Air-Cooled Heat Exchangers

A Versatile Solution for Heat Rejection

Air-cooled heat exchangers are a type of heat exchanger that uses ambient air to cool a process fluid. They are a popular choice for many industrial applications, particularly in areas where water is scarce or expensive.

Pictured above: Air-Cooled Heat Exchanger

How Air-Cooled Heat Exchangers Work

Air-cooled heat exchangers are a type of heat exchanger that uses ambient air to cool a process fluid. They are a popular choice for many industrial applications, particularly in areas where water is scarce or expensive.

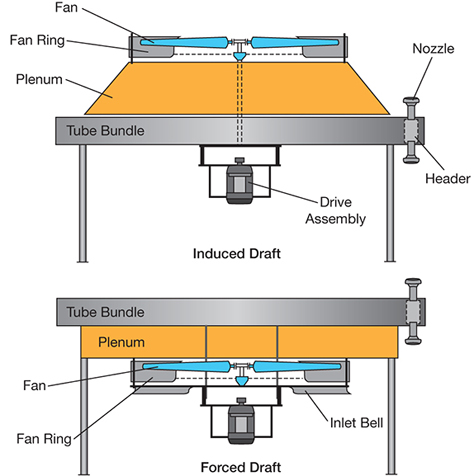

They typically consist of a bundle of tubes through which the process fluid flows. Fins are attached to the tubes to increase the surface area for heat transfer. Air is forced or drawn across the finned tubes, removing heat from the process fluid.

Pictured above: Air-Cooled Heat Exchanger – Figure Template Standard

Types of Air-Cooled Heat Exchangers:

- Forced Draft Air Coolers: Air is forced across the tubes by fans.

- Induced Draft Air Coolers: Air is drawn across the tubes by fans.

- Natural Draft Air Coolers: Air is drawn across the tubes by natural convection.

Key Design Considerations

- Tube Material: The tube material should be selected based on the fluid compatibility and temperature requirements.

- Fin Material: The fin material should have high thermal conductivity and corrosion resistance.

- Fin Geometry: The fin geometry, including fin height and spacing, affects the heat transfer performance.

- Fan Size and Power: The size and power of the fans determine the airflow rate and cooling capacity.

- Airflow Pattern: The airflow pattern across the tubes can influence the heat transfer efficiency.

- Thermal Hydraulic Design: The design of the heat exchanger must ensure adequate heat transfer and pressure drop.

Advantages vs Disadvantages of Air-Cooled Heat Exchangers:

Advantages

- Water Conservation: Reduces water consumption.

- Environmental Friendliness: No water discharge or thermal pollution.

- Flexibility: Can be designed for a wide range of capacities and temperature ranges.

- Low Maintenance: Relatively simple to maintain.

Disadvantages

- Larger Footprint: Requires more space than water-cooled heat exchangers.

- Sensitivity to Ambient Conditions: The cooling capacity can be affected by ambient air temperature and humidity.

- Higher Operating Costs: The energy consumption of the fans can increase operating costs.

Air-cooled heat exchangers are a versatile and reliable solution for heat rejection in many industrial applications. Their ability to operate without a water source makes them an attractive option in areas with water scarcity.

By carefully considering these factors, engineers can design air-cooled heat exchangers that meet the specific needs of a particular application.