Centrifugal Separators: Harnessing Centrifugal Force for Efficient Separation

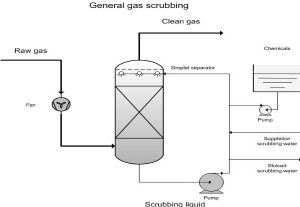

Centrifugal separators are a type of mechanical separator that utilizes centrifugal force to separate particles from a fluid. They are widely used in various industries, including oil and gas, chemical processing, and wastewater treatment.

How Centrifugal Separators Work

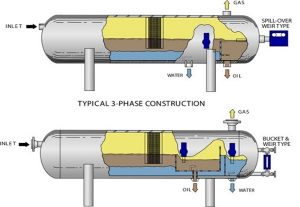

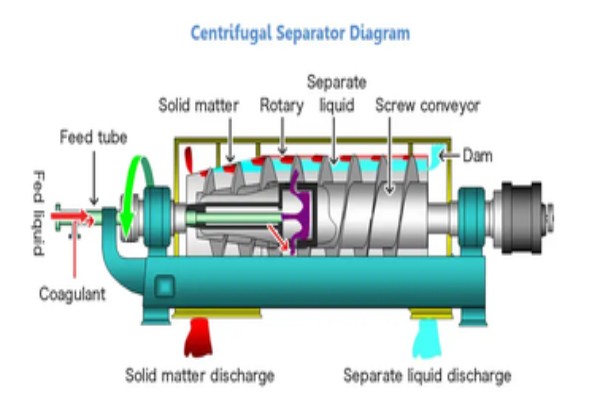

A centrifugal separator typically consists of a rotating bowl or drum. The fluid mixture is introduced into the bowl, and as the bowl spins, the centrifugal force causes the denser particles to move towards the outer wall, while the lighter fluid remains near the center. The separated components can then be continuously or periodically removed.

Pictured above: Centrifugal Separators

Types of Centrifugal Separators

Solid Bowl Centrifuges:

- Disc Stack Centrifuges: These separators use a stack of discs to increase the separation surface area.

- Solid Bowl Decanter Centrifuges: These separators continuously discharge solids from the bowl.

Liquid-Liquid Separators:

- Tubular Bowl Centrifuges: These separators are used to separate two immiscible liquids with different densities.

- Disc Stack Separators: These separators can also be used for liquid-liquid separations.

Design Considerations for Centrifugal Separators

The design of a centrifugal separator involves several key factors:

- Bowl Geometry: The shape and size of the bowl influence the separation efficiency and capacity.

- Rotation Speed: The rotational speed determines the centrifugal force and separation efficiency.

- Feed Inlet Design: The inlet design should ensure uniform distribution of the feed mixture.

- Discharge System: The discharge system should be designed to efficiently remove the separated phases.

- Material Selection: The materials of construction should be selected based on the fluid properties and operating conditions.

- Balancing: Proper balancing is essential to minimize vibration and ensure smooth operation.

Design Data for Centrifugal Separators

The design data for centrifugal separators can vary significantly depending on the specific application and the type of separator. However, some key parameters include:

- Bowl Diameter and Height: These dimensions determine the capacity of the separator.

- Rotation Speed: The rotational speed is typically expressed in revolutions per minute (RPM).

- Flow Rate: The maximum flow rate that the separator can handle.

- Separation Factor: A measure of the separator’s ability to separate particles of different sizes and densities.

- Power Consumption: The power required to drive the separator.

- Maintenance Requirements: The frequency and complexity of maintenance tasks.

Centrifugal separators are versatile and efficient tools for separating a wide range of mixtures. By understanding the principles of operation and the key design considerations, engineers can optimize the performance of these separators and achieve high levels of separation efficiency.