Natural Gas Dehydration: Ensuring Dry Gas for Efficient Operations

Natural gas dehydration is the process of removing water vapor from natural gas.

A gas dehydration system is used by oil and gas producers to dehydrate natural gas into a state where it can be sold downstream.

In the oil and gas industry, plant operators are constantly trying to find ways to remove contaminants and produce purer products. A major problem contaminant associated with natural gas is water vapor. To get rid of moisture from recovered natural gas, industrial manufacturers use different dehydration methods, like triethylene glycol processes.

Pictured above: Natural Gas Dehydration

How Does Natural Gas Dehydration Work?

Natural gas dehydration is the process of removing water vapor from natural gas. A gas dehydration system is used by oil and gas producers to dehydrate natural gas into a state where it can be sold downstream.

Natural gas, a valuable energy source, often contains water vapor. This moisture can cause various operational issues, such as:

- Hydrate Formation: Water vapor can combine with hydrocarbons to form solid hydrates, which can clog pipelines and equipment.

- Corrosion: Water can accelerate corrosion in pipelines and processing facilities.

- Reduced Heating Value: Water vapor dilutes the natural gas, reducing its heating value.

To mitigate these problems, natural gas dehydration is a crucial process that removes water vapor from the gas stream.

Why is Natural Gas Dehydration Important?

Natural gas dehydration is essential for several reasons:

- Pipeline Protection: Prevents hydrate formation and corrosion, ensuring the integrity of pipelines.

- Enhanced Heating Value: Increases the heating value of the gas, improving its efficiency.

- Reduced Operational Costs: Minimizes maintenance and downtime due to equipment failures.

- Environmental Compliance: Helps meet environmental regulations by reducing emissions.

By effectively removing water vapor from natural gas, dehydration processes play a vital role in ensuring the reliable and efficient transportation and utilization of this valuable energy resource.

Methods For Dehydrating Natural Gas

There are several methods for natural gas dehydration, but we will focus on three of the most common techniques:

- TEG dehydration

- Membrane dehydration

- Dehydration using adsorbents

- Natural gas dehydration with TEG

Glycol dehydration is one of the most common and economical processes for reducing water content in natural gas and natural gas liquids (NGLs). According to the EPA, there are about 3500 operational TEG units in the U.S. alone.

The process utilizes Triethylene Glycol (TEG), a highly viscous liquid that is colorless, odorless, and stable at room temperature to desiccate natural gas. TEG is an excellent absorbent for dehydration of natural gas due to its hygroscopic nature.

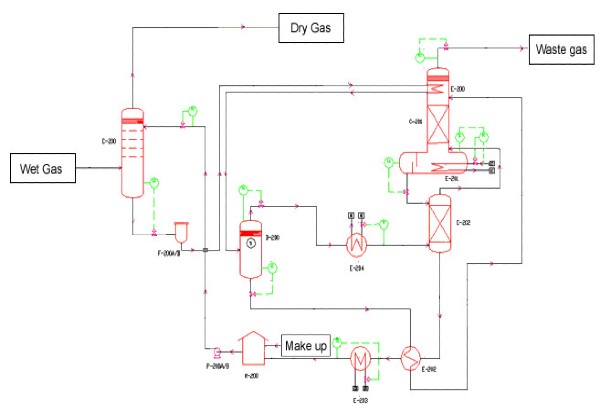

How does TEG gas dehydration work?

TEG dehydration is carried out in a dehydration unit for natural gas called a TEG unit. The dehydration process is quite straightforward; wet gas enters the unit from the inlet at the bottom of the separator and passes through the glycol contactor.

Glycol flows into the contactor tower from the top of the separator unit. A special bubble cap inside the unit maximizes wet gas – glycol contact for maximum dehydration. TEG dehydration can reduce natural gas water saturation to less than 5lbm/MMScf.

The dehydrated gas is collected from the top of the unit and channeled to supply pipelines or advanced processing units while the water-rich glycol is sent to the re-purification unit to recover pure glycol.

Advantages: Highly efficient, can handle high water content, and is suitable for a wide range of operating conditions.

Pictured above: Natural Gas Dehydration Unit With TEG (Tri Ethylene Glycol)

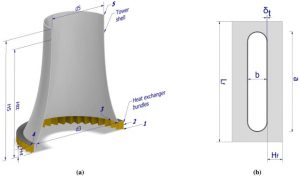

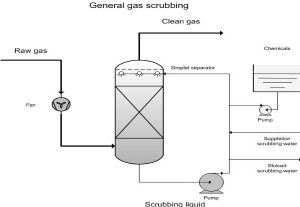

How does Membrane Dehydration work?

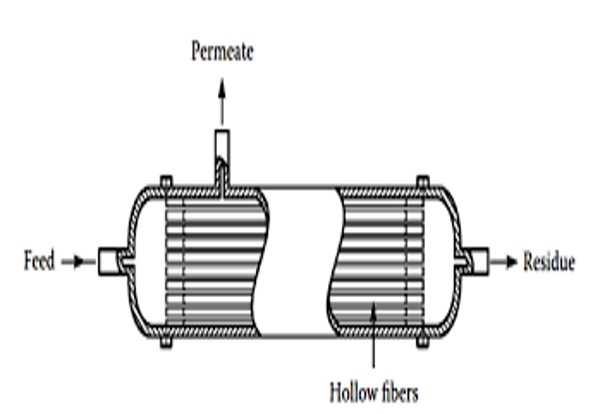

Membrane dehydration is an alternative method for natural gas desiccation which utilizes a hollow-fiber membrane for water vapor removal. It is a cost-effective and durable process for natural gas dew point control as well as H2O, CO2, and H2S removal.

In membrane dehydration, a gas compressor is used to pump wet gas through a hollow-fiber membrane which separates the low-permeability dry gas component from the high-permeability water molecules. Membrane systems are preferred due to their high durability and efficiency and compliance with stringent emission regulations.

Pictured above: Membrane Dehydration

Dehydration using solid adsorbents

Dehydration of natural gas using absorbents is a low-cost technique for ensuring dry gas supply. Solid adsorbents are hygroscopic in nature (exhibit a strong affinity for water). Common adsorbents used for natural gas desiccation include silica gel, molecular sieves, and alumina.

How do adsorbents remove water vapor from natural gas?

- Silica gel (SiO2) is a porous hygroscopic solid at room temperature which can be used to absorb moisture from natural gas. Silica is commonly manufactured as small beads and placed in a desiccant unit to dry the gas.

Alumina or Aluminium oxide (Al2O3) is a porous, crystalline solid derived from bauxite with strong hygroscopic properties. Alumina is an excellent adsorbent for dehydrating natural gas.

Other Methods

Solid Desiccant Dehydration

Process: Solid desiccants, such as molecular sieves or activated alumina, absorb water vapor from the gas stream. The desiccant is regenerated by heating to release the absorbed water.

Advantages: Low operating costs, minimal environmental impact, and can handle high water content.

Molecular Sieve For Dehydration

We can also use a molecular sieve for dehydration of natural gas. Molecular sieves are commonly manufactured as solids compounds of a few millimeters thickness and width. They are especially useful for dehydrating sour natural gas containing multiple aromatic compounds.

Refrigeration Dehydration

Process: The gas is cooled to a temperature below the dew point of water vapor, causing the water to condense.

Advantages: Simple process, low maintenance, and can be used for both dehydration and sweetening.