ASME® B31.1: A Comprehensive Guide to Power Piping Design

The ASME® B31.1 Code for Power Piping is a widely recognized standard that provides guidelines for the design, fabrication, and installation of piping systems for power plants. This code ensures the safety and reliability of piping systems by establishing rigorous design and construction standards.

Key Design Considerations for B31.1 Piping Systems:

Material Selection:

- Carbon Steel: Commonly used for low-temperature and low-pressure applications.

- Alloy Steel: Used for high-temperature and high-pressure applications.

- Stainless Steel: Used for corrosive environments and high-temperature applications.

- Non-Ferrous Metals: Used for specific applications, such as copper alloys for condensate piping.

Design Stresses and Allowable Stresses:

- Stress Analysis: The design must ensure that the stresses in the piping system are within allowable limits.

- Allowable Stresses: The ASME® B31.1 Code provides allowable stresses for different materials and temperature ranges.

Piping Supports:

- Piping supports must be designed to adequately support the weight of the piping and the loads imposed by thermal expansion and contraction.

- Supports should be spaced to minimize stress and vibration.

Pipe Sizing:

- Pipe size is determined based on flow rate, pressure drop, and velocity considerations.

- The ASME® B31.1 Code provides guidelines for pipe sizing.

Valves and Fittings:

- Valves and fittings must be selected based on the pressure, temperature, and fluid service.

- The ASME® B16 series of standards provides specifications for valves, fittings, and flanges.

Welding and Inspection:

- Welding procedures must be qualified, and welders must be certified.

- Non-destructive examination (NDE) techniques, such as radiography, ultrasonic testing, and magnetic particle inspection, must be used to verify the quality of welds.

Insulation and Corrosion Control:

- Proper insulation can reduce heat loss and prevent condensation.

- Corrosion control measures, such as coatings and cathodic protection, may be required.

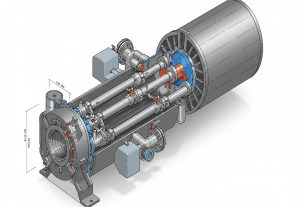

Pictured above: B31.1 Piping in Plant

By adhering to the ASME® B31.1 Code, engineers can design and construct safe and reliable piping systems. Regular inspection and maintenance are also crucial to ensure the long-term performance of the piping system.