The Importance of Hydrostatic Testing in Pressure Vessel Certification

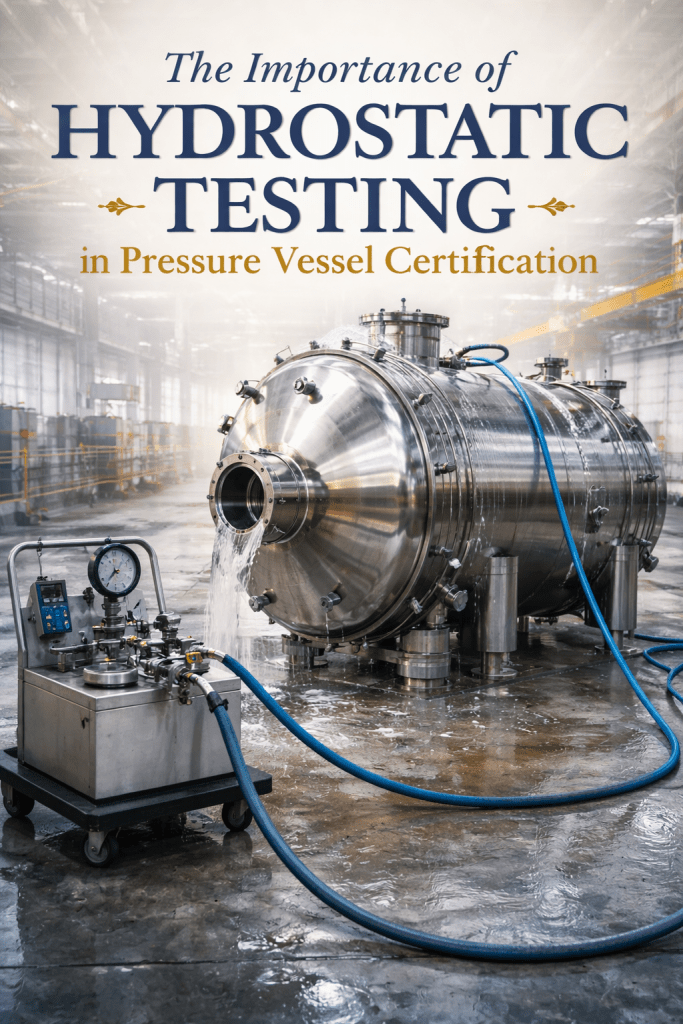

Before a pressure vessel ever goes into service, it must prove its integrity. One of the most critical steps in this process is hydrostatic testing—a time-tested method for ensuring that a vessel can safely handle its intended pressure load. More than just a regulatory checkbox, hydrotesting plays a vital role in preventing leaks, failures, and potential hazards in high-pressure systems.

In this post, we’ll explore what hydrostatic testing is, why it’s required, how it’s performed, and what engineers need to consider to stay compliant and confident in their vessel’s performance.

What Is Hydrostatic Testing?

Hydrostatic testing involves filling a pressure vessel with water (or another incompressible fluid) and pressurizing it to a specified level—typically 1.3 to 1.5 times the design pressure. The goal is to verify the structural integrity and leak tightness of the vessel under controlled conditions.

Because water is incompressible, the risk of energy release during failure is much lower than in pneumatic tests, making hydrotesting a safer option for most applications.

Why Is It Required?

Hydrotesting is a requirement of the ASME Boiler and Pressure Vessel Code (BPVC), particularly in Section VIII for unfired pressure vessels. It’s also a key part of many national and international pressure equipment directives.

The test serves several important purposes:

- Verifies Design and Fabrication Integrity

Ensures the vessel was built to specification and can handle the intended pressure without deformation or failure. - Detects Leaks

Surface flaws, pinholes, or faulty welds may not show up during manufacturing, but hydrotesting reveals these weaknesses under stress. - Ensures Safety Before Commissioning

Catching a defect before pressurized service prevents potentially catastrophic accidents during operation. - Meets Legal and Regulatory Requirements

Certification bodies often require documented hydrotests before a vessel can be legally operated.

How Is It Performed?

- Filling the Vessel

The vessel is filled with water, usually with added corrosion inhibitors. - Pressurization

Using a hydraulic pump, pressure is gradually increased to the test level, typically held for 10 minutes or more depending on code requirements. - Inspection

Engineers and inspectors monitor for visible leaks, permanent deformation, or pressure drop. - Documentation

Results are recorded for certification, with pass/fail criteria dictated by the applicable code or standard.

Key Considerations for Engineers

- Test Pressure Calculations

ASME Section VIII provides formulas to determine the proper test pressure based on material strength and design temperature. - Temperature Effects

Testing should be performed at ambient temperatures; colder conditions can increase brittleness and risk false failure. - Test Medium

Water is standard, but in special cases (e.g. vessels that cannot tolerate water), alternative fluids may be used—with additional safety precautions. - Post-Test Drying and Protection

Vessels must be thoroughly dried and sometimes treated after testing to prevent corrosion. - Retesting Requirements

In some cases—after repairs, rerating, or long periods of inactivity—hydrotesting may be required again before re-certification.

When Hydrotesting Might Not Be Used

While hydrotesting is standard, there are exceptions:

- Pneumatic Testing

Used when hydrotesting is impractical (e.g., vessel cannot get wet), but carries higher risk due to stored energy in compressible gases. Requires strict safety protocols. - Non-Destructive Examination (NDE)

In some modern applications, NDE methods like radiography or ultrasonic testing supplement or replace hydrotesting, though not always accepted for initial certification.

Conclusion

Hydrostatic testing is a cornerstone of pressure vessel certification. It provides tangible proof that a vessel is structurally sound and leak-free before it’s put into service. For engineers, it’s not just about meeting a code—it’s about delivering safe, reliable equipment that protects people, processes, and property.

Whether you’re designing new vessels or maintaining existing ones, understanding hydrotest procedures and requirements ensures you stay on the right side of compliance—and peace of mind.