Gravity Separators: A Simple Yet Effective Solution

Gravity separators are a fundamental type of separation equipment that leverages the principle of density difference to separate solid particles from liquids or different liquid phases from each other. They are widely used in various industries, including oil and gas, water treatment, and mining.

How Gravity Separators Work

A gravity separator typically consists of a vessel where the fluid mixture enters. Due to the density difference, the heavier particles settle to the bottom of the vessel, while the lighter fluid remains on top. The separated phases can then be withdrawn from the vessel.

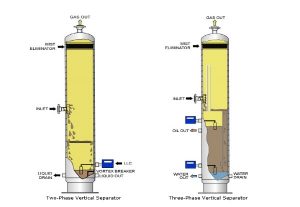

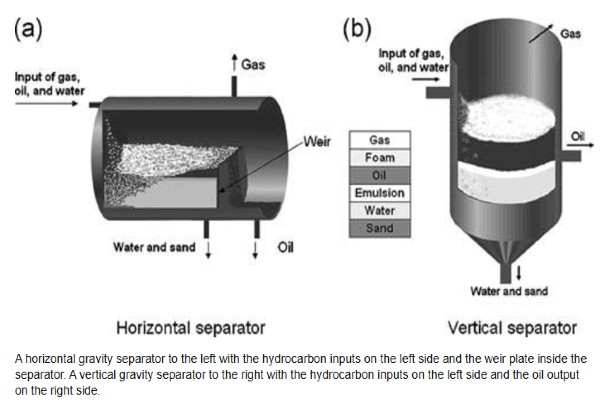

Pictured above: Gravity Separators

Design Considerations for Gravity Separators

- Vessel Geometry:

- Vertical Separators: These are commonly used for separating solids from liquids. The height of the vessel is crucial to allow sufficient settling time for the particles.

- Horizontal Separators: These are often used for separating liquid-liquid mixtures. The length of the vessel provides a longer residence time for phase separation.

- Inlet and Outlet Design:

- The inlet design should minimize turbulence and prevent short-circuiting of the fluid flow.

- The outlet design should ensure efficient removal of the separated phases.

- Baffles and Weirs:

- Baffles can be used to reduce turbulence and improve separation efficiency.

- Weirs can be used to control the liquid levels in the separator.

- Sludge Removal:

- A mechanism for removing the settled solids, such as a sludge valve or pump, is essential.

- Material Selection:

- The material of construction should be selected based on the fluid properties, temperature, and pressure.

Key Design Parameters:

- Vessel Diameter and Height: These dimensions determine the capacity of the separator.

- Inlet Velocity: The inlet velocity should be low to minimize turbulence.

- Residence Time: The time required for particles to settle to the bottom.

- Solid Particle Size and Density: These properties influence the settling velocity.

- Liquid Viscosity: Viscosity affects the settling rate of particles.

Applications of Gravity Separators

- Oil and Gas: Separating oil, water, and gas.

- Water Treatment: Removing suspended solids from wastewater.

- Mining: Separating minerals from ore.

- Food Processing: Separating solids from liquids in food products.

Note: While gravity separators are a simple and effective solution for many applications, they may not be suitable for separating very fine particles or high-viscosity fluids. In such cases, other separation techniques, such as filtration or centrifugation, may be more appropriate.

By carefully considering these design factors and selecting the appropriate geometry and operating conditions, gravity separators can be effectively used to separate solid particles from liquids or different liquid phases.