Material Selection for High-Pressure Applications: What Engineers Need to Know

When it comes to designing pressure vessels, one of the most critical decisions engineers face is selecting the right material. In high-pressure environments, the wrong choice can lead to catastrophic failure, regulatory violations, or costly downtime. The right material, on the other hand, ensures safety, performance, and long-term reliability.

In this post, we’ll break down the key factors that drive material selection for high-pressure applications—and the trade-offs engineers need to keep in mind.

Key Considerations in Material Selection

- Pressure and Temperature Ratings

The material must be able to withstand the maximum allowable working pressure (MAWP) and the operating temperature range. Elevated temperatures can reduce material strength, which must be factored into design calculations. - Corrosion Resistance

For vessels exposed to aggressive chemicals, high humidity, or corrosive media, materials with strong corrosion resistance—such as stainless steel or nickel alloys—are crucial. Internal coatings or linings can also be used, but they must be compatible with the base material. - Ductility and Toughness

Ductile materials can deform under stress without cracking, which is vital in preventing brittle fracture—especially in cold environments or under rapid pressure changes. - Weldability and Machinability

Manufacturing constraints also influence material choice. A material may have excellent strength but be extremely difficult or expensive to weld. Engineers must ensure the selected material can be fabricated efficiently and safely. - Cost and Availability

Sometimes the best technical option isn’t the best economic option. Lead times, market volatility, and global supply chain disruptions all play a role in the final decision.

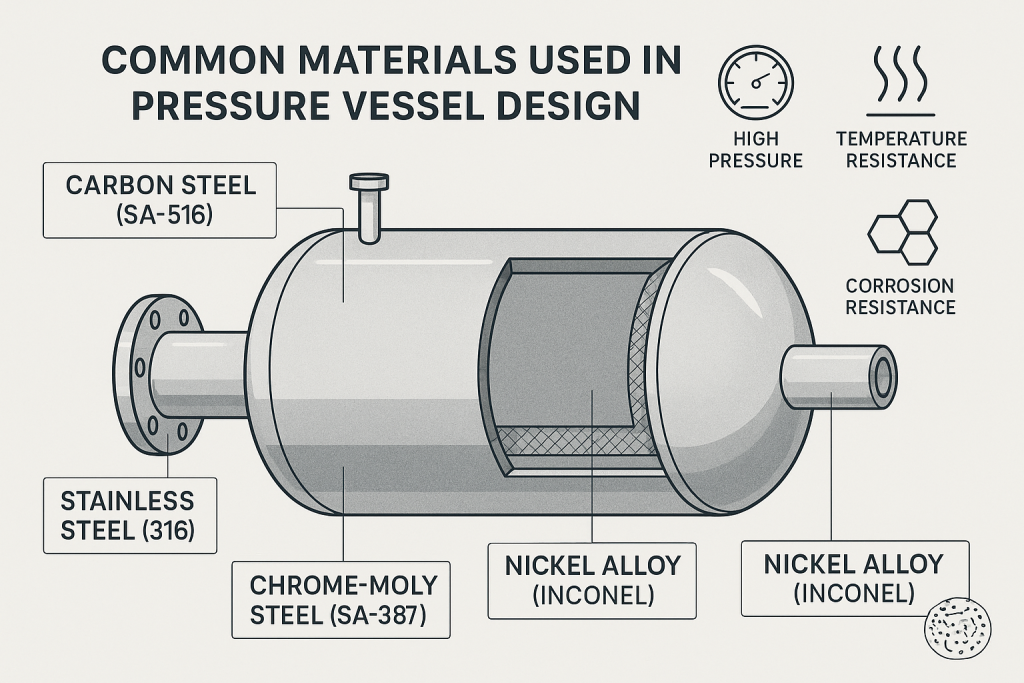

Pictured above: Material Selection for High-Pressure Applications

Common Materials for High-Pressure Vessels

- Carbon Steel (e.g., SA-516 Grade 70)

Widely used due to its strength, weldability, and cost-effectiveness. However, it lacks corrosion resistance and is best suited for non-corrosive environments. - Stainless Steel (e.g., 304/316)

Offers excellent corrosion resistance and is often used in the food, pharmaceutical, and chemical processing industries. Its higher cost is offset by longer service life in harsh environments. - Chrome-Moly Steels (e.g., SA-387)

Designed for high-temperature service, these steels are commonly used in power generation and petrochemical applications. - Nickel Alloys (e.g., Inconel, Hastelloy)

These high-performance materials provide superior resistance to heat and corrosion but come with a significant cost premium. They’re typically reserved for the most demanding environments.

Codes and Standards That Govern Material Use

Material selection for pressure vessels isn’t just about performance—it must comply with regulatory requirements. Key standards include:

- ASME Boiler and Pressure Vessel Code (Section II) – Governs material specifications and allowable stress values.

- ASME Section VIII, Division 1 and 2 – Provides design rules for pressure vessels, including considerations for material thickness and testing.

- ASTM Standards – Define material properties and testing methods.

Compliance with these standards ensures not just safety but also inspection and certification readiness.

Special Considerations

- Cladding and Lining

For environments where corrosion is a risk but cost is a concern, carbon steel vessels can be clad or lined with corrosion-resistant alloys. - Fatigue and Cyclic Loading

In vessels subjected to frequent pressure cycles, fatigue resistance becomes a key property. Material toughness and flexibility are essential to prevent crack propagation. - Supply Chain Disruptions

In 2025, supply chain challenges remain a real issue. Engineers need to balance ideal material specifications with procurement feasibility and lead times.

Conclusion

Material selection for high-pressure applications is a balancing act between mechanical performance, environmental resistance, manufacturability, cost, and compliance. By understanding the strengths and limitations of each material—and the standards that govern their use—engineers can design vessels that are safe, efficient, and built to last.

When in doubt, early collaboration between materials engineers, designers, and procurement teams is the best way to ensure the right choice from the start.