Fluidized Bed Boilers: Efficient Combustion Meets Code Compliance

Understand how fluidized bed boilers work, their benefits, and what inspectors look for during code-compliant evaluations.

What Are Fluidized Bed Boilers?

Fluidized bed boilers (FBBs) use a unique combustion method where solid fuel particles are suspended in an upward flow of air — creating a fluid-like state. This allows for highly efficient combustion at lower temperatures with improved emissions control.

They’re widely used in biomass plants, waste-to-energy operations, and power stations that require flexible fuel use and strict emissions standards.

There are two main types:

- Bubbling Fluidized Bed (BFB)

- Circulating Fluidized Bed (CFB)

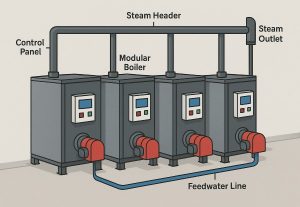

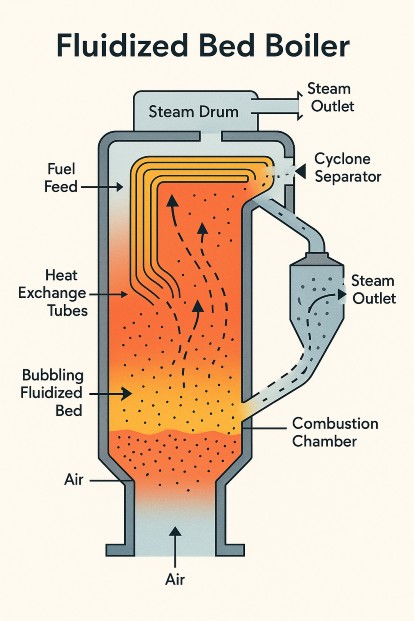

Pictured above: Fluidized Bed Boilers

How Do They Work?

In an FBB, crushed solid fuel (coal, biomass, waste) is introduced into a combustion chamber. A powerful stream of air from below fluidizes the fuel bed — suspending particles and improving heat transfer.

Key Components:

- Air distributor / plenum chamber

- Combustion chamber with refractory

- Fuel feed and ash removal system

- Heat exchange tubes

- Cyclone separator (in CFBs)

- Steam drum and waterwalls

The design allows operation at lower temperatures (~850°C), which helps reduce NOx and controls SO₂ through in-bed limestone injection.

Why Choose Fluidized Bed Boilers?

✅ Flexible fuel options — burn biomass, coal, waste, etc.

✅ Low NOx and SOx emissions — cleaner than traditional systems

✅ High combustion efficiency — even with low-grade fuels

✅ Better heat transfer — ideal for large-scale operations

✅ Lower furnace temps — reduces slagging and corrosion

They’re especially useful in industries with diverse or low-quality fuel streams — and where environmental regulations are tight.

Inspection Focus for Fluidized Bed Boilers

Fluidized bed boilers introduce additional mechanical, thermal, and chemical stresses on pressure parts and refractory — so thorough inspection is critical.

Authorized Inspector teams evaluate:

- Erosion in tubes and walls from circulating particles

- Refractory integrity in the bed and lower furnace

- Cyclone wear or cracking (CFB systems)

- Tube support alignment and expansion allowance

- Steam drum conditions and welds

- ASME Section I compliance for pressure parts

- NBIC tracking of repairs, rerates, or upgrades

We often coordinate with plant maintenance and refractory vendors to ensure inspection access and accuracy.

Code Compliance for Fluidized Bed Boilers

FBBs are subject to ASME Section I for pressure boundaries. Depending on the design, supporting components may invoke Section VIII, B31.1, or local jurisdictional rules.

Any modifications — especially to refractory-lined areas or steam-generating tubes — require NBIC-compliant documentation and R-Stamp authorization.

Where Fluidized Bed Boilers Shine

- Biomass and biofuel plants

- Municipal waste-to-energy facilities

- Utility-scale power plants

- Industrial operations with fuel flexibility

- Cement, paper, and food processing plants