Sand Separator

The Sand Separator is a pressure vessel specifically designed for separating well fluids into oil, gas, and water. It features several chambers connected by pipes and pressure vessel connections and relief valves. Sand Separators are usually on a platform near the wellhead, tank battery or manifold to separate the fluids collected from production wells.

Some wellstreams produce quantities of sand and sediment with oil and gas. Unless the separator is designed to handle sand, the outlet liquid connections, the bottom of the separator, and other connections in the liquid section will become plugged up with sand and the separator will become inoperative.

Pictured above: Sand Separator in West Texas

In the most basic sense, a sand separator is anything designed to separate sand or other solid particulate matter from water. They do not separate all of the solids from the liquid but are an essential initial part of the process of getting a lot of solid particles out of the liquid. This approach is used in waste management and in micro irrigation systems as well as within the oil and gas industry.

In the oil and gas industry, it is more commonly known as a separator and is a core component of extracting oil from earth and sand. Sand separators are an integral part in protecting downstream production equipment from well-formation sand and/or frac sand.

How does a Sand Separator work?

The primary technique used in the Sand Separator is centrifugal force combined with gravity. Here, the materials are loaded to a centrifuge and spun. The materials, thus, get collected in various locations based on their weight. The sand, generally, is pushed to the bottom which can then be separated and removed. The oil, gas, and other lightweight particles remain at the top without mechanical agitation. Once the separation occurs, a filtering system will assist in clearing out finer particles and materials.

To create a homogenous stream, there is a need for both oil and gas separators and sand separators. These types of equipment are used as the first step to processing and refining crude oil. They help cut down issues related to oil and gas drastically. They help prevent leaks caused by the transportation of oil, gas, and sand at once.

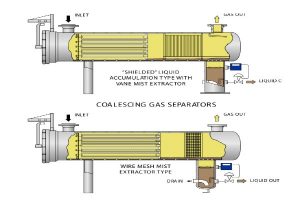

Pictured above: Cylindrical Sand Separators

How Separators Work in the Oil and Gas Industry

The oil and gas industry uses sand separators to separate oil and gas for purification. Centrifugal force combined with gravity is the primary means used to separate solids from oil and gas. The gravity first separates the gas from the oil components in the separator, after which the gas and oil are extracted separately. Heaters come in handy to aid flow throughout the system.

For extracting oil, a sand separator may be a two-phase or three-phase separator.

- A two-phase separator strictly separates the sand from the extracted crude oil.

- A three-phase separator is needed when gas needs to be separated as well.

For example, when placing a mixture of oil and sand in a centrifuge and then spinning it, the sand sinks to the bottom where it can be separated and removed, leaving the oil on top. If extracting gas, the gas tends to rise to the top without you having to take any action. Once you have separated these substances, usually a filtering system filters out the remaining fine particles and contaminants.

Why Should You Use a Sand Separator?

A two-phase Sand Separator can quickly separate sand from liquid, like crude oil used in the oil and gas industry. A three-phase separator can separate the third component, usually gas, resulting in gas, oil, and particulate equipment. Sand Separators, in general, are the most economical and efficient equipment to separate sand and sediments.

A sand separator coupled with a filtration system can remove most of the particulate from oil, thus making it easier to recover and transport. Without this system, it can exert more pressure on the extraction system, wasting the energy and resources needed to filter out large amounts of particulates or invest in more complicated refining devices.

What Are Some Kinds of Sand Separators?

Vertical Sand Separator

Cone bottoms are installed in vertical separators with sand jets so the sand can periodically be stirred and dumped. The cone can be the bottom head of the vessel, or a false cone can be fabricated inside the lower portion of the separator to achieve the same results at a more economical cost.

Horizontal Sand Separators

Horizontal separators require more elaborate modifications. Usually, more dump connections are provided and special baffles over these connections (referred to as sand pans) are provided to prevent them from becoming plugged. Sand jets running the full length of the separator are provided to stir the sand before dumping. In selecting which separator to use, local experience is an important factor.

Spherical Sand Separators

A spherical sand separator is a vessel designed to separate sand and any other heavy solids from liquid.

Spherical sand traps offer the best available technology to provide robust service across a wide range of flow conditions. Its spherical design provides superior performance compared to traditional vertical and tangential inlet sand traps, which are limited in capability and in performing within their designed flow rate ranges. As robust, erosion-resistant, compact, and portable technology that is easy to operate and maintain, some sand traps do not incorporate any screens or filters that require frequent disassembly and cleaning.

Unlike standard sand separators, a Spherical Sand Separator does not utilize a cylindrical shell. This sphere allows for a more user-friendly, easier-to-reach, approach while also increasing gas capacity by 2.3x and liquid/sand capacity by 3x.

Cylindrical Sand Separators

A cylindrical sand separator is a mechanical device designed to remove sand and other solid particles from liquid streams, typically shaped like a cylinder with an inlet and outlet, where the liquid flows through, causing heavier particles like sand to settle at the bottom due to gravity and centrifugal force, allowing the cleaner liquid to exit at the top; essentially acting as a filter for large solid particles like sand.

Cyclonic Sand Separator

A cyclonic sand separator is a vessel used to separate sand and any other heavy solids from liquid more efficiently using internals specifically designed to create a cyclonic motion. It is a pressurized vessel used to separate sand from liquid, it’s also designed for flow back of effluent containing proppant following a fracture treatment.