Separator Demister Pad

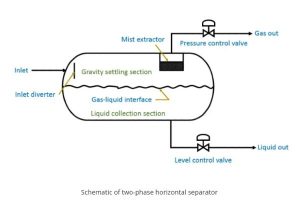

A demister is also known as a demister pad, mist pad, wire mesh demister, mesh mist eliminator, catching mist, and mist eliminator. It is a device often fitted to vapor–liquid separator vessels to enhance the removal of liquid droplets entrained in a vapor stream.

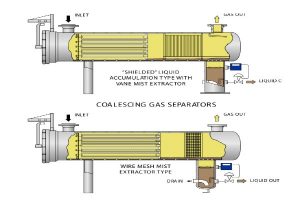

Demisters may be a mesh-type coalescer, vane pack or other structure intended to aggregate the mist into droplets that are heavy enough to separate from the vapor stream.

Demisters can reduce the residence time required to separate a given liquid droplet size by reducing the volume and associated cost of separator equipment. Demisters are often used where vapor quality is important in regard to, entrained liquids, particularly where separator equipment costs are high (e.g., high-pressure systems) or where space or weight savings are advantageous.

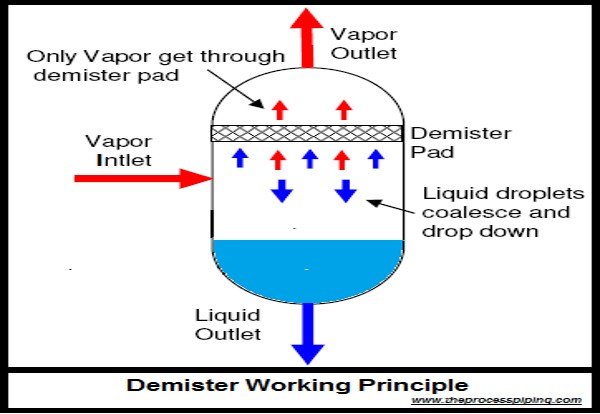

Pictured above: Illustration of how a Demister works

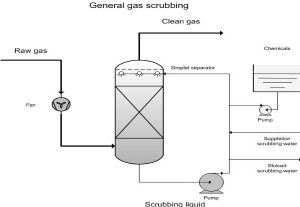

A demister is mainly used in process piping systems like;

- Absorption columns

- Distillation columns

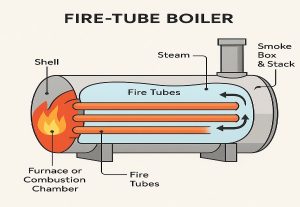

- Steam Boilers

- Gas and Air scrubbers

- Oil Mist Separation

- Effluent gas treatment in Sulphuric Acid Factories.

- Vacuum Towers and Drying Towers

- Knockout Drums

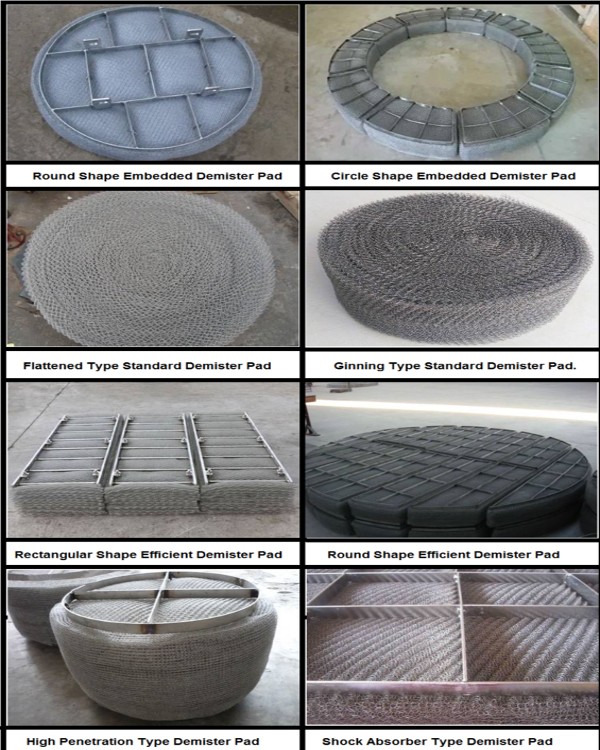

Types of Demisters Pads

Demister pad forms have four categories: standard type, efficient type, high penetration type, and shock absorber type. Below is the image of all four types being used in the process piping industry.

