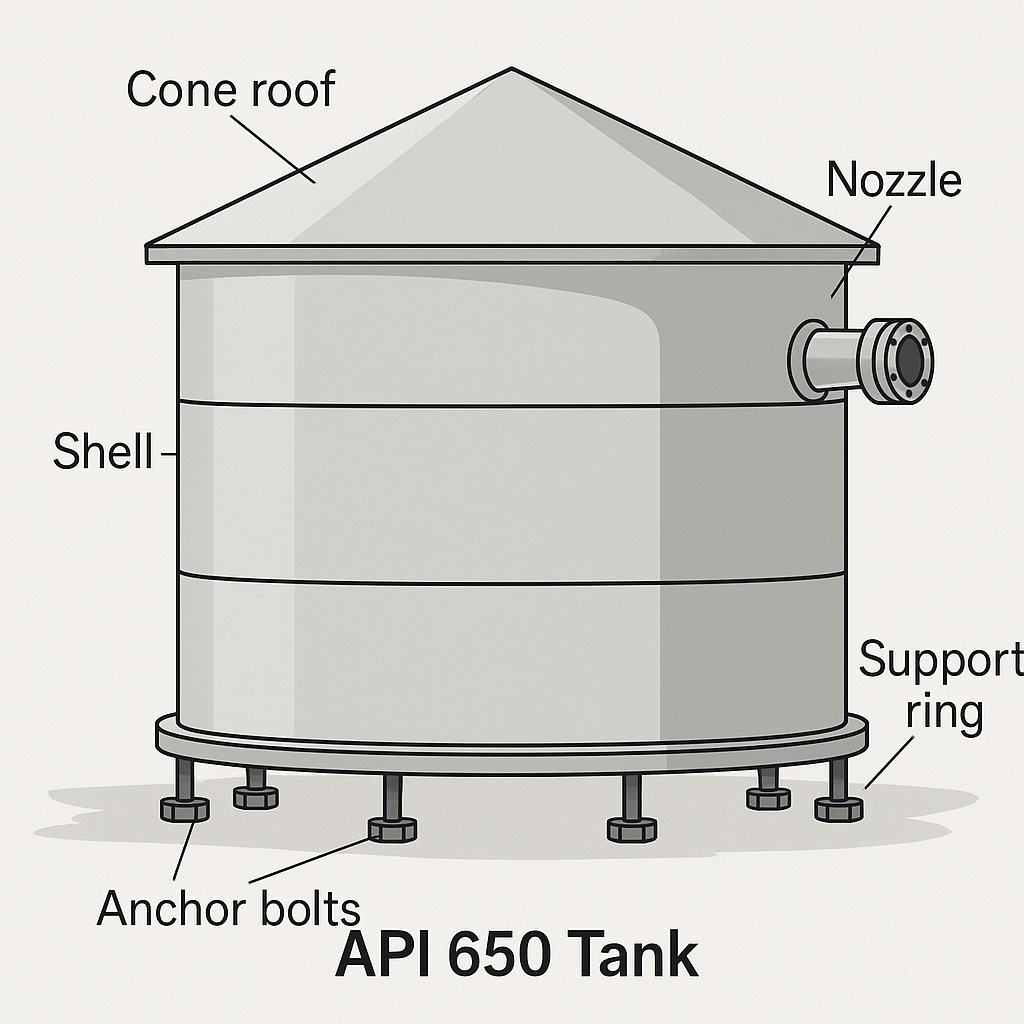

ASME® API 650 Tank Calculations: Engineering Atmospheric Storage with Confidence

API 650 is the industry standard for the design and construction of large, field-erected storage tanks that operate at atmospheric pressure or low internal pressures (not exceeding 2.5 psig). These tanks are essential for safely storing crude oil, petroleum products, water, chemicals, and other liquids across a wide range of industries.

Behind every safe and compliant tank is a set of precise API 650 tank calculations that dictate shell thickness, roof design, nozzle reinforcement, and anchoring—all in accordance with engineering codes, wind and seismic loads, and fluid characteristics.

Scope and Application of API 650

API 650 covers:

- Welded, carbon steel tanks

- Above-ground vertical cylindrical tanks

- Operating pressures ≤ 2.5 psig

- Typical sizes ranging from 10,000 to several million gallons

These tanks are not pressurized vessels; they are designed to safely contain fluids at ambient temperatures with internal pressure close to atmospheric.

Pictured above: visual diagram of an API 650 tank (e.g., cone roof, shell, nozzle, anchor bolts)

Key Elements of API 650 Tank Calculations

- Shell Thickness and Hydrostatic Pressure

Shell thickness is calculated based on:

- The height of liquid and specific gravity

- Corrosion allowance

- Weld joint efficiency (typically 1.0 for full-penetration welds)

- Minimum thickness values for material grade

Formulas in Section 3 and Appendix E provide the baseline for hydrostatic head pressure design.

