What is a Gas Scrubber?

Stringent regulations on air pollution are being implemented globally, urging companies to adopt necessary measures. Gas scrubbers are legally mandated in industries where employees are exposed to potentially contaminated gases, making them a widely employed method for pollution control.

When effectively utilized, a gas scrubber can achieve remarkably high efficiency in removing harmful gas particles. Consequently, the emissions released into the surrounding air pose no threat to the environment.

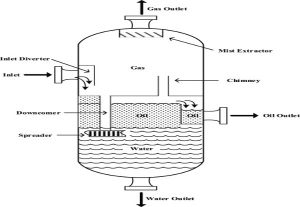

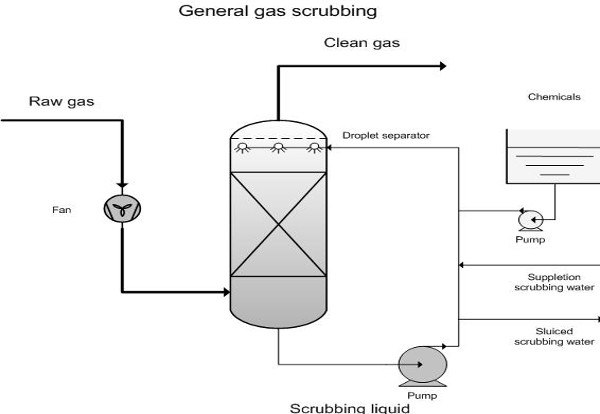

A gas scrubber serves as an essential purification system designed to eliminate detrimental components present in industrial air or waste gas streams. The scrubber does not take the place of a production separator but is usually installed in a pipeline after the gas stream has been through production separators and the gas has been transported some distance. Depending on the to-be-removed component, residual emission, scrubbing liquid, and the type of application, yields in excess of 99% can be realized.

Pictured above: Diagram of how a Gas Scrubber works

These scrubbers are normally vertical units, but horizontal units are available for specific applications. Its primary purpose is to counteract the effects of noxious fumes or unpleasant odors caused by these gas particles, ensuring their elimination before the gases are released into the atmosphere. All scrubbers operate in the same manner as vertical and horizontal two-phase separators.

Two-phase separators are designed to handle gas streams with relatively light liquid loads and in applications where it is essential that liquid particles be removed from the gas stream.

Scrubbers have a broad range of applications in:

- Chemicals industry

- Waste incineration installations

- Pharmaceutical industry

- Storage and transfer of chemicals

- Surface treatment

In certain instances, a gas scrubber can also facilitate the recovery of specific raw materials after the purification process. Notably, the versatility of gas scrubbers extends to various sectors, including the chemical industry, pharmaceutical industry, and surface treatment.

Functioning Mechanism of a Gas Scubber

Typical applications are as follows:

- Upstream of units using either wet or dry desiccants which would lose efficiency, be damaged, or be destroyed if contaminated with liquid hydrocarbon.

- Downstream of equipment, which causes liquids to condense from a gas stream.

- Upstream mechanical equipment such as compressors, which would be damaged, destroyed, or rendered ineffective by free liquid.

Typical applications are as follows:

- Upstream of units using either wet or dry desiccants which would lose efficiency, be damaged, or be destroyed if contaminated with liquid hydrocarbon.

- Downstream of equipment, which causes liquids to condense from a gas stream.

- Upstream mechanical equipment such as compressors, which would be damaged, destroyed, or rendered ineffective by free liquid.

The flow direction of gas and liquid

Scrubbers can be distinguished in terms of the flow direction of the gas in relation to the liquid. A distinction is made between

- counter-flow

- co-current

- crossflow scrubbers

Counter-Flow Scrubbing

In counter-flow scrubbing the scrubbing liquid and the to-be-cleaned gas flow in opposite directions. The main advantage of counter-flow scrubbing is that the cleaner the gas becomes, the lower the pollutant concentration in the scrubbing liquid becomes – whereby the driving force is maintained throughout the column. This type of scrubber is, for example, particularly suited to irregular and peak emissions. The counter-flow setup allows high-concentration peaks to be better dealt with.

