Microchannel Heat Exchangers: A Tiny Powerhouse

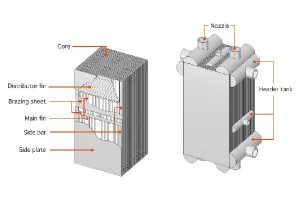

Microchannel heat exchangers are a type of heat exchanger with channels that have characteristic dimensions in the micrometer range. These tiny channels offer significant advantages in terms of heat transfer efficiency and compact design.

Pictured above: A close up of a Microchannel

How Microchannel Heat Exchangers Work

In a microchannel heat exchanger, the two fluids flow through microchannels etched or machined into metal plates. The large surface area-to-volume ratio and short flow paths enable efficient heat transfer.

Key Design Considerations for Microchannel Heat Exchangers:

- Channel Geometry: The geometry of the channels, including their width, depth, and spacing, significantly impacts the heat transfer performance and pressure drop.

- Plate Material: The material of the plates should be selected based on its thermal conductivity, corrosion resistance, and mechanical strength.

- Manufacturing Process: Precise manufacturing techniques, such as micromachining or etching, are required to create the microchannels.

- Fluid Flow Distribution: Ensuring uniform flow distribution within the channels is crucial for optimal performance.

- Pressure Drop: The pressure drop across the heat exchanger should be minimized to reduce pumping power requirements.

- Fouling and Corrosion: The design should consider fouling and corrosion mechanisms and incorporate measures to mitigate their effects.

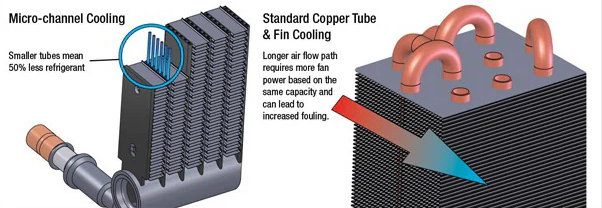

Pictured above: Micro-channel cooling

Advantages of Microchannel Heat Exchangers:

- High Heat Transfer Efficiency: The large surface area-to-volume ratio enables efficient heat transfer.

- Compact Design: Microchannel heat exchangers are very compact, making them ideal for space-constrained applications.

- Precise Temperature Control: The small channel dimensions allow for precise temperature control.

- High Heat Flux: Can handle high heat fluxes.

Challenges in Microchannel Heat Exchanger Design and Manufacturing:

- Manufacturing Complexity: The fabrication of microchannels requires advanced manufacturing techniques and precise control.

- Pressure Drop: The high surface area can lead to increased pressure drop.

- Fouling: Fouling can significantly reduce the performance of microchannel heat exchangers.

Applications of Microchannel Heat Exchangers:

- Electronics Cooling: Cooling of high-power electronic components.

- Automotive: Engine cooling and waste heat recovery.

- Aerospace: Heat exchangers for aircraft and spacecraft.

- Chemical Processing: Heat exchange in compact and efficient systems.

Microchannel heat exchangers offer a promising solution for future heat transfer challenges, enabling more efficient and compact systems.

By carefully considering the design challenges and leveraging advanced manufacturing techniques, engineers can design and manufacture high-performance microchannel heat exchangers for a wide range of applications.