What is a Glycol Dehydration Unit?

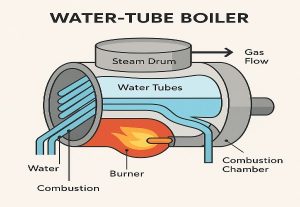

Glycol dehydration processes utilize glycol solvents to remove water from wet natural gas to meet pipeline quality specifications or condition the gas for condensate liquids removal. The wet gas is contacted with lean glycol in the contactor tower. The rich glycol then flows to a regenerator, where heat separates the glycol and the water, regenerating the glycol for re-use. The water vapor exits the top of the regenerator to the atmosphere while the lean glycol is recirculated back to the contactor in a recirculating loop.

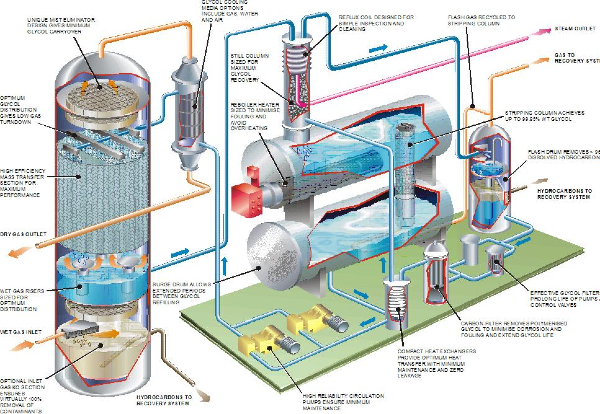

Pictured above: Glycol Dehydration System Unit

The glycol dehydrator of today consists of – an absorber (or contactor, if you prefer) for contacting the gas with highly concentrated triethylene or tetraethylene glycol, a glycol regenerator for reconcentrating the used glycol, glycol pumps for pumping the reconcentrated glycol to the top of the absorber, heat exchangers for fuel conservation and satisfaction of process requirements, and filters to keep the glycol clean and free from hydrocarbons and sediment. Improvements in reconcentrator designs, using stripping gas to reach higher regenerated glycol concentrations, have greatly extended this equipment’s range.

The largest number of these units is on single-well -applications, but many large-volume central plants have been installed in recent years. Practically all these units utilize triethylene glycol.

Tetraethylene glycol has been used on relatively few installations. Even though it is quite expensive, it offers some advantages over triethylene in certain special applications.

Operating conditions of a Glycol Dehydrator?

The actual operating conditions of a glycol dehydrator must fall within the range of limitations of the unit if it is to perform satisfactorily. The extent of water removal that can be obtained is determined by

- Inlet gas temperature

- Type of liquid absorbent used

- The concentration of the absorbent

- Circulation rate

- Number of trays in the absorber

- Inlet pressure

- Quantity of contaminants in the absorbent

Two terms used in natural gas dehydration should be explained before proceeding further; these are

- Dew Point Temperature

- Dew Point Depression

These two terms are quite important to the operator since they are used to describe the unit’s performance. For under-saturated streams, dew point temperatures are physically determined with special instruments. From this information the actual water content of the gas stream at the point analyzed can be determined. Moisture analyzers such as the Bureau of Mines’ unit, MECCO, DuPont, Panametrics, etc., have all been developed to determine a wellstream’s dew point temperature quickly and accurately.

These two terms are quite important to the operator since they are used to describe the unit’s performance. For under-saturated streams, dew point temperatures are physically determined with special instruments. From this information the actual water content of the gas stream at the point analyzed can be determined. Moisture analyzers such as the Bureau of Mines’ unit, MECCO, DuPont, Panametrics, etc., have all been developed to determine a wellstream’s dew point temperature quickly and accurately.

How It Works

The concentrated or “lean” triethylene glycol is continuously pumped to the top tray of the contactor tower where it flows across the tray and is intimately mixed with gas from the tray below, passing out through the slots in the bubble caps. The glycol spills over the edge of the down comer pipes and passes from the top tray to the next tray below where the process is repeated. This process is repeated for each tray until the glycol reaches the bottom of the tower.

The wet or “rich” glycol passes out of the tower, through a strainer, and then to the power side of the glycol pump. In the pumps shown, the rich glycol helps furnish the motive power for pumping the dry glycol to the contractor. The additional power required by the pump is furnished by gas from the contactor. The wet glycol with the expanded gas passes through a glycol-glycol heat exchanger, where it is preheated (by the hot, dry reconcentrated glycol) before entering the reboiler to be concentrated.

