History of the National Board of Boiler

and Pressure Vessel Inspectors

A Century of Safety:

The History of the National Board of Boiler and Pressure Vessel Inspectors

The National Board of Boiler and Pressure Vessel Inspectors (NBBI) stands as a cornerstone of safety in the pressure equipment industry. Its journey, marked by innovation and collaboration, spans over a century.

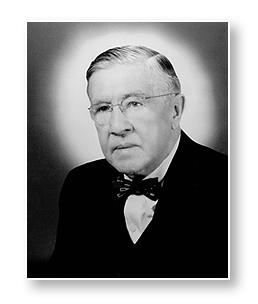

Pictured above: Carl O. Myers, Ohio’s chief boiler inspector

Early Years (1919-1940s):

- Formation: Recognizing the critical need for consistent safety standards across jurisdictions, Ohio Chief Inspector Carl Myers convened a meeting in 1919 with colleagues from other states. This pivotal gathering led to the establishment of the NBBI on December 2, 1919.

- Early Focus: The initial focus was on establishing uniform rules and regulations for the construction, installation, and inspection of boilers and pressure vessels. This aimed to prevent catastrophic failures that could result in loss of life and property.

- Collaboration with ASME: Recognizing the importance of engineering expertise, the NBBI forged a strong partnership with the American Society of Mechanical Engineers (ASME), collaborating on the development of the ASME Boiler and Pressure Vessel Code.

Mid-Century Growth (1950s-1970s):

- Expanding Scope: The NBBI’s responsibilities expanded beyond boilers to encompass a wider range of pressure equipment, including pressure vessels, piping systems, and nuclear components.

- Accreditation Programs: To ensure consistent quality and safety, the NBBI developed accreditation programs for:

- Inspection Agencies: To certify the competency of organizations performing inspections.

- Repair Organizations: To ensure the quality of repairs made to pressure equipment.

- Nuclear Inspector Training: To train and certify inspectors working in the nuclear industry.

- International Recognition: The NBBI’s influence, and standards gained international recognition, with many countries adopting its principles and guidelines.

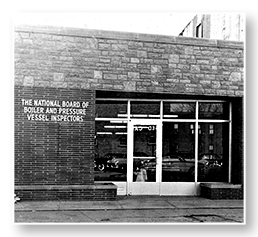

Pictured above: HQ of the National Board of Boiler and Pressure Vessel Inspectors

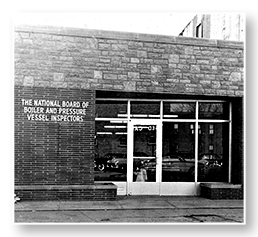

Pictured above: New HQ of the National Board of Boiler and Pressure Vessel Inspectors

Modern Era (1980s-Present):

- Technological Advancements: The NBBI continuously adapts to technological advancements in materials, manufacturing, and inspection techniques. This includes embracing new technologies like non-destructive testing (NDT) and computer-aided design (CAD).

- Focus on Risk Management: The emphasis shifted towards a more comprehensive approach to risk management, incorporating elements of risk assessment and probabilistic risk assessment.

- Continuing Education: The NBBI maintains a strong commitment to continuing education and training for inspectors, engineers, and other professionals in the pressure equipment industry.

Early Years (1919-1940s):

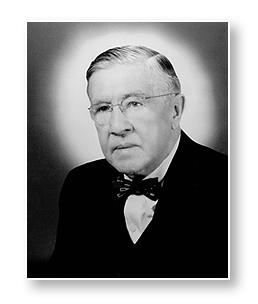

Pictured above: Carl O. Myers, Ohio’s chief boiler inspector

- Formation: Recognizing the critical need for consistent safety standards across jurisdictions, Ohio Chief Inspector Carl Myers convened a meeting in 1919 with colleagues from other states. This pivotal gathering led to the establishment of the NBBI on December 2, 1919.

- Early Focus: The initial focus was on establishing uniform rules and regulations for the construction, installation, and inspection of boilers and pressure vessels. This aimed to prevent catastrophic failures that could result in loss of life and property.

- Collaboration with ASME: Recognizing the importance of engineering expertise, the NBBI forged a strong partnership with the American Society of Mechanical Engineers (ASME), collaborating on the development of the ASME Boiler and Pressure Vessel Code.

Mid-Century Growth (1950s-1970s):

Pictured above: HQ of the National Board of Boiler and Pressure Vessel Inspectors

- Expanding Scope: The NBBI’s responsibilities expanded beyond boilers to encompass a wider range of pressure equipment, including pressure vessels, piping systems, and nuclear components.

- Accreditation Programs: To ensure consistent quality and safety, the NBBI developed accreditation programs for:

- Inspection Agencies: To certify the competency of organizations performing inspections.

- Repair Organizations: To ensure the quality of repairs made to pressure equipment.

- Nuclear Inspector Training: To train and certify inspectors working in the nuclear industry.

- International Recognition: The NBBI’s influence, and standards gained international recognition, with many countries adopting its principles and guidelines.

Modern Era (1980s-Present):

Pictured above: New HQ of the National Board of Boiler and Pressure Vessel Inspectors

- Technological Advancements: The NBBI continuously adapts to technological advancements in materials, manufacturing, and inspection techniques. This includes embracing new technologies like non-destructive testing (NDT) and computer-aided design (CAD).

- Focus on Risk Management: The emphasis shifted towards a more comprehensive approach to risk management, incorporating elements of risk assessment and probabilistic risk assessment.

- Continuing Education: The NBBI maintains a strong commitment to continuing education and training for inspectors, engineers, and other professionals in the pressure equipment industry.

NBBI

The NBBI has played a vital role in enhancing the safety of countless individuals and industries worldwide. Through its unwavering dedication to safety, collaboration with industry stakeholders, and continuous adaptation to evolving technologies, the NBBI continues to be a leader in pressure equipment safety.