Plate Fin Heat Exchangers

A Compact and Efficient Solution

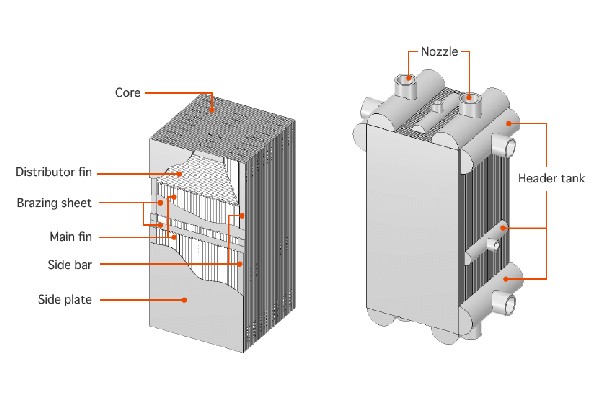

Plate fin heat exchangers are a type of compact heat exchanger that is widely used in various industries, including automotive, HVAC, and electronics. They are known for their high heat transfer efficiency and compact design.

How They Work

A plate fin heat exchanger consists of a core, which is a stack of corrugated plates, and fins, which are attached to the plates to increase the surface area for heat transfer. One fluid flows through the channels formed by the plates, while the other fluid flows across the fins. The fins enhance heat transfer by increasing the surface area and promoting turbulent flow.

Pictured above: How Plate Fin Heat Exchangers Work

Advantages vs Disadvantages

Advantages:

- High Heat Transfer Efficiency: The large surface area and turbulent flow enhance heat transfer.

- Compact Design: Plate fin heat exchangers are very compact, making them ideal for space-constrained applications.

- Lightweight: They are lightweight, making them suitable for mobile applications.

- Versatility: Can handle a wide range of fluids and temperature differences.

- Low Pressure Drop: The low pressure drop across the heat exchanger reduces energy consumption.

Disadvantages:

- Complex Manufacturing: The manufacturing process for plate fin heat exchangers is complex.

- Susceptibility to Fouling: The fins can become fouled with dirt and debris, reducing heat transfer efficiency.

- Limited Pressure Rating: Typically limited to lower pressure applications.

Key Considerations for Design and Selection:

- Core Configuration: The arrangement of the plates and fins can affect the heat transfer performance.

- Fin Material: The fin material should be selected based on the fluid compatibility and temperature requirements.

- Plate Material: The plate material should be selected for its strength, corrosion resistance, and thermal conductivity.

- Brazing: The brazing process must be carefully controlled to ensure a strong and reliable joint.

Plate fin heat exchangers are a highly efficient and compact solution for a wide range of heat transfer applications. Their versatility, high performance, and low weight make them a popular choice in many industries.

Considering these factors, engineers can select and design plate fin heat exchangers that meet the specific needs of a particular application.