A Crucial Component in Fluid Processing

Liquid separators are essential equipment used in various industries, including oil and gas, chemical processing, and water treatment. These devices are designed to separate liquids from gases or to separate different liquid phases from each other.

They are excellent choices for applications where large slugs of liquids need to be prevented from entering the vacuum pump. Capturing these liquids before they can enter the vacuum pump will reduce pump failure, oil degradation, and production downtime. These separators can be used on all types of vacuum pumps including Liquid Ring, Piston, Vane, Screw and Side channel blowers.

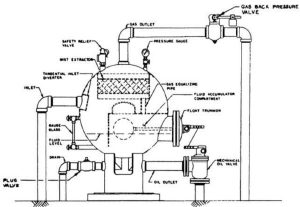

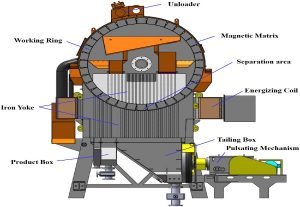

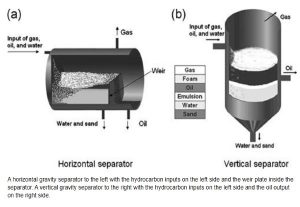

Pictured above: Liquid Separators

Types of Liquid Separators

There are several types of liquid separators, each with its own unique design and application:

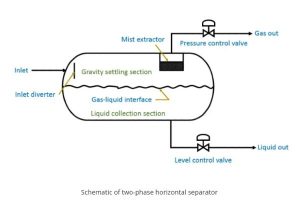

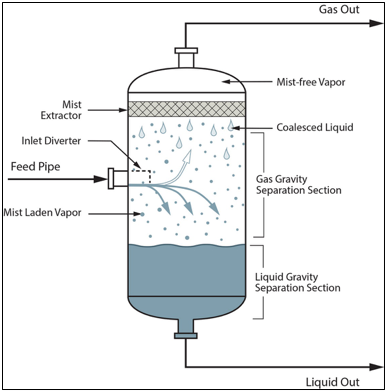

Gravity Separators

- Principle: Relies on the difference in density between liquid and gas or between different liquid phases.

- Design: Typically vertical or horizontal vessels with internal baffles to enhance separation efficiency.

- Applications: Oil and gas production, wastewater treatment, and chemical processing.

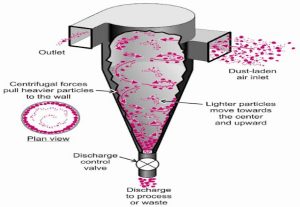

Centrifugal Separators

- Principle: Uses centrifugal force to separate liquids from solids or different liquid phases.

- Design: High-speed rotating bowl or disc-stack design.

- Applications: Oil and gas production, food processing, and chemical processing.

Filter Separators

- Principle: Removes solid particles from liquids using a filter medium.

- Design: Various filter media, such as cartridge filters, bag filters, or membrane filters.

- Applications: Water treatment, chemical processing, and pharmaceutical industries.

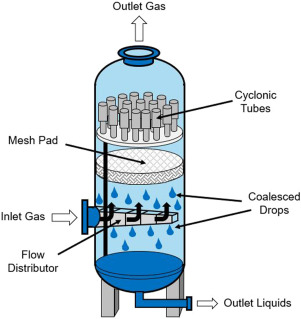

Coalescer Separators

- Principle: Coalesces small liquid droplets into larger droplets, which can then be easily separated.

- Design: Typically uses a coalescing media, such as mesh or fibrous materials.

- Applications: Oil and gas production, chemical processing, and gas treatment.

Key Factors to Consider When Selecting a Liquid Separator

- Fluid Properties: Density, viscosity, and the presence of solids or emulsions.

- Flow Rate: The volume of fluid to be processed.

- Separation Efficiency: The required degree of separation.

- Pressure and Temperature: The operating conditions of the process.

- Maintenance Requirements: The frequency and complexity of maintenance.

- Cost: The initial purchase cost and ongoing operating costs.

By carefully considering these factors, engineers can select the most appropriate liquid separator for a specific application.

Pictured above: Liquid Separators diagram

Importance of Liquid Separators

Liquid separators play a critical role in various industries by:

- Improving Product Quality: Removing impurities and contaminants from liquids.

- Increasing Process Efficiency: Ensuring smooth and uninterrupted operations.

- Protecting Downstream Equipment: Preventing damage caused by liquid carryover.

- Reducing Environmental Impact: Minimizing the release of pollutants.

Stokes' Law and Liquid Separation

Stokes’ Law is a fundamental principle underlying the operation of many liquid separators, especially gravity separators. It describes the settling velocity of particles in a fluid. Larger, denser particles settle faster in less viscous fluids. By understanding Stokes’ Law, engineers can design separators with optimal dimensions and residence times to ensure efficient separation.

The equation for Stokes’ Law is:

v = (2/9) * (ρp – ρf) * g * r² / μ

Where:

- v: Terminal settling velocity of the particle

- ρp: Density of the particle

- ρf: Density of the fluid

- g: Acceleration due to gravity

- r: Radius of the particle

- μ: Dynamic viscosity of the fluid

By analyzing this equation, we can see how factors like particle size, density difference, and fluid viscosity influence the separation process. For instance, increasing the density difference or particle size will increase the settling velocity, leading to faster separation.

By understanding the different types of liquid separators and their applications, engineers can optimize process efficiency and product quality while minimizing environmental impact.