Section VIII Division 1 Calculations

ASME® Section VIII, Division 1 provides the foundational framework for designing, constructing, and inspecting pressure vessels. These calculations are crucial for ensuring the safety, integrity, and compliance of vessels operating under pressure in a wide range of industrial environments, including oil and gas, chemical processing, power generation, and food production.

Purpose and Scope

Section VIII Division 1 specifically governs pressure vessels that:

- Operate at internal or external pressures greater than 15 psi

- Have a Maximum Allowable Working Pressure (MAWP) typically exceeding 300 psi

- Are subject to non-cyclic or moderate cyclic loading conditions

This division sets forth the rules for calculating essential design parameters based on established material properties, allowable stress limits, and various loading conditions.

Key Elements of Section VIII Division 1 Calculations

The methodology outlined in this section includes several critical components:

- Determination of Allowable Stresses

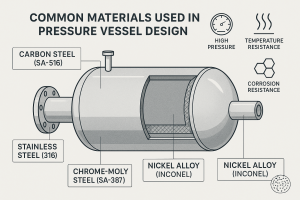

Allowable stresses are defined based on material specifications provided in the ASME Code. These stresses account for factors such as:

- Material strength at design temperatures

- Safety factors

- Weld efficiency

- Time-dependent properties (for high-temperature applications)

- Calculation of Component Thickness

Formulas are provided to determine the minimum required thickness for various vessel components, including:

- Shells and heads

- Nozzles and openings

- Flanges and tubesheets

These calculations incorporate design pressure, internal/external pressure loads, corrosion allowances, and manufacturing tolerances.

Weld Joint Efficiency and Inspection Considerations

The integrity of welded joints plays a critical role in pressure vessel performance. Section VIII mandates:

- Joint efficiency factors based on inspection methods (e.g., radiography, ultrasonic testing)

- Design adjustments based on weld type and inspection class

- Consideration for joint configurations (e.g., butt-welded, fillet-welded)

Analysis of Structural Stability

Stability calculations ensure the vessel can withstand:

- Buckling due to external pressure or vacuum conditions

- Thermal expansion and contraction

- External mechanical loads such as wind, seismic, and support loads

Engineