Certification is a pinnacle achievement for fabrication shops, signifying a commitment to excellence and adherence to rigorous quality standards. This distinction sets certified shops apart from those lacking formal documentation,...

Read MoreJoint Review Information

Joint Review Information

The main question & most important question is, how can Pressure Vessel Manufacturers become Stamp Holders? Below you can find more in-depth info to what you will need and what to expect with a Joint Review. We know the process from beginning to end can be a little confusing and stressful especially if this is your first Stamp, but we are here for you. Please feel free to ask us any questions or concerns you may have.

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

Understanding ASME® Joint Reviews Understanding ASME® Joint Reviews – Key Elements One of the most exemplary achievements a fabrication shop can attain is Certification, which indicates a level of quality that is superior to organizations with little or no documentation to prove their...

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

Applicant’s Guide for Certificates of Authorization Applicant’s Guide for Certificates of Authorization Certification is a pinnacle achievement for fabrication shops, signifying a commitment to excellence and adherence to rigorous quality standards. This distinction sets certified shops apart from those lacking formal documentation, solidifying their reputation for producing world-class products. These...

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

Applicants Applicants Requesting; New, Multiple, or Renewal Certification There are also a lot more questions you may have like, what is the Pressure Vessel certification process? Pressure Vessel manufacture certification is the same as the Authorization for the ASME® Stamp. The Pressure Vessel manufacturers can implement the Quality Control System...

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

Checklist Pre-Joint Review Checklist: The following is a list of items to verify prior to the Pre-Joint Review Audit. Please be advised that this list is general and does not cover all areas in detail. See below the articles to Download or Print the PDF for future use. Verify that...

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

AIA Organizations Holding Certificates Of Accreditation (AIA) From The American Society Of Mechanical Engineers This list is not to be considered an official listing of holders of AIA Certificates. AIA firms change frequently, and this list is updated frequently to stay on top of the changes. Your due diligence in...

- All

- API Tanks

- ASME

- Boiler

- Dehydration Unit

- Fabrication

- Heat Exchangers

- Piping

- Production Drawings

- Repair and Alteration

- Separators

- Stamps

- Training Videos

- Vessel Knowledge

- Back

- Shell and Tube Heat Exchangers

- Air-Cooled Heat Exchangers

- Compact Heat Exchangers

- Other Heat Exchangers

- Back

- Sand Separators

- Three Phase Separators

- Two Phase Separators

- Gas Separator

- Magnetic Separators

- Liquid Separators

- Back

- Joint Review

- U Stamp

- UM Stamp

- PP Stamp

- S Stamp

- U2 Stamp

- H Stamp

USA State Jurisdictions Information The following information is intended to help Manufactures with Jurisdictional knowledge, rules, regulations and the information you need We do our best to stay up to date with this information, but things change regularly; please use due diligence and give the chief a call to verify...

Pressure Vessel & Boiler Stamp Information

ASME Applicants Requesting; New, Multiple, or Renewal Certification

Applicants for new issuance or renewal of an ASME® Certificate(s) of Authorization should be aware that the Joint Review will require implementation and demonstration of their Quality Control Program. The...

Read MorePre-Joint Review Checklist

Go into your Joint Review with confidence. Use our Pre-Joint Review checklist to help determine if you have what you need or just get you on the track.

Read MoreRadiographic Testing (RT) for U-Stamp Certification

Radiographic Testing (RT) is a powerful NDE technique widely used in the manufacturing of pressure vessels and boilers. It involves the use of ionizing radiation to penetrate the material and...

Read MoreNon-Destructive Examination (NDE): A Critical Component of U-Stamp Certification

Non-Destructive Examination (NDE) is a crucial aspect of the manufacturing process for pressure vessels and boilers. It involves a variety of techniques to detect flaws and defects without damaging the...

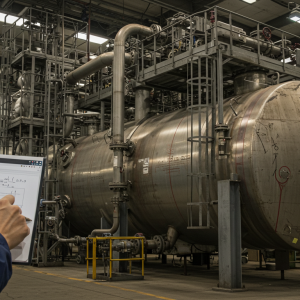

Read MoreU-Stamped Pressure Vessels: A Mark of Quality and Safety

A U-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a pressure vessel has been manufactured and inspected in...

Read MoreRecent Articles

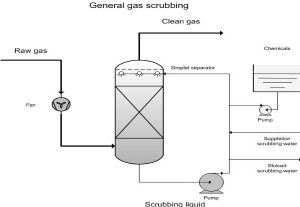

Gas Scrubber

Stringent regulations on air pollution are being implemented globally, urging companies to adopt necessary measures. Gas scrubbers are legally mandated in industries where employees are exposed to potentially contaminated gases,...

Read MoreDifferent Types of Sand Separators

Sand separators are crucial components in various industries, including oil and gas, water treatment, and manufacturing. They are designed to remove solid particles, such as sand, dirt, and scale, from...

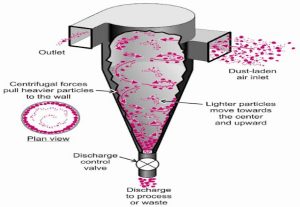

Read MoreCyclone Separators

Cyclone separators are a type of mechanical separator that uses centrifugal force to separate solid particles from a gas or liquid stream. They are widely used in various industries, including...

Read More