What Are The Conditions Affecting the Design and Operation of Gas Dehydrators?

Equipment size and amount of water removed by a glycol dehydrator are affected by the following variables

- Inlet gas temperature

- Inlet gas pressure

- Gas flow rate

- Glycol inlet temperature to the absorber (or contactor, as you prefer)

- Number of trays in the contactor

- Glycol concentration entering the absorber (or contactor, as you prefer)

- Glycol circulation rate

These variables must be controlled if the desired water content reduction is to be achieved.

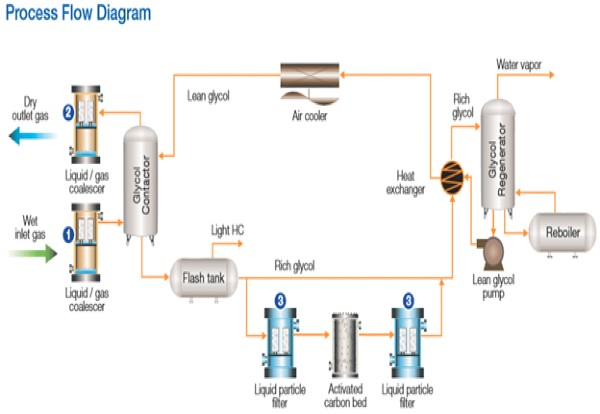

Picture showing the Dehydration Unit Process Flow Diagram

Inlet Gas Temperature

The inlet gas temperature profoundly affects the water content of the gas entering the contactor. If the gas temperature increases while still in contact with free water, the gas will absorb additional water vapor.

If the inlet gas temperature is above the ambient temperature, another operation problem can be encountered. Contactors operating with rich gas at temperatures above the ambient can have condensation of the heavier hydrocarbon fractions on the wall of the contactor. These will accumulate in the system and contaminate the glycol unless provision is made for their removal.

When line heaters are used to heat the gas stream to prevent hydrate formation ahead of the dehydrator during cold weather, the inlet gas temperature to the dehydrator should not be allowed to rise excessively.

However, the inlet temperature should be maintained above 60oF. At gas inlet temperatures below 60oF, the glycol will be cooled sufficiently so that the increase in viscosity of the glycol will result in low efficiency in the gas-glycol contact and increase the tendency of the glycol to foam. Foaming results in a significant reduction of dehydration of the gas stream and loss of glycol.

Inlet Gas Pressure

Normally, the inlet gas pressure will not fluctuate enough from the design conditions to be a critical factor. However, if the inlet gas pressure is very low, the water content of the gas will be very high.

In the pressure range of 125 psig to 250 psig, the quantity of water to be absorbed by the circulating glycol is quite large and consideration must be given to the heat of reaction or absorption.

Normally, the inlet gas pressure will not fluctuate enough from the design conditions to be a critical factor.

However, if the inlet gas pressure is very low, the water content of the gas will be very high. In the pressure range of 125 psig to 250 psig, the quantity of water to be absorbed by the circulating glycol is quite large and consideration must be given to the heat of reaction or absorption.

This can raise the glycol temperature on the contactor trays several degrees above the gas temperature.

Units that are operated below the design pressure cannot produce the designed dew point depression without increasing the glycol circulation rate in terms of gallons of glycol circulated per pound of water vapor removed and/or the lean glycol concentration.

In some cases, sufficient circulation and reboiler capacity may be available to increase the circulation and/or lean glycol concentration to enable a given unit to reach the desired outlet dew point temperature. It will be necessary that the gas rate be reduced to keep the actual gas velocity in the proper range through the contactor. Each case will have to be reviewed by the operator in charge.

Gas Flow Rate

Units are designed to operate efficiently at a specified range in gas rate.

Below this range, there will be some loss of efficiency in terms of increased outlet dew point and reduced dew point depression.

Above this range, the unit will not only lose dehydration efficiency but will also experience excessive glycol losses.

Also, at flow rates above the normal maximum, the re-concentrator will become overloaded, resulting in insufficient glycol reconcentration and the outlet gas dew point will again increase.

The flow rate must be relatively constant. Rapid surges or changes in flow rate can cause a loss of seal in the contactor’s tray downcomers.

This will cause not only loss of dehydration but also excessive glycol loss as the gas will lift the glycol out of the contactor. Once the seal on the downcomers is lost, the only way it can be re-established is to shut in the contactor and put it back online gradually.

Glycol Inlet Temperature to the Contactor

The temperature of the glycol entering the contactor has a significant effect on the gas dew point depression and should be held to within 10oF above the inlet gas temperature. Higher glycol losses and higher outlet gas dew points occur when the lean glycol enters the contactor at a temperature more than 10oF above the gas temperature.

