B31.1 Piping Design

The selection of appropriate materials is a critical aspect of B31.1 piping design. The choice of material depends on factors such as temperature, pressure, corrosion resistance, and cost.

Key Considerations for Material Selection:

- Mechanical Properties:

- Yield Strength: The material must have sufficient yield strength to withstand the applied loads.

- Tensile Strength: The material must be able to resist tensile stresses.

- Ductility: The material should have adequate ductility to accommodate plastic deformation.

- Toughness: The material should be tough to resist brittle fracture.

- Corrosion Resistance:

- The material should be resistant to corrosion from the fluid being transported.

- Corrosion allowance may need to be considered in the design to account for potential corrosion.

- Weldability:

- The material should be weldable using appropriate welding techniques.

- Weldability is influenced by factors such as carbon content and alloying elements.

- Fatigue Strength:

- For cyclic loading conditions, the material should have adequate fatigue strength to prevent fatigue failure.

- Cost:

- The cost of the material is an important factor to consider, especially for large-scale projects.

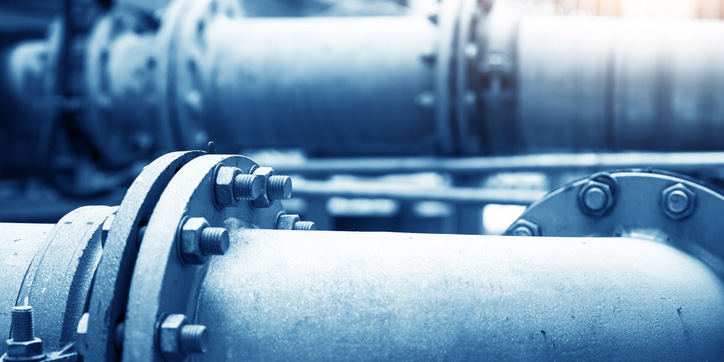

Pictured above: piping-design

Common Materials Used in B31.1 Piping Systems:

- Carbon Steel:

- Widely used for low-temperature and low-pressure applications.

- Examples: ASTM A106, A53, A333 Gr. 6

- Low-Alloy Steel:

- Used for higher temperature and pressure applications.

- Examples: ASTM A335 Gr. P11, P22

- Stainless Steel:

- Used for corrosive environments and high-temperature applications.

- Examples: ASTM A312 Gr. 304, 316

- Nickel Alloys:

- Used for severe corrosive environments and high-temperature applications.

- Examples: Inconel, Hastelloy

Material Selection Considerations:

- Code Requirements: The ASME®® B31.1 Code specifies the allowable stresses for different materials.

- Corrosion Allowance: A corrosion allowance may be added to the pipe wall thickness to account for potential corrosion.

- Fabrication and Welding: The material should be suitable for the welding processes to be used.

- Inspection and Testing: The material should be amenable to non-destructive examination techniques.

Pictured above: piping

By carefully selecting materials and considering the factors discussed above, engineers can design piping systems that are both safe and cost-effective.