Floating Head Heat Exchangers: A Flexible Solution for High-Pressure Applications

Floating head heat exchangers are a type of shell and tube heat exchanger designed to accommodate thermal expansion and contraction of the tube bundle. This design is particularly useful for high-pressure applications where significant temperature differences can occur between the shell-side and tube-side fluids.

How Floating Head Heat Exchangers Work

In a floating head heat exchanger, one tube sheet is fixed to the shell, while the other is free to move. This allows the tube bundle to expand and contract without putting undue stress on the shell and tubes.

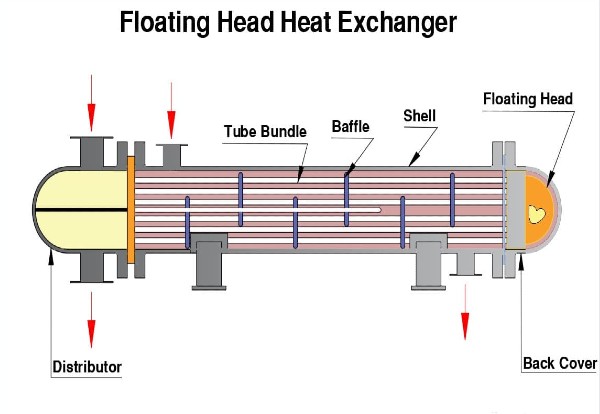

Pictured above: Floating Head Heat Exchanger

Key Components of a Floating Head Heat Exchanger:

- Shell: The outer cylindrical casing that encloses the tube bundle.

- Tube Bundle: A bundle of tubes arranged in a specific pattern within the shell.

- Fixed Tube Sheet: The tube sheet that is fixed to the shell.

- Floating Head: The tube sheet that is free to move within the shell.

- Expansion Joint: A flexible joint that allows for thermal expansion and contraction of the tube bundle.

- Baffles: Plates or grids placed inside the shell to direct the flow of the shell-side fluid and improve heat transfer efficiency.

- Nozzles: Connections for the inlet and outlet of both fluids.

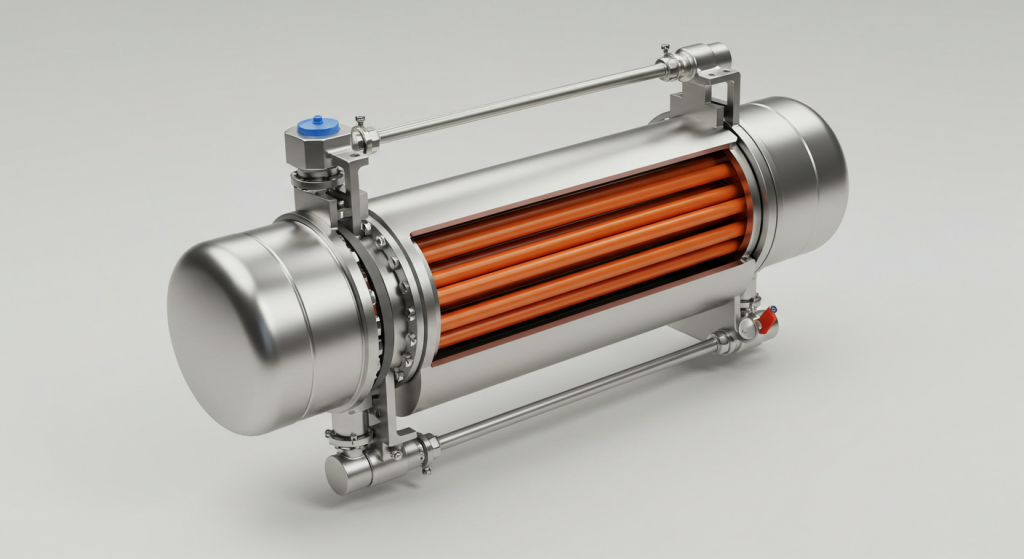

Pictured above: Floating Head Heat Exchanger

Advantages of Floating Head Heat Exchangers:

- Accommodates Thermal Expansion: The floating head design allows for significant thermal expansion and contraction, reducing the risk of tube failures.

- High-Pressure Capability: Suitable for high-pressure applications.

- Versatility: Can handle a wide range of fluids and temperature differences.

- Reliable Operation: Proven technology with a long history of reliable performance.

Disadvantages of Floating Head Heat Exchangers:

- Complex Design: More complex to design and manufacture than fixed tube sheet heat exchangers.

- Higher Cost: Typically more expensive than fixed tube sheet heat exchangers.

Floating head heat exchangers are a reliable and efficient solution for high-pressure applications. Their ability to accommodate thermal expansion and contraction makes them a valuable tool in many industries.

By understanding the principles of operation and the key design considerations, engineers can select and design floating head heat exchangers that meet the specific needs of a particular application.