Cyclone Separators: A Centrifugal Force Solution

Cyclone separators are a type of mechanical separator that uses centrifugal force to separate solid particles from a gas or liquid stream. They are widely used in various industries, including mining, chemical processing, and environmental engineering.

How Cyclone Separators Work

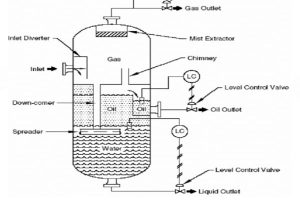

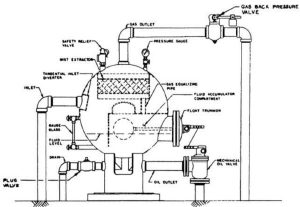

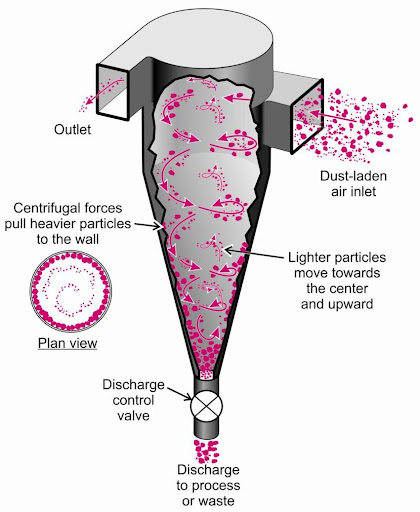

A cyclone separator typically consists of a cylindrical or conical vessel with a tangential inlet and outlet ports. When a gas or liquid mixture enters the cyclone tangentially, it spirals downward due to centrifugal force. The heavier particles are forced to the outer wall and fall into a collection hopper, while the lighter fluid flows out the top.

Pictured above: Cyclone Separator

Types of Cyclone Separators

High-Efficiency Cyclones: These cyclones have a high separation efficiency for fine particles. They typically have a smaller diameter and a higher gas velocity.

Low-Efficiency Cyclones: These cyclones have a lower separation efficiency but a higher capacity. They are often used as pre-cleaners before high-efficiency cyclones.

Design Considerations for Cyclone Separators

The design of a cyclone separator involves several key factors:

- Cyclone Diameter: The diameter of the cyclone affects the separation efficiency and pressure drop.

- Cyclone Height: The height of the cyclone influences the residence time of the particles.

- Inlet Velocity: The inlet velocity affects the centrifugal force and separation efficiency.

- Vortex Finder Diameter: The diameter of the vortex finder controls the flow of gas out of the cyclone.

- Cone Angle: The angle of the cone affects the separation efficiency.

- Material Selection: The material of construction should be selected based on the fluid properties, temperature, and pressure.

Design Data for Cyclone Separators

The design data for cyclone separators can vary depending on the specific application and the desired separation efficiency. However, some key parameters include:

- Particle Size: The minimum particle size that can be effectively separated.

- Separation Efficiency: The percentage of particles removed from the gas stream.

- Pressure Drop: The pressure drop across the cyclone.

- Flow Rate: The volumetric flow rate of the gas or liquid mixture.

By carefully considering these design factors, engineers can select and design cyclone separators that meet the specific needs of a particular application.

Key Applications of Cyclone Separators:

- Dust Collection: Removing dust particles from gas streams in industrial processes.

- Gas Cleaning: Separating solid particles from gas streams in power plants and chemical plants.

- Liquid-Solid Separation: Separating solid particles from liquid streams in water treatment and mineral processing.

Cyclone separators are a simple and effective solution for separating particles from gas and liquid streams. By understanding the key design parameters and selecting the appropriate cyclone design, engineers can optimize the performance of these devices.