Navigating the Path to U and U2 Stamp Certifications

Obtaining a U-Stamp or U2-Stamp from the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI) is a significant achievement for manufacturers and fabricators of pressure vessels and boilers. These certifications signify adherence to rigorous quality, safety, and performance standards.

Understanding U-Stamp and U2-Stamp Certifications

- U-Stamp: This certification authorizes a manufacturer to build and stamp new pressure vessels and boilers. It signifies compliance with the ASME® Boiler and Pressure Vessel Code (BPVC).

- U2-Stamp: This certification authorizes a manufacturer to repair and alter existing pressure vessels and boilers. It also requires adherence to the ASME® BPVC.

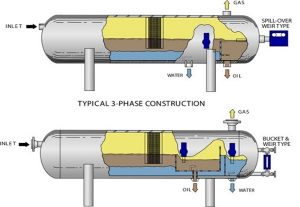

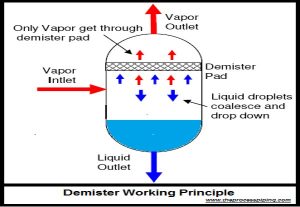

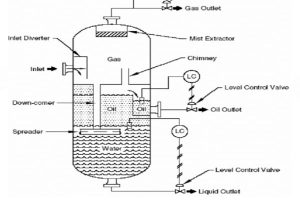

Pictured above: Pressure Vessels

Key Design Considerations for U-Stamp and U2-Stamp Certified Products:

Material Selection:

- Code-Compliant Materials: The materials used in the construction of pressure vessels and boilers must comply with the ASME® BPVC.

- Material Testing: Materials must be tested to ensure they meet the required mechanical properties.

Design Calculations:

- Stress Analysis: The design must be analyzed to ensure that the stresses induced in the vessel or boiler are within allowable limits.

- Fatigue Analysis: For cyclic loading conditions, fatigue analysis is required to prevent fatigue failure.

- Thermal Stress Analysis: Thermal stresses resulting from temperature differences must be considered.

Manufacturing Processes:

- Welding: Welding procedures must be qualified, and welders must be certified.

- Non-Destructive Examination (NDE): NDE techniques such as radiography, ultrasonic testing, and magnetic particle inspection must be used to verify the quality of welds and other components.

- Heat Treatment: Heat treatment processes must be controlled to achieve the desired mechanical properties.

- Machining and Fabrication: Machining and fabrication processes must be performed to precise tolerances.

Quality Assurance Program:

- Document Control: A robust document control system must be in place to manage design documents, procedures, and records.

- Inspection and Testing: Regular inspections and tests must be conducted to ensure compliance with the ASME® BPVC.

- Corrective Action: A system for identifying and correcting nonconformities must be in place.

Additional Considerations for U2-Stamp:

- Repair Procedures: Repair procedures must be documented and approved.

- Material Certification for Repair Parts: Repair parts must be certified to the same standards as original materials.

- Post-Repair Inspection: Repaired components must be inspected to ensure they meet the original design requirements.

By adhering to these design considerations and the requirements of the ASME® BPVC, manufacturers can successfully obtain and maintain U-Stamp and U2-Stamp certifications, ensuring the safety and reliability of their products.