U-Stamp vs. UM-Stamp

In the realm of pressure vessel and boiler manufacturing, U-Stamp and UM-Stamp certifications signify adherence to rigorous quality standards. Both certifications are issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI), but they pertain to different aspects of manufacturing and inspection.

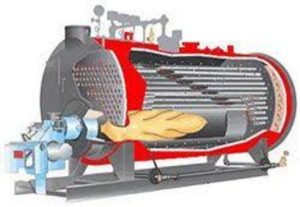

U-Stamp Certification

A U-Stamp certification indicates that a manufacturer is authorized to build and stamp pressure vessels and boilers. This certification ensures that the manufacturer adheres to the ASME Boiler and Pressure Vessel Code (BPVC), which outlines the design, fabrication, and inspection standards for these products.

Key Requirements for U-Stamp Certification:

- Quality Assurance Program: The manufacturer must have a comprehensive quality assurance program in place.

- Material Certification: All materials used in the construction of pressure vessels and boilers must be certified to meet specific standards.

- Welding Procedures and Qualifications: Welding procedures must be qualified, and welders must be certified to perform specific welding tasks.

- Non-Destructive Examination (NDE): NDE techniques, such as radiography, ultrasonic testing, and magnetic particle inspection, must be used to verify the quality of welds and other components.

- Hydrostatic Testing: Pressure vessels and boilers must undergo hydrostatic testing to verify their structural integrity.

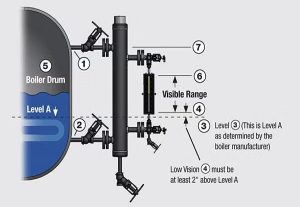

Pictured above: U-Stamp vs. UM-Stamp

UM-Stamp Certification

A UM-Stamp certification indicates that a manufacturer is authorized to repair and alter pressure vessels and boilers. This certification ensures that repairs and alterations are performed in accordance with the ASME BPVC.

Key Requirements for UM-Stamp Certification:

- Quality Assurance Program: The manufacturer must have a quality assurance program in place for repair and alteration activities.

- Welder Qualifications: Welders must be qualified to perform repairs and alterations.

- NDE: NDE techniques must be used to verify the quality of repairs and alterations.

- Hydrostatic Testing: Pressure vessels and boilers may require hydrostatic testing after repairs or alterations.

Key Differences Between U-Stamp and UM-Stamp:

Feature | U-Stamp | UM-Stamp |

Scope | Manufacturing of new pressure vessels and boilers | Repair and alteration of existing pressure vessels and boilers |

Certification Process | More rigorous, involving design, fabrication, and inspection | Focused on repair and alteration procedures |

Quality Assurance Requirements | Comprehensive quality assurance program | Specific quality assurance procedures for repairs and alterations |

Feature

Key Differences Between U-Stamp and UM-Stamp:

- 1. Scope

- 2. Certification Process

- 3. QA Requirements

U-Stamp

- 1. Manufacturing of new pressure vessels & boilers

- 2. More rigorous, involving design, fabrication, & inspection

- 3. Comprehensive quality assurance program

UM-Stamp

- 1. Repair & alteration of existing pressure vessels & boilers

- 2. Focused on repair & alteration procedures

- 3. Specific quality assurance procedures for repairs & alterations

In Conclusion:

Both U-Stamp and UM-Stamp certifications are essential for ensuring the safety and reliability of pressure vessels and boilers. By understanding the differences between these certifications, you can make informed decisions when selecting manufacturers and suppliers.

Feature

- 1. Scope

- 2. Certification Process

- 3. QA Requirements

U-Stamp

- 1. Manufacturing of new pressure vessels & boilers

- 2. More rigorous, involving design, fabrication, & inspection

- 3. Comprehensive quality assurance program

UM-Stamp

- 1. Repair & alteration of existing pressure vessels & boilers

- 2. Focused on repair & alteration procedures

- 3. Specific quality assurance procedures for repairs & alterations