Printed Circuit Heat Exchangers (PCHEs): A High-Performance Solution

Printed Circuit Heat Exchangers (PCHEs) are a specialized type of heat exchanger that offers exceptional heat transfer performance in a compact footprint. They are widely used in industries such as aerospace, automotive, and electronics.

How PCHEs Work

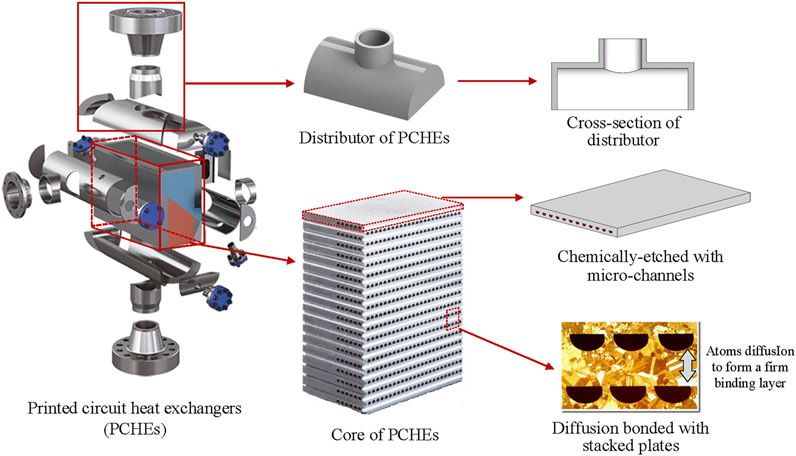

PCHEs consist of a stack of thin metal plates, etched with microchannels that form intricate flow passages. The two fluids to be exchanged flow through these microchannels, separated by the plate walls. The large surface area and short flow paths enable efficient heat transfer.

Pictured above: Assembly pieces of a PCHE

Key Design Considerations for PCHEs:

- Channel Geometry: The geometry of the channels, including their width, depth, and spacing, significantly impacts the heat transfer performance and pressure drop.

- Plate Material: The material of the plates must be selected based on its thermal conductivity, corrosion resistance, and mechanical properties.

- Gasket Material: The gasket material must be able to withstand the operating temperature and pressure, and provide a leak-tight seal.

- Plate Thickness: The thickness of the plates affects the heat transfer area and mechanical strength.

- Flow Distribution: The flow distribution within the channels must be uniform to maximize heat transfer efficiency.

- Pressure Drop: The pressure drop across the heat exchanger should be minimized to reduce pumping power requirements.

Pictured above: Structure of printed circuit heat exchangers (PCHEs)

Advantages of PCHEs:

- High Heat Transfer Efficiency: The large surface area and short flow paths enable efficient heat transfer.

- Compact Design: PCHEs are compact and lightweight, making them ideal for space-constrained applications.

- Precise Temperature Control: The intricate channel design allows for precise control of temperature gradients.

- Corrosion Resistance: PCHEs can be fabricated from corrosion-resistant materials.

- Low Maintenance: The absence of moving parts reduces maintenance requirements

Challenges in PCHE Design and Manufacturing:

- Manufacturing Complexity: The fabrication of PCHEs requires precise manufacturing techniques to ensure accurate channel dimensions and tight tolerances.

- Leakage: The sealing of the channels must be carefully designed to prevent leakage.

- Fouling: Fouling can reduce the heat transfer performance, and cleaning techniques must be considered.

PCHEs offer a compelling solution for applications demanding high heat transfer rates, compact size, and precise temperature control. As technology advances, we can expect to see further innovations in PCHE design and manufacturing, enabling even more efficient and effective heat exchange solutions.

By carefully considering these design factors and addressing the challenges, engineers can design and manufacture high-performance PCHEs for a wide range of applications.