(Coalescing Separators)

What is a Coalescing Gas Separator?

Coalescing gas separators are designed specifically for the removal of mist, fog, and dust from gas streams. These contaminants usually exist with the bulk of the particles having diameters considerably less than 10 microns; therefore, standard separators or scrubbers are not capable of effectively removing these minute particles.

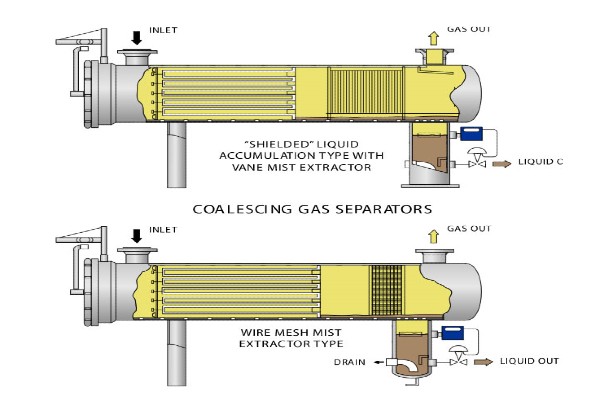

The coalescing gas separator consists of a vessel, combining specially constructed coalescing elements and a separation section with either a wire mesh or vane-type mist extractor. Like a separator, a liquid accumulation section is provided to properly collect and discharge the liquid for further processing or disposal.

Pictured above: a Coalescing Gas Separator.

How Does a Coalescer Work?

Coalescing takes place as the gas passes through the filter element in the sock-type replaceable filter elements. The fiberglass forces small particles to agglomerate (coalesce) -forming larger drops or particles. The resulting larger droplets are then removed from the gas as the stream flows through the separator section. Further removal of entrained droplets is provided by the wire mesh or vanes of the mist extractor. All separated droplets are then collected in the liquid accumulation section. Any dirt, dust, rust, and scale in the gas will be removed on the outside surface of the filter elements.

The typical application for coalescing gas separators is listed below:

- Ahead of glycol dehydrators remove compressor lube, oil, fog, salt water, dust, rust, and scale from the gas stream and prevent contamination of the glycol solution. (Croft Production Systems considers the installation of a coalescing separator a must ahead of a glycol dehydrator when gas is to be dried following compression.)

- Ahead of amine-treating units to prevent contamination of the amine solution by dust, rust, iron sulfide, scale, and liquid contaminants.

- Ahead of lean oil absorption plants to prevent contamination of the system by dust, rust, scale, and saltwater.

- Ahead of short cycle hydrocarbon recovery units to prevent “poisoning” of the desiccant.

- In the compressor fuel system to prevent plugging of the various orifices and valves.

- In refrigerant compressor discharge to recover the refrigeration compressor lube, oil, and to prevent contamination of the heat transfer surface in the process chiller or exchanger.

- Downstream of glycol absorbers or contractors to recover the entrained glycol mist carried overhead.

- Downstream of amine treating units to recover the amine solution and to prevent contamination of subsequent process equipment.

- Downstream of amine treating units to recover the amine solution and to prevent contamination of subsequent process equipment.

- Following lean oil absorbers to recover the lean oil (reducing operating costs), and to eliminate possible contamination of process equipment.

- Ahead of metering and regulating town border stations to assure long life and low maintenance of the turbine meter or standard orifice meter.

Coalescing Filter Features:

- Quick opening closure allows easy and rapid access to the filter assembly for cartridge replacement.

- All filter elements are readily accessible and can be changed quickly.

- Pressure taps are furnished to check the differential pressure drop across the coalescing elements. (Normally the pressure drop is approximately 0.5 psig with new cartridges. When the pressure drop reaches 5 to 7 psig, the cartridges should be replaced.)

- Choice of wire mesh mist extractor or vane-type mist extractor.

- ASME Code construction throughout.

- A wide range of sizes and capacities are available. Large sizes, providing high capacity, are available as horizontal units only.

- High-temperature filter elements are available for use with molecular sieves and short-cycle hydrocarbon recovery units.

- Models are available with a section ahead of the coalescing elements to accumulate and remove sizable quantities of free liquids.