Cold Heat Exchangers: A Critical Component in Refrigeration Systems

Cold heat exchangers, also known as condensers, are essential components in refrigeration and air conditioning systems. They transfer heat from a refrigerant to a cooling medium, typically air or water, to condense the refrigerant vapor into a liquid state.

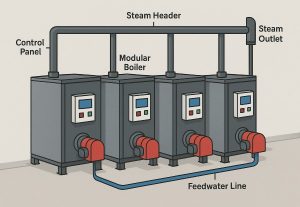

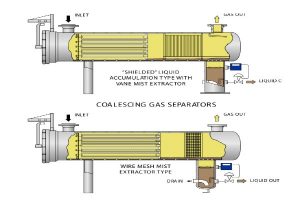

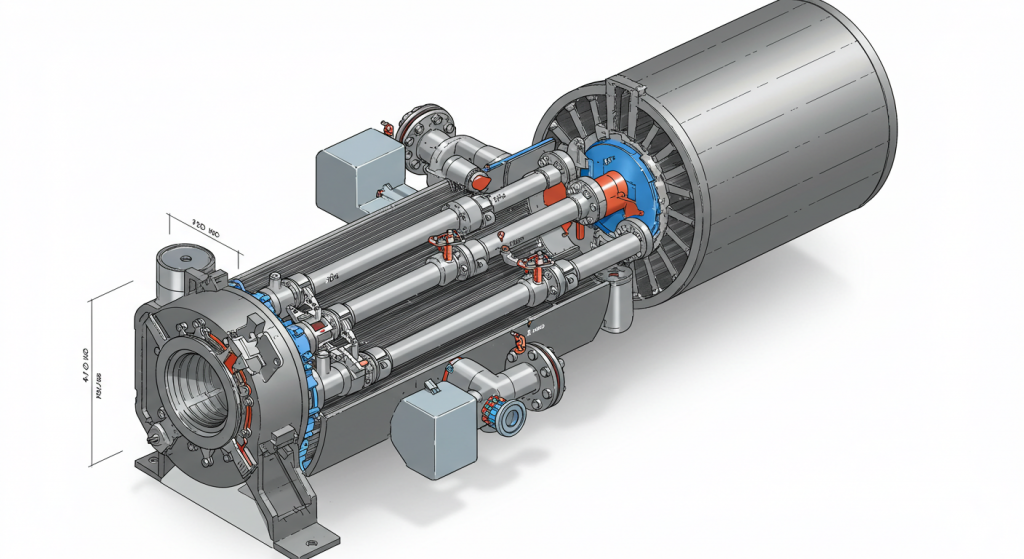

Pictured above: Cold Heat Exchangers

How Cold Heat Exchangers Work

A cold heat exchanger typically consists of a coil or tube through which the refrigerant flows. This coil is exposed to the cooling medium, which can be air or water. As the refrigerant vapor passes through the coil, it loses heat to the cooling medium and condenses into a liquid.

Types of Cold Heat Exchangers:

- Air-Cooled Condensers:

- Use air as the cooling medium.

- Can be fan-cooled or natural draft.

- Suitable for outdoor installations.

- Water-Cooled Condensers:

- Use water as the cooling medium.

- More efficient than air-cooled condensers, but require a water source.

- Common in large-scale refrigeration systems.

- Evaporative Condensers:

- Combine air and water cooling to achieve efficient heat rejection.

- Suitable for areas with high ambient temperatures.

Key Design Considerations for Cold Heat Exchangers:

- Heat Transfer Area: The surface area of the heat exchanger should be sufficient to transfer the required amount of heat.

- Refrigerant Flow Rate: The flow rate of the refrigerant should be optimized to ensure efficient heat transfer.

- Cooling Medium Flow Rate: The flow rate of the cooling medium should be sufficient to remove the heat from the refrigerant.

- Pressure Drop: The pressure drop across the heat exchanger should be minimized to reduce energy consumption.

- Material Selection: The materials used for the heat exchanger should be compatible with the refrigerant and cooling medium.

- Fouling and Corrosion: The design should consider fouling and corrosion mechanisms and incorporate measures to mitigate their effects.

Factors Affecting the Performance of Cold Heat Exchangers:

- Ambient Temperature: Higher ambient temperatures reduce the efficiency of air-cooled condensers.

- Water Temperature: Lower water temperature improves the efficiency of water-cooled condensers.

- Refrigerant Type: The properties of the refrigerant, such as its boiling point and latent heat of vaporization, affect the heat transfer rate.

- Fan or Pump Power: The power consumption of the fans or pumps used to circulate the cooling medium.

Cold heat exchangers play a critical role in maintaining the performance of refrigeration and air conditioning systems. By understanding the key design considerations and selecting the appropriate type of heat exchanger, engineers can ensure optimal performance and energy efficiency.