A Necessary Component of Natural Gas Processing

BTEX Condenser Units are essential components of natural gas dehydration processes. These units are designed to capture and condense harmful volatile organic compounds (VOCs), specifically Benzene, Toluene, Ethylbenzene, and Xylene (BTEX), which are naturally occurring in crude oil and natural gas.

Pictured above: BTEX Condenser Unit

Why are BTEX Condenser Units Important?

Environmental Protection: By capturing and condensing BTEX, these units prevent harmful emissions from entering the atmosphere.

Worker Safety: BTEX compounds pose significant health risks, including cancer. By removing these compounds, producers can safeguard the health of their workers.

Regulatory Compliance: Many regulatory agencies require the control of VOC emissions, making BTEX Condenser Units a necessity for compliance.

How Do BTEX Condenser Units Work?

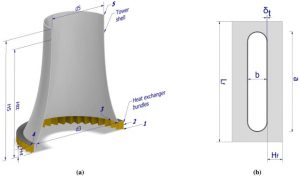

Steam Capture: The unit captures steam generated during the gas dehydration process.

Cooling and Condensation: The captured steam is cooled, causing it to condense into a liquid form.

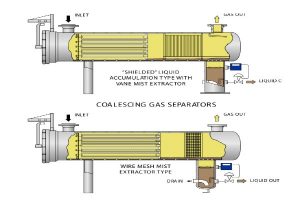

Liquid Separation: The condensed liquid is separated from non-condensable gases.

Disposal: The liquid is then collected and disposed of in an environmentally sound manner.

Gas Treatment: Non-condensable gases are either incinerated or vented through a catalytic converter to reduce emissions.

Key Considerations for BTEX Condenser Units:

Material Selection: Due to the corrosive nature of the condensed liquids, stainless steel is often used in the construction of these units.

Pressure and Flow Rate: Units must be designed to handle the specific pressure and flow rates of the process.

Maintenance: Regular maintenance is crucial to ensure optimal performance and to prevent equipment failures.

By effectively capturing and removing BTEX, these units play a vital role in protecting both the environment and human health.