Pictured above: Types of Demisters Pads – four categories: standard type, efficient type, high penetration type, and shock absorber type

Demister Working Principle

When the gaseous or vapor stream with mist rises at a constant speed and passes through the demister, the mist will collide with the demister mesh filament and attach to the surface of the filament due to the inertia effect. The mist will diffuse on the filament surface and liquid droplets will start forming. The liquid droplets will grow bigger and isolate from the filament until the droplet’s gravity exceeds the gas rising force and liquid surface tension force. Thus, the bigger liquid droplets drop down in the pool of liquid below. The gaseous or vapor stream is not affected by the obstruction in the path and escapes through the top vapor outlet.

When installing the demister, the demister pad must fit tightly to the wall of the column or vessel, or tower to prevent any gas from leaking from the contact surface. When properly designed, demister pads can give an efficiency of up to 99.9% with minimal pressure drop.

Advantages of Demister

demister is a necessity to be used where the liquid in a gaseous or vapor stream is not acceptable. For example – compressor suction lines. Separation of mist from gaseous or vapor stream can improve the operating condition, optimize process indicators, reduce corrosion of the equipment, extend equipment life, increase the amount of processing and recovery of valuable materials, protect the environment, and decrease air pollution. Demister also produces high-quality condensate suitable for use in a boiler’s feed water.

Must have Featured in a Demister

- Simple structure

- Lightweight

- High porosity

- Cause less pressure drops

- Large surface area

- High mist separating efficiency

- Easy to install, operate and maintain

- Easily tailor-made to suit most vessel shapes and sizes

- Durable and long service life

- Corrosion resistance

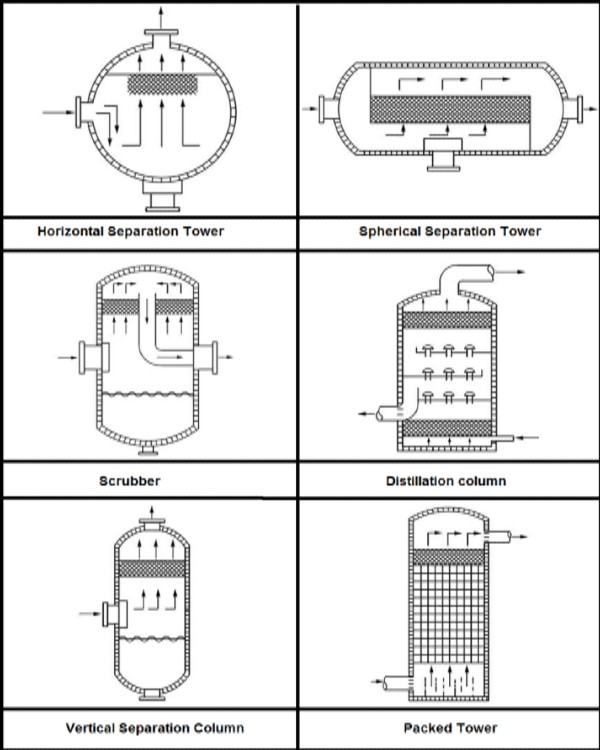

Demister Installations in Columns / Vessels / Towers

Demister can be installed in columns or vessels or towers in various positions depending upon the shape, vapor inlet nozzle location, vapor outlet nozzle location, liquid outlet nozzle location, and process applications. Below is the figure showing such a few installation types.

Pictured above: Illustration of where a Demister is installed in Columns/ Vessels / Towers

Maintenance

After using it for a long duration, the demister pad will clog or be prone to flooding and the pressure drop will increase because of the particles in the gas blocking the demister pad mesh openings. So, maintenance of the demister pad is required regularly. In maintenance, the demister pad is cleaned thoroughly for the opening of all blockages.