Shell and Tube Heat Exchangers: A Classic Solution for Heat Transfer

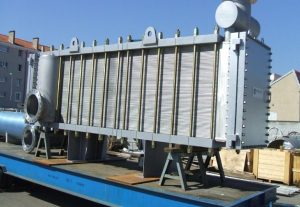

Shell and tube heat exchangers are one of the most common types of heat exchangers used in various industries, including oil and gas, chemical processing, power generation, and HVAC systems. They are versatile and reliable, capable of handling a wide range of fluids and temperature differences.

How Shell and Tube Heat Exchangers Work

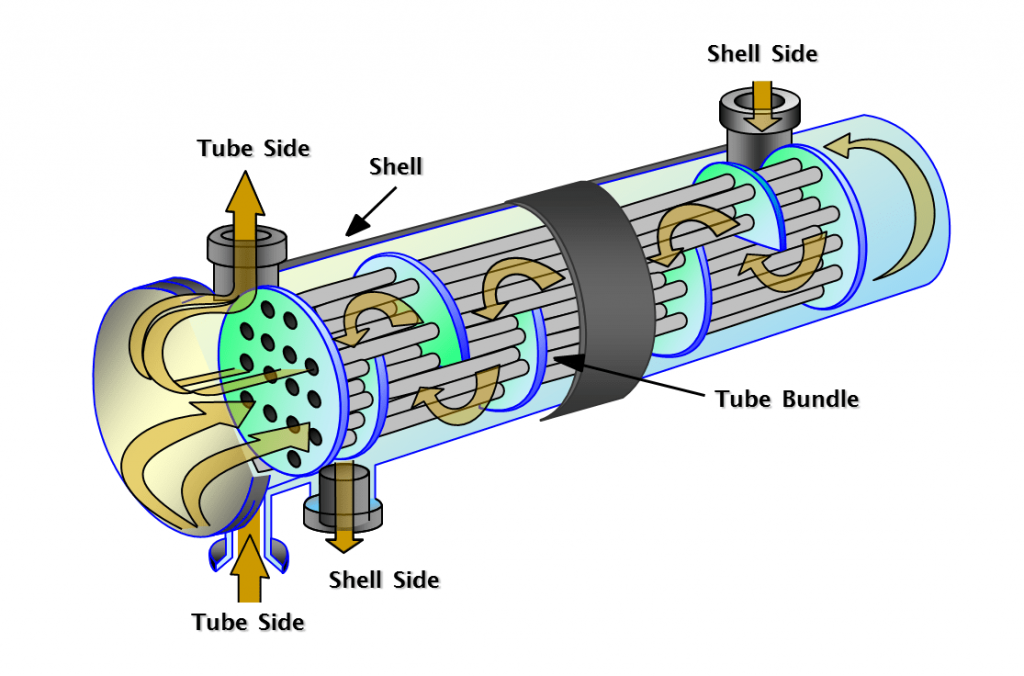

A shell and tube heat exchanger consists of a cylindrical shell that houses a bundle of tubes. One fluid flows through the tubes, while the other fluid flows through the shell. Heat is transferred between the two fluids through the tube walls.

Key Components of a Shell and Tube Heat Exchanger:

- Shell: The outer cylindrical casing that encloses the tube bundle.

- Tube Bundle: A bundle of tubes arranged in a specific pattern within the shell.

- Tube Sheets: The plates at the ends of the tube bundle that hold the tubes in place.

- Baffles: Plates or grids placed inside the shell to direct the flow of the shell-side fluid and improve heat transfer efficiency.

- Nozzles: Connections for the inlet and outlet of both fluids.

Pictured above: Basics of a Shell Tube Heat Exchangers

Thermal design

The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarised as follows:

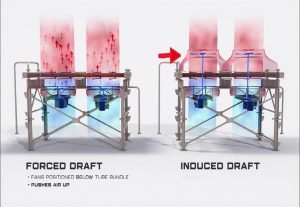

- Process fluid assignments to shell side or tube side.

- Selection of stream temperature specifications.

- Setting shell side and tube side pressure drop design limits.

- Selection of heat transfer models and fouling coefficients (shell and tube side).

- Selection of heat exchanger layout and number of passes.

- Specification of tube parameters – size, layout, pitch and material.

- Setting upper and lower design limits on tube length.

- Specification of shell side parameters – materials, baffle cut, baffle spacing, etc.

Types of Shell and Tube Heat Exchangers:

- U-Tube Heat Exchangers: The tubes are bent into a U-shape, allowing for thermal expansion and contraction.

- Fixed Tube Sheet Heat Exchangers: The tube sheets are fixed to the shell, making them suitable for high-pressure applications.

- Floating Head Heat Exchangers: One tube sheet is fixed, while the other is allowed to move to accommodate thermal expansion and contraction.

Advantages of Shell and Tube Heat Exchangers:

- Versatility: Can handle a wide range of fluids and temperature differences.

- Reliability: Proven technology with a long history of reliable operation.

- Flexibility: Can be designed for various flow rates and pressure ratings.

- Ease of Maintenance: Tubes can be replaced or cleaned individually.

Disadvantages of Shell and Tube Heat Exchangers:

- Complex Design: Can be complex to design and manufacture.

- Potential for Fouling: The tubes and shell can become fouled with deposits, reducing heat transfer efficiency.

- High Initial Cost: Can be more expensive than other types of heat exchangers.

Shell and tube heat exchangers continue to be a reliable and efficient solution for heat transfer in a wide range of industries.

By understanding the principles of operation and the key design considerations, engineers can select and design shell and tube heat exchangers that meet the specific needs of a particular application.