U-Stamped Pressure Vessel

A U-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a pressure vessel has been manufactured and inspected in accordance with the rigorous standards outlined in the ASME® Boiler and Pressure Vessel Code (BPVC).

What is a Pressure Vessel?

A pressure vessel is a container designed to hold fluids or gases at pressures significantly higher than atmospheric pressure. They are used in various industries, including:

- Oil and Gas

- Chemical Processing

- Power Generation

- Pharmaceutical

- Food and Beverage

Pictured above: U-Stamped Pressure Vessels

Why U-Stamp Certification Matters:

- Safety: U-Stamp certification ensures that pressure vessels are designed, manufactured, and inspected to the highest safety standards.

- Reliability: U-Stamped vessels are built to last, minimizing the risk of failures and downtime.

- Compliance: U-Stamp certification demonstrates compliance with regulatory requirements, such as those set forth by the ASME® BPVC.

Key Design Considerations for U-Stamped Pressure Vessels:

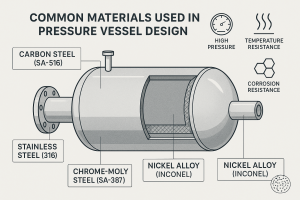

Material Selection:

- Materials must be selected based on their mechanical properties, corrosion resistance, and weldability.

- Common materials include carbon steel, low-alloy steel, and stainless steel.

Design Calculations:

- Stress analysis: To ensure that the vessel can withstand the internal pressure and external loads.

- Fatigue analysis: To assess the vessel’s ability to withstand cyclic loading.

- Thermal stress analysis: To account for thermal expansion and contraction.

Fabrication:

- Welding: Welding procedures must be qualified, and welders must be certified.

- Non-Destructive Examination (NDE): NDE techniques such as radiography, ultrasonic testing, and magnetic particle inspection are used to detect defects.

- Heat Treatment: Heat treatment may be required to improve the mechanical properties of the material.

Inspection and Testing:

- Hydrostatic testing: The vessel is filled with water and pressurized to verify its strength and integrity.

- Pneumatic testing: The vessel is pressurized with air or gas to check for leaks.

- Visual inspection: To check for surface defects, corrosion, and other issues.

By adhering to the stringent requirements of the ASME® BPVC, U-Stamped pressure vessels provide a high level of safety and reliability. When selecting a pressure vessel, it is important to choose a product that is U-Stamp certified to ensure compliance with industry standards and regulatory requirements.