Number of Trays in the Contactor

Most manufacturers use five contact trays (bubble cap, valve, or sieve type) in their standard units. Our standard units typically have six or eight trays in the contactor to achieve a better balance between the contactor and regenerator capacities and greater flexibility in operation.

For a given glycol circulation rate, higher dew point depressions are obtained as additional trays (or equivalent length of packing) are added to the contactor. The increase in unit cost for additional trays for a given dehydration problem is not as much as that resulting from increased glycol reconcentration and/or circulating capacity which would alternately be required. High dew point depression units require seven or more trays. Rarely does the number of contactor trays exceed ten.

In contactors that are too small to allow installation of trays, a “packing” is used to provide the contact between the wet gas and the lean glycol. “Packing” is a metal, ceramic, or plastic object that is designed to furnish a large surface area. The glycol spreads over these surfaces in a thin film. Contact is affected as the gas is passed over the glycol-wetted surfaces.

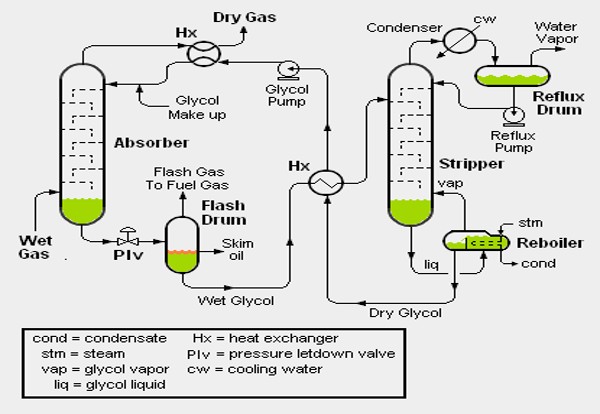

Picture showing the trays inside the Absorber (Contactor)

Glycol Concentration Entering the Contactor

The one single change that can be made in a glycol system, which will produce the largest effect on dew point depression, is the degree of glycol reconcentration (usually stated as a percent of purity), which is obtainable by the re-concentrator.

For example, assuming a contactor with 6 trays and a glycol rate of 3 gals. Per lb. of water vapor in the inlet gas, the maximum dew point depression obtainable with 98.5% triethylene glycol is 67oF. Changing the concentration to 99.1%, the dew point depression would be 75oF. If stripping gas is used and the concentration increased to 99.9%, the maximum dew point depression is 95oF.

In the reboiler where the glycol is heated and then cooled for storage, the concentration to 99.1% can be achieved simply by raising the re-concentrator temperature to 400oF. In these units, it is necessary to use one of the stripping gas methods to achieve a concentration above 99.1%.

Glycol Circulation Rate

The dew point depression with a given number of trays and a specific glycol concentration can be increased by increasing the circulation rate.

With 98.5% triethylene glycol, six trays, and 100oF contact temperature, the dew point depression can be increased from 61oF to 69oF by changing the circulation rate from 2 gal per lb. of water removed to a 4 gal per lb. of water removed.

However, care must be exercised when increasing the glycol rate as the re-concentrator capacity can easily be exceeded.

Secondly, too much circulation can cause the temperature of lean glycol entering the absorber to increase with a subsequent increase in overhead glycol loss.

This occurs because the capacity of the glycol-gas heat exchanger has been exceeded.

Higher circulation rates will also increase pump maintenance requirements. The circulation rates should also be as low as possible and still produce the desired dew point depression.

A circulation ratio of 2 gals per lb. of water vapor removed is considered to be the minimum required to assure adequate glycol flow across the trays.

Conditions Affecting Glycol Losses

Contactor towers operating at gas rates more than manufacturer’s recommended maximum rates will show higher glycol losses than towers operating below the maximum recommended ratings.

Where dehydrated gas from a glycol unit is used for a gas lift system, care must be used in both sizing and operating the glycol unit because of the unsteady gas rate that exists in this type of service.

It is recommended that a backpressure valve be installed on the gas outlet from the contactor operating on a gas lift system.

If this is not done, then a valve downstream of the contactor should be pinched to help even out the flow through the unit and minimize the overloading of the contactor.

Momentary overloading of the glycol contactor can break the downcomer seals in a tray-type tower and cause excessive loss of glycol.

Contactor towers operating at temperatures above 100°F will show greater glycol losses than those operating below 100°F.

Contactor towers operating at a pressure below 800 psi will show greater glycol losses than those operating above 800 psi.

Running the glycol pumps at the maximum operating speed always will cause greater glycol losses when the gas flow rate is reduced than when the pump speed is reduced in proportion to the gas flow rate.

Abnormally high losses will be encountered when the pumps are operated at maximum rates and the gas flow is reduced to a very low rate.

Operation at very low gas inlet temperatures (60°F or less) can be expected to cause excessive glycol losses due to the foaming of the glycol.