Magnetic Separators

A Powerful Tool for Material Separation

Magnetic Separators utilize magnetic forces to separate magnetic materials from non-magnetic materials. They are widely used in various industries, including mining, recycling, and food processing.

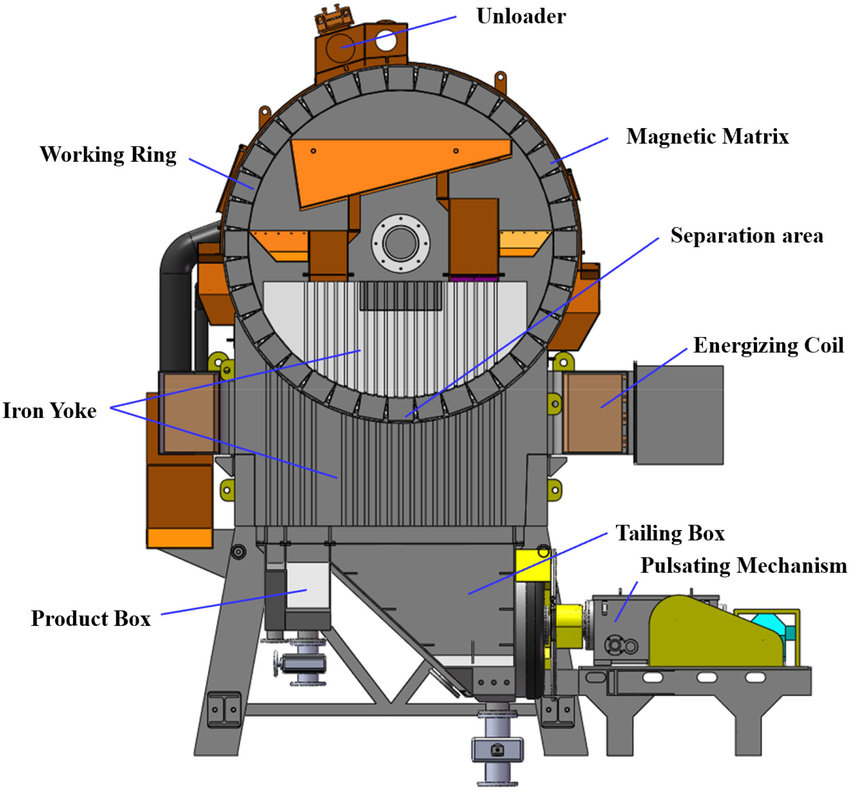

Pictured above: Vertical Ring High-gradient Magnetic Separation system

Types of Magnetic Separators:

Drum Separators:

- A rotating drum with a magnetic core attracts magnetic particles from a conveyor belt or chute.

- Design Data: Drum diameter, drum speed, magnetic field strength, and conveyor belt speed.

- Key Considerations: Magnetic field intensity, drum speed, and conveyor belt speed.

Overband Separators:

- A magnetic plate is placed over a conveyor belt to attract magnetic particles from the material being conveyed.

- Design Data: Magnet strength, conveyor belt speed, and magnetic plate dimensions.

- Key Considerations: Magnet strength, conveyor belt speed, and distance between the magnet and the material.

High-Gradient Magnetic Separators (HGMS):

- A strong magnetic field is applied to a matrix of fine ferromagnetic wires. Magnetic particles are attracted to the wires and captured.

- Design Data: Magnetic field strength, matrix geometry, and flow rate of the material.

- Key Considerations: Magnetic field strength, matrix design, and particle size distribution.

Eddy Current Separators:

- A strong magnetic field induces eddy currents in conductive materials, causing them to be repelled from the magnetic field.

- Design Data: Magnetic field strength, coil configuration, and conveyor belt speed.

- Key Considerations: Magnetic field strength, coil design, and material conductivity.

Design Considerations for Magnetic Separators:

- Magnetic Field Strength: The strength of the magnetic field determines the efficiency of the separation process.

- Particle Size and Shape: The size and shape of the particles affect their susceptibility to magnetic forces.

- Material Properties: The magnetic properties of the materials being separated influence the separation process.

- Flow Rate: The flow rate of the material affects the residence time in the magnetic field.

- Separator Geometry: The geometry of the separator, including the shape and size of the magnetic components, impacts the separation efficiency.

By carefully considering these design factors, engineers can select and design magnetic separators that meet the specific needs of a particular application.

Key Applications of Magnetic Separators:

- Mining: Separating iron ore from other minerals.

- Recycling: Separating ferrous and non-ferrous metals from waste materials.

- Food Processing: Removing metal contaminants from food products.

- Chemical Industry: Separating magnetic catalysts from reaction products.

Magnetic separators are a valuable tool for separating materials based on their magnetic properties. By understanding the principles of magnetic separation and the key design considerations, engineers can optimize the performance of these devices.