Co-Current Scrubbers

In co-current scrubbers, the gas and liquid stream move in the same direction. They are less effective than counter-flow scrubbers. However, the advantage they offer is that they are suited to high gas and liquid loads. Co-current scrubbers have a more compact construction and are normally considered when limited space is available and a lower yield is acceptable. Further, they are effective as an initial scrubbing stage for a counter-flow scrubber, for example, when the gas flow needs to be cooled or partly separated.

Cross-Current Scrubbers

In cross-current scrubbers, the gas, and the liquid move across one another. For vapor-like components, the liquid will normally flow in a downward direction and gases will flow horizontally. In dust scrubbing, the sprayers will be horizontal to the gas flow. This type of scrubber is more compact than a counter-current scrubber, if one works with a multi-stage set-up, and uses less electricity.

A cross-current scrubber is suited to emissions with known maximum concentrations, thus allowing it to be dimensioned appropriately. In case of very high concentration peaks, for which the scrubber has not been dimensioned, the scrubbing liquid will be saturated before it reaches the bottom of the packing. This means that a part of the air will not be (fully) treated, with yield loss as a result.

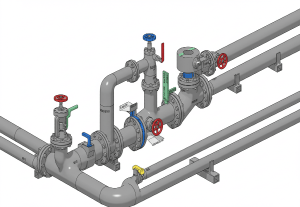

Pictured above: Gas Scrubber In-Service

Gas scrubber with or without built-in device:

Gas scrubbers can also be distinguished by the set-up of the wash section, e.g., with or without a built-in device. The built-in device could be a bulk or structured packing or construction with plates or a rotating disk. The main layout can be further broken down as follows:

Gas scrubbers without built-in device:

Spray towers: In spray towers the water is dispersed in fine droplets, normally via sprayers at the top of the scrubber, while the gas is fed from underneath – thus in counter-current. Set-up is also possible in co-current or cross-current formats. Can also be used as a dust scrubber.

Jet scrubbers: In a jet scrubber, the gas and scrubbing liquid are brought into contact with one another in a co-current direction, in accordance with the workings of a water jet pump. In the wash section, the jet breaks down into droplets, which creates a large phase interface. In the next area, the gas and the liquid are separated.

Venturi scrubber: A venturi scrubber consists of a converging section, a throat (the narrowest part of the venturi tube) and a diffuser. The gas flows through the venturi tube and reaches top speed in the throat section. Thereafter, the gas passes into the diffuser where the speed of the gas drops once again. The liquid is added to the gas flow either in the throat section or prior to it. Intensive mixing takes place between the gas and the liquid in the throat section of the venturi tube. Due to the high speed realized by the gas and liquid, the water is broken down into fine water droplets. Can also be used as a dust scrubber.

Gas scrubbers with built-in device:

Plate column: A plate column is a column which is divided into segments by perforated plates. The perforations have been designed in a way that forces the to-be-cleaned gas to bubble through a sealed fluid layer on the plates, which is where absorption takes place.

Packed columns: Scrubbers with packed columns are filled with structured or unstructured packing material. This material has a high specific surface area, which means a large phase interface is created between the gas and the liquid. The scrubbing liquid flows downwards in a thin film over the packing material, while the gas flows upwards through the remaining free space. In scrubbers with packed columns, the liquid and the gas do not disperse into one another.

Rotation scrubber: In rotation scrubbers the scrubbing liquid is, via a fast-rotating spray, broken down into small droplets, whereby a large contact area is created between droplets and gas. As a result of the rotating sprayer, dust particles are forced to the sides of the scrubber and separated. Rotation scrubbers are primarily used as dust scrubbers.

Ionisation scrubbers: These are a modified form of wet E filters. They are scrubbers with a built-in ionisation phase.

The compatibility of the various scrubber types is determined by the properties of the to-be-cleaned gas.

If it contains a lot of solid particles or other components that could lead to cake-forming and blockage, then a scrubber will be selected which is less sensitive to these factors – such a various scrubbers without built-in devices.

Another possibility is to install a multi-stage scrubbing system, where the various stages are designed to remove different components. Plate columns are primarily used in the chemicals industry. They are rarely used for environmental purposes due to the high investment costs.

Another possibility is to install a multi-stage scrubbing system, where the various stages are designed to remove different components. Plate columns are primarily used in the chemicals industry. They are rarely used for environmental purposes due to the high investment costs.