UM-Stamped Pressure Vessels

A UM-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It authorizes a manufacturer to repair and alter existing pressure vessels and boilers. This certification ensures that repairs and alterations are performed in accordance with the ASME® Boiler and Pressure Vessel Code (BPVC).

Key Differences Between U-Stamp and UM-Stamp:

U-Stamp: Authorizes the manufacture of new pressure vessels and boilers.

UM-Stamp: Authorizes the repair and alteration of existing pressure vessels and boilers.

Pictured above: UM-STAMP-AIR-RECEIVER

Design Considerations for UM-Stamped Repairs and Alterations:

When repairing or altering a pressure vessel, the following design considerations must be taken into account:

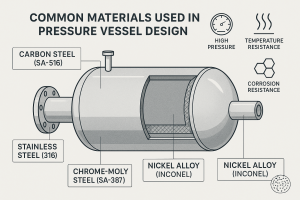

Material Selection:

- Repair materials must be compatible with the original material.

- The mechanical properties of the repair material must be sufficient to withstand the operating conditions.

Welding Procedures:

- Welding procedures must be qualified and performed by certified welders.

- Post-weld heat treatment may be required to relieve stresses and improve the mechanical properties of the weld.

Non-Destructive Examination (NDE):

- NDE techniques such as radiography, ultrasonic testing, and magnetic particle inspection must be used to verify the quality of the repair.

Hydrostatic Testing:

- The repaired or altered vessel may need to be hydrostatically tested to verify its integrity.

Documentation:

- Detailed records of the repair or alteration, including inspection reports and test results, must be maintained.

Key Challenges in UM-Stamped Repairs and Alterations:

- Access to Original Design Data: Obtaining accurate design data for older vessels can be challenging.

- Material Compatibility: Ensuring compatibility between repair materials and the original material.

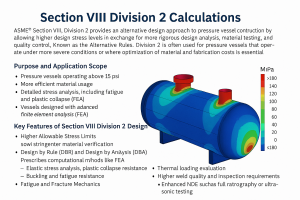

- Stress Analysis: Assessing the impact of the repair or alteration on the vessel’s stress distribution.

- Quality Control: Maintaining high quality standards throughout the repair process.

By adhering to the stringent requirements of the ASME® BPVC and the guidelines for UM-Stamp certification, manufacturers can ensure the safety and reliability of repaired and altered pressure vessels.