The reboiler drives off the water vapor through the still column to the atmosphere and the re-concentrated glycol flows over a weir into the storage compartment. The hot re-concentrated glycol passes out of the storage compartment through the glycol-glycol exchanger, then through a filter and to the glycol pump, where it is pumped through the gas-glycol exchanger to the top tray of the contactor tower. The glycol-glycol exchanger serves to cool the hot lean stream to protect the pump as well as to pre-heat the cool rich glycol for heat conservation as mentioned before. The gas-glycol heat exchanger further cools the lean glycol to improve dehydration efficiency and minimize glycol losses from the contactor.

“It is imperative that the gas entering the glycol contactor be free of entrained liquid and solid particles if the desired dew points are to be achieved.”

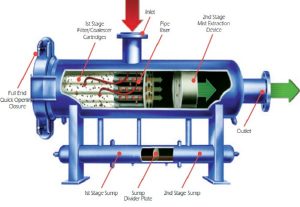

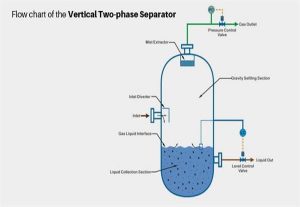

This means that the gas must already have passed through an adequately sized separator just prior to entering the contactor. Separators or Coalescer Scrubbers are recommended for installation ahead of glycol contactors. The alternate solution is to place an integral scrubber in the bottom section of the contactor tower.

The alternate solution is to place an integral scrubber in the bottom section of the contactor tower. The contactor shown here has an integral scrubber section. This offers savings in capital investment, simplified erection, foundations, and hook-ups. An integral scrubber might be included in standard dehydrators.

Pictured above: 3D TEG – Schematic of a standard TEG Glycol Dehydration Plant

The wet gas enters the scrubber section in the bottom of the contactor releasing its entrained liquid. The gas then passes upward through a wire mesh mist extractor, where the fine liquid particles are coalesced and removed, next through the chimney tray and then on through the contact trays. Liquids removed from the gas stream in the integral scrubber section are dumped by the liquid level controller to a distillate and/or water disposal.

Standard Absorber Accessories

- 6- Bubble cap trays on 24″ tray spacing (packed absorbers are also available).

- 1- Stainless steel knitted wire mesh mist extractor

- 1- Dial thermometer (0-250F) with thermowell

- 1- Pressure gauge with isolating valve

- 1- Relief valve

- 1- Galvanized outside ladder

- 1- Drain Valve

- 1- External gas-glycol heat exchanger

- Paint: One coat of standard primer and one coat of pallet tan

Standard Reconcentrator Accessories

- Set shop-installed energy-saving shell insulation with aluminum jacket and vapor barrier

- Removable firebox and removable stack

- Flame Arrestor

- Burner and pilot assembly

- Thermostat

- Thermometer (50-550F) with thermowell

- Fuel gas regulator

- Fuel gas pressure gauge

- Burner gas shut-off valve

- Pilot gas shut-off valve

- Insulated reservoir integral with the reboiler

- Liquid level gauge assembly

- Oil Skimmer connection

- Glycol filter with one extra element

- Glycol powered glycol pump

- High-pressure check valve on pump discharge

- High-pressure glycol strainer with blow-off valve

- External glycol-glycol heat exchanger

- Pump bleeder valve

- Packed still column

- Welded structural steel skid

- Set of piping for complete skid hookup including absorber and reboiler isolating valves

- Paint: One coat of standard primer and one coat of pallet tan

Optional Accessories

- Stack Arrestor

- Stack Down-draft Diverter

- Reflex liquid level gauge assembly for absorber

- Pilot flame-out safety shut-down w/ manual reset

- High reboiler temperature fuel gas shut-off w/ manual reset

- Spare glycol pump, manifolded for standby service

- Alternate glycol pumps (gas-powered and electrical powered)

- Automatic standby pump start-up

- Glycol-Gas-Hydrocarbon Separator installed in rich glycol line complete with standard accessories necessary to utilize flash gas as the normal fuel supply for reconcentrator.

- Oil skimmer sump on absorber

- Oil skimmer on reboiler still column

- Glycol pump shutdown alternate indirect heated reboilers (steam, hot oil, electric, and engine exhaust gases)

- Liquid section heating system special paints and coatings