The Role of Water Treatment in Boiler Efficiency and Longevity

A boiler is only as healthy as the water that feeds it. Without proper treatment, boiler feedwater can quietly degrade system performance, corrode metal surfaces, and drastically reduce equipment lifespan. In fact, poor water chemistry is one of the most common causes of boiler failure—yet it’s one of the most preventable.

In this post, we’ll explore why water treatment is critical, what problems it prevents, and how to build a treatment strategy that protects your boiler investment.

Why Water Treatment Matters

Even seemingly “clean” water contains minerals, gases, and impurities that can wreak havoc under high heat and pressure. Untreated or poorly treated water can lead to:

- Scale formation that reduces heat transfer efficiency

- Corrosion of internal components and piping

- Foaming and carryover that contaminate steam lines

- Sludge buildup that clogs tubes and lowers capacity

Proper water treatment is essential to maintain performance, comply with regulations, and avoid costly downtime.

Pictured above: A Boiler

Key Water Treatment Goals

- Prevent Scale

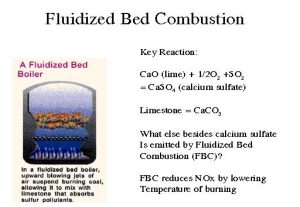

Minerals like calcium and magnesium precipitate under heat, forming hard, insulating scale on boiler surfaces. This leads to overheating, inefficiency, and tube failure. - Control Corrosion

Dissolved oxygen and carbon dioxide in feedwater create a corrosive environment. Corrosion weakens metal, shortens vessel life, and leads to leaks. - Remove Suspended Solids

Particulate matter can settle in low-flow areas, forming sludge that reduces heat transfer and flow. - Stabilize pH Levels

Water that’s too acidic or too alkaline accelerates metal degradation and affects chemical treatment effectiveness. - Prevent Carryover

Poor water chemistry can cause foaming and priming, resulting in moisture and impurities contaminating steam lines and processes.

Types of Boiler Water Treatment

Pretreatment (Before the Boiler)

- Softening: Removes hardness-causing minerals to prevent scale

- Filtration: Removes suspended solids

- Deaeration: Strips out dissolved gases like oxygen and CO₂

- Reverse Osmosis (RO): For high-purity systems (removes up to 99% of dissolved solids)

- Internal Treatment (Inside the Boiler)

- Oxygen scavengers (e.g., sodium sulfite) to reduce corrosion

- Scale inhibitors to prevent mineral buildup

- Phosphate treatments to condition hardness particles

- pH adjusters to maintain neutral to mildly alkaline conditions

- Blowdown

- Controlled removal of boiler water to maintain chemical balance and remove sludge or dissolved solids.

Monitoring and Testing

Regular water testing ensures treatment programs are working and alerts you to potential problems before damage occurs. Key tests include:

- Hardness

- Conductivity

- pH

- Dissolved oxygen

- Total dissolved solids (TDS)

Operators should test daily, weekly, or as advised by their water treatment partner. Automated monitoring systems can provide real-time alerts for faster response.

Partnering with a Water Treatment Expert

While some facilities manage treatment in-house, partnering with a certified water treatment provider offers benefits like:

- Custom chemical programs tailored to your water source and boiler

- On-site testing and troubleshooting

- Regulatory compliance guidance

- Long-term performance tracking

This collaborative approach ensures your system stays balanced and protected over time.

Conclusion

Water treatment may not be visible from the outside—but it’s the invisible backbone of boiler health. A well-maintained treatment program leads to longer equipment life, better fuel efficiency, fewer repairs, and safer operations.

Don’t wait for scale or corrosion to tell you something’s wrong. Get ahead of it with proactive, precise, and properly monitored water treatment.