and inspector.

All NDE must be recorded with technique sheets, acceptance criteria, technician certification, and results signed by a qualified examiner.

Yes, and it’s good practice. Many jurisdictions require a copy to be retained on site or submitted to the Authorized User.

The AI must verify design information via jurisdiction or National Board records. In some cases, an R-3 nameplate may be used to re-establish identity.

Absolutely not. The AI must review and sign the R-Form before the R-Stamp is applied. Early stamping is a major violation.

The repair must be corrected or reworked before the R-Form is signed. The AI has authority to reject noncompliant work.

At least 5 years, or longer if required by your QC Manual or the jurisdiction. Many companies keep them for the life of the equipment.

Yes, if all repairs are part of the same job and clearly described. Otherwise, separate forms should be used for traceability.

Late submission is a jurisdictional violation and may affect your certification. Always track submission deadlines closely.

Yes, as long as they meet NBIC requirements and are within the scope of your QC Manual. Section IX WPS/PQRs are commonly used.

Only if they are non-Code repairs or allowed by the jurisdiction. Otherwise, all pressure boundary repairs must follow NBIC and be R-stamped.

You must resubmit the corrected form with supporting documentation and obtain AI and jurisdiction approval for the revision.

Yes — the National Board accepts digital signatures, provided they meet system security and traceability requirements.

You should provide copies of R-Forms, material certs, and NDE reports upon request — especially for vessels that will be relocated or resold.

Yes — including address, R number, and authorized signatory. It must match the info registered with the National Board.

Yes — but the new AI must review all prior documentation, visit the site, and accept responsibility for final approval and signing.

A replacement must be requested, engraved with identical info, and reattached under AI supervision with a revised R-Form referencing the change.

Unreported or undocumented repairs — especially when pressure boundary work is performed without inspector involvement or proper R-Forms.

Not legally. Most jurisdictions require notification, documentation, and AI involvement for any NBIC-covered work.

Late or missing submissions may result in fines, certificate suspension, or jurisdictional penalties, depending on local regulations.

No. Only ASME can authorize use of the original Code Symbol. Repairs are documented separately with the R-Stamp nameplate, not restamping ASME marks.

Report it to the AI and jurisdiction. You may be required to evaluate, rework, or re-document the repair to bring it into NBIC compliance.

Yes. Owners are responsible for ensuring repairs are done by certified organizations and properly documented under NBIC.

Yes. The jurisdiction has final authority and may reject or require additional evaluation — even with inspector approval.

Never. All NBIC and Code activity must be documented through written procedures, forms, and inspector sign-off.

Undocumented repairs can trigger loss of coverage, jurisdictional fines, or mandatory shutdown until corrective action is taken.

Only if you are certified to work in that jurisdiction and have approval from both the AI and local authority.

No. Some jurisdictions adopt portions or modified versions of the NBIC, and others may have stricter rules. Always verify local requirements.

The repair will likely be invalidated, and you'll need to redo the work under inspector oversight. Premature welding is a common violation.

It means performing repairs that require NBIC documentation without being R-certified — a serious violation with certification consequences.

Every 3 years through a formal Joint Review, but field audits may occur more often — especially if issues are reported to the jurisdiction.

Yes. Repeated violations, falsified documentation, or failure to follow procedures can lead to suspension or revocation by the National Board.

The jurisdiction overrules the AI. If conflict arises, the AI should defer to jurisdictional requirements and escalate through formal channels if needed.

Ensuring material traceability and heat numbers are logged correctly on the traveler and R-Form. Small oversights can trigger big findings.

Yes — if scope or design intent changes mid-project. The R-Form must be updated, and additional engineering or inspection may be required.

Incomplete documentation, missing R-Forms, unclear scope of work, or starting repairs without prior jurisdiction notice.

Using incorrect set pressure, failing to reseat properly, or working on valves without VR certification — all jurisdictional red flags.

Often during in-service inspections, audits, or jurisdictional reviews — especially if welds or changes appear undocumented on the Data Report.

It’s treated as an unauthorized alteration. The jurisdiction may require engineering review, R-2 documentation, or full removal from service.

No. Welders must be qualified under Section IX and listed in the repair organization's QC system. No WPQ = noncompliant work.

Yes — if the work deviates from NBIC or approved procedures, the AI can halt repairs immediately and notify the jurisdiction.

Yes. Forms with missing info, wrong scope, improper signatures, or formatting issues may be returned and flagged.

Only with jurisdiction approval. If allowed, full documentation must still be created and submitted through NBIC channels.

That’s a major violation. Nameplates must never be obscured or removed unless officially replaced with an R-3 nameplate under AI supervision.

Yes. Some states require mobile repair units to be registered, and AI coordination is still required on-site. Always check local mobile work rules.

Yes. If the owner is R-certified, they may perform their own repairs under NBIC — as long as all rules, documentation, and inspector requirements are followed.

Communicate early and often — with your AI, the jurisdiction, and the National Board. No surprises = no shutdowns.

Looking for ASME Boiler & Pressure Vessel Code (BPVC) Q&A?

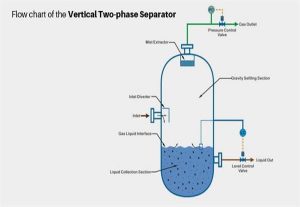

Two-Phase Vertical Separator

A vertical separator is a cylindrical vessel that is oriented...

Read MoreWhen a Heating Boiler Becomes a Power Boiler: ASME Section I vs IV Explained

Learn how heating boilers unintentionally cross into ASME Section I...

Read More