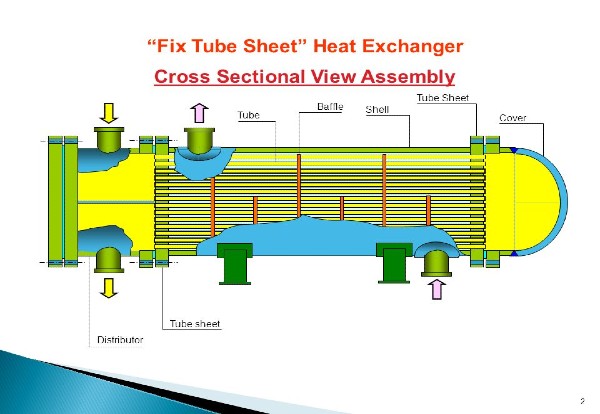

Fixed Tube Sheet Heat Exchangers: A Reliable Choice for High-Pressure Applications

Fixed tube sheet heat exchangers are a type of shell and tube heat exchanger where both tube sheets are fixed to the shell. This design is suitable for high-pressure applications and offers several advantages.

Pictured above: Fixed Tube Sheet Heat Exchanger

Advantages of Fixed Tube Sheet Heat Exchangers:

- High-Pressure Capability: The fixed tube sheet design allows for high-pressure applications.

- Compact Design: The fixed tube sheet design can be more compact than other types of heat exchangers.

- Reliable Operation: The rigid structure of the fixed tube sheet design ensures reliable operation.

Disadvantages of Fixed Tube Sheet Heat Exchangers:

- Thermal Expansion and Contraction: The fixed tube sheets can be susceptible to thermal stress, especially in high-temperature applications.

- Maintenance Challenges: Cleaning and replacing tubes can be more difficult than with other types of heat exchangers.

Key Considerations for Fixed Tube Sheet Heat Exchanger Design and Selection:

- Tube Material: The tube material should be selected based on the fluid compatibility and temperature requirements.

- Tube Pitch: The spacing between the tubes can affect the heat transfer performance.

- Baffle Design: The baffle design can influence the flow pattern and heat transfer efficiency.

- Tube Sheet Thickness: The tube sheet thickness must be sufficient to withstand the operating pressure.

- Expansion Joint Design: If necessary, expansion joints can be incorporated to accommodate thermal expansion and contraction.

Fixed tube sheet heat exchangers are a reliable and efficient solution for high-pressure applications. Their simple design and robust construction make them a popular choice in many industries.

By carefully considering these factors, engineers can select and design fixed tube sheet heat exchangers that meet the specific needs of a particular application.