- Roof Design

API 650 tanks may include:

- Self-supporting cone roofs

- Supported cone roofs with rafters

- Floating roofs (for volatile liquid storage)

- Domed or umbrella-type roofs

Calculations verify:

- Plate thickness and slope

- Rafter or girder spacing

- Uplift resistance under wind and vacuum

- Wind and Seismic Loading

Tanks must withstand environmental loads according to site-specific conditions. API 650 incorporates:

- Wind loading from ASCE 7

- Seismic design using site class, soil conditions, and tank dimensions

- Uplift, overturning, and sloshing evaluations

- Nozzle and Manway Reinforcement

Openings require careful stress analysis. Calculations cover:

- Reinforcement area equivalency

- Nozzle neck and repad thickness

- Stress limits under internal and external pressure

- Anchorage and Bottom Design

If the tank is subject to uplift or seismic overturning, anchorage calculations ensure:

- Proper sizing and spacing of anchor bolts

- Base plate thickness and grout considerations

- Use of anchorage rings or anchor chairs (as per Appendix E)

API 650 Optional Appendices for Advanced Service

- Appendix E: Seismic design

- Appendix F: Design for small internal pressures

- Appendix P: External pressure from vacuum

- Appendix M: Tanks built from stainless steel

- Appendix S: Shell buckling from wind or vacuum

These appendices support specialized applications and service conditions, helping engineers tailor tanks to site-specific challenges.

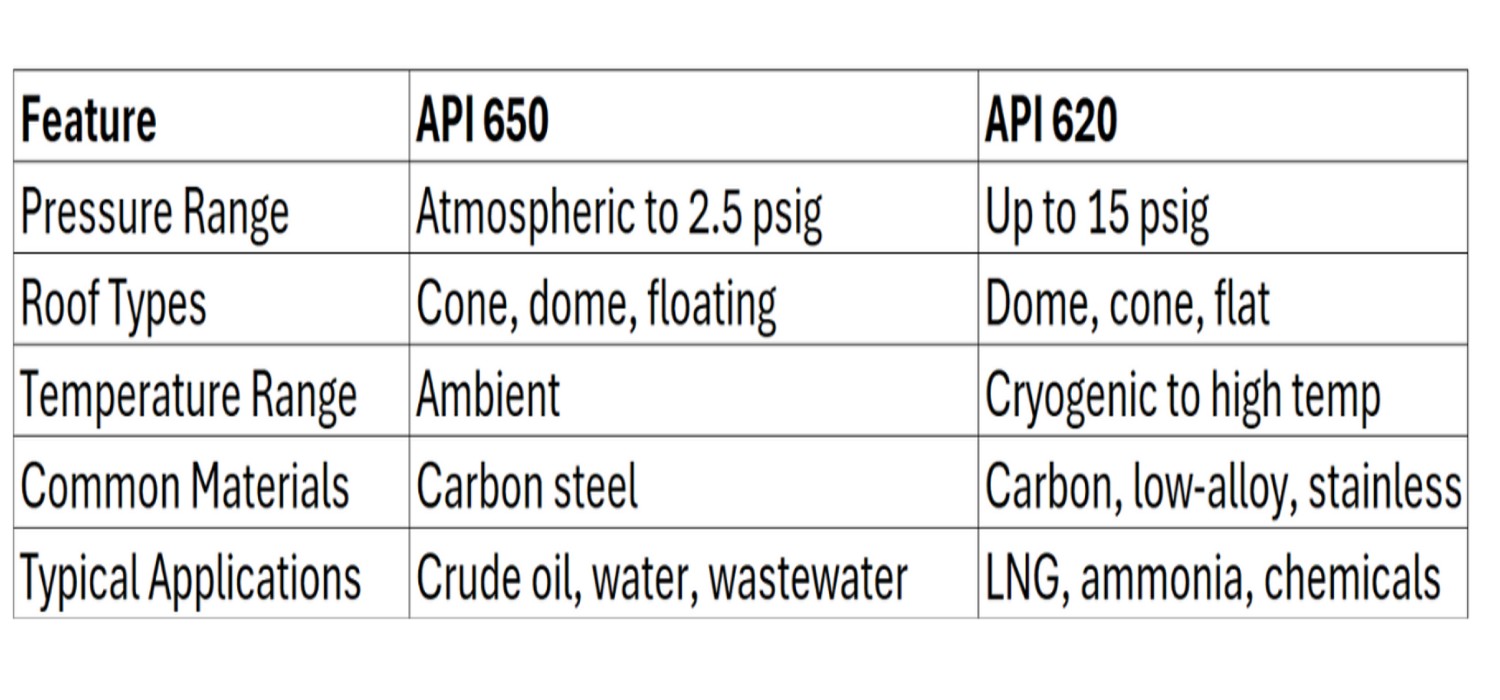

API 650 vs. API 620: Which Standard to Use?

Common Applications of API 650 Tanks

- Crude oil storage terminals

- Fire water storage

- Process water or wastewater

- Diesel and jet fuel storage

- Agricultural liquid storage

These tanks are built for volume, durability, and ease of fabrication—making them the global standard for large-scale atmospheric tanks.