What Authorized Inspectors Look for Before Applying the S-Stamp

If the ASME S-Stamp is the finish line, the Authorized Inspector (AI) is the gatekeeper holding the stopwatch.

Before that stamp ever touches a boiler, inspectors are verifying far more than weld quality or paperwork completeness. They’re answering one critical question:

Does this boiler fully comply with ASME Section I—by design, fabrication, documentation, and intent?

This article breaks down what Authorized Inspectors look for before applying the S-Stamp, why each item matters, and where projects most often stumble.

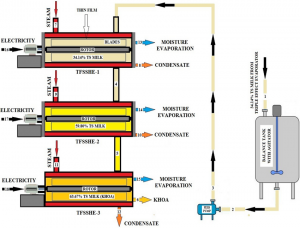

Pictured Above:

First: Understanding the Inspector’s Role

Authorized Inspectors don’t work for the manufacturer—and they don’t work against them either.

They represent:

- The jurisdiction

- The National Board

- Public safety

Their job is to independently verify compliance with ASME Section I (Power Boilers) and the manufacturer’s Quality Control (QC) Program.

No compliance, no stamp.

1. Valid ASME Authorization & Scope

Before fabrication even ramps up, inspectors confirm:

- A current ASME Certificate of Authorization

- Correct scope for Section I construction

- Valid Quality Control Manual approval

If authorization lapses—or the scope doesn’t match the work—the project stops immediately.

No exceptions. No grace period.

2. Quality Control Program Implementation

Inspectors don’t just review the QC Manual—they verify it’s being followed.

They look for:

- Documented procedures being used on the floor

- Personnel performing inspections as defined

- Objective evidence of compliance

A perfect manual means nothing if the shop isn’t living by it.

3. Material Traceability

Material control is one of the fastest ways to trigger inspection red flags.

Authorized Inspectors verify:

- Proper Material Test Reports (MTRs)

- Heat number traceability

- Correct material specifications per Section II

- Traceability maintained through fabrication

Lost heat numbers = lost confidence.

4. Welding Procedure & Welder Qualifications

This is where inspectors slow down.

They confirm:

- Approved Welding Procedure Specifications (WPS)

- Supporting Procedure Qualification Records (PQRs)

- Current welder performance qualifications

- Welders assigned within their qualified ranges

Even excellent welds can be rejected if the paperwork doesn’t support them.

5. Fit-Up, Joint Design, and Fabrication Practices

Before welding begins, inspectors review:

- Joint configurations

- Weld symbols and details

- Alignment and tolerances

- Compliance with Section I fabrication rules

Poor fit-up often leads to:

- Excessive repair welds

- Distortion

- Unnecessary inspection scrutiny

6. Required Nondestructive Examination (NDE)

Inspectors verify that:

- Required NDE is identified correctly

- Personnel are properly qualified

- Acceptance criteria match ASME Section I

- Results are documented and traceable

Skipping required NDE—or applying the wrong standard—is a common failure point.

7. Hydrostatic Pressure Testing

No S-Stamp without a successful hydro test.

Authorized Inspectors ensure:

- Test pressure meets Section I requirements

- Proper test duration

- Correct calibration of gauges

- Inspector presence and documentation

This test is non-negotiable.

8. Data Report Accuracy and Completeness

Before stamping, inspectors review the ASME Manufacturer’s Data Report line by line.

They confirm:

- All fields completed correctly

- Material and design data aligns with fabrication records

- No discrepancies between drawings and documentation

One incorrect entry can delay stamping.

9. Nameplate and Marking Requirements

Inspectors verify:

- Correct nameplate content

- Proper stamping location

- Accuracy of pressure, temperature, and capacity values

- Compliance with ASME and National Board requirements

The nameplate is the boiler’s permanent identity.

10. Overall Code Intent

Finally, inspectors step back and assess the big picture:

- Does the construction meet both the letter and intent of the Code?

- Were any shortcuts taken?

- Are there unresolved nonconformances?

If something doesn’t feel right—even if it’s technically compliant—expect questions.

Why Projects Fail at the Finish Line

Most S-Stamp delays aren’t due to bad workmanship.

They’re caused by:

- Incomplete documentation

- Late involvement of the Authorized Inspector

- Poor material control

- Misunderstanding Section I requirements

By the time these issues surface, fixes are expensive.

How to Set Yourself Up for a Smooth S-Stamp

Successful manufacturers:

- Engage the Authorized Inspector early

- Treat documentation as seriously as fabrication

- Maintain strict material traceability

- Verify qualifications before work begins

- Address nonconformances immediately

The S-Stamp should be the final confirmation—not the first time compliance is reviewed.

Final Thoughts

The S-Stamp isn’t just a mark—it’s a declaration.

It says the boiler was built correctly, documented properly, and inspected independently.

Understanding what Authorized Inspectors look for removes guesswork, reduces delays, and builds trust throughout the project.