Horizontal separators are ideally suited to wellstreams having high gas-oil ratios, constant flow, and small liquid surge characteristics.

Horizontal separators are smaller and less expensive than vertical separators for a given gas capacity. Liquid particles in the wellstream travel horizontally and downward at the same time as a result of two forces acting upon them-the horizontal force of the gas stream and the downward force of gravity. Therefore, higher gas velocities can be permitted in horizontal separators and still obtain the same degree of separation as in vertical separators. Also, the horizontal separators have a much greater gas-liquid interface area than other types, which aids in the release of solution gas and reduction of foam. A special de-foaming section is used when severe foaming of the inlet stream is anticipated.

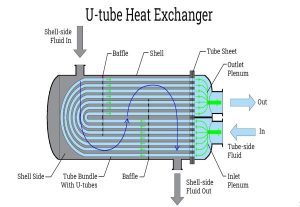

Pictured above: Horizontal separator Diagram

The horizontal configuration is best suited for liquid-liquid-gas, or three-phase, separations because of the large interfacial area available between the two liquid phases. In addition to being easier to hook up, easier to service, and easier to skid-mount, horizontal separators can be stacked in a piggy-back fashion to form stage separation assemblies and minimize horizontal space requirements.

Applications:

- Areas where there are vertical height limitations

- Foamy production where the larger liquid surface area available will allow greater gas breakout and foam breakdown

- Three-phase separation applications for efficient liquid-liquid separation

- Upstream of process equipment, which will not tolerate entrained liquid droplets in the gas

- Downstream of equipment causing the liquid formation

- Wellstreams having a high gas-to-oil ratio and constant flow with little or no liquid surges

- Applications requiring bucket and weir construction for three-phase operation

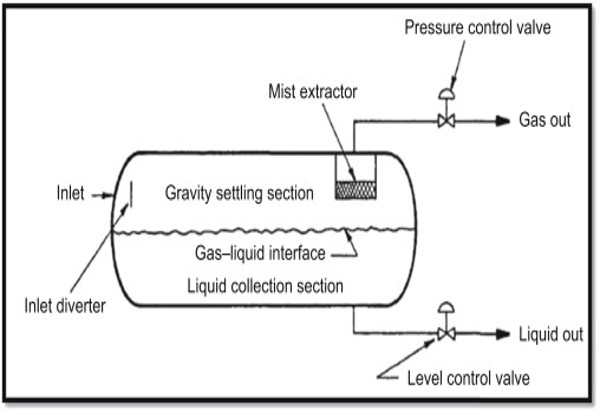

Pictured above: Horizontal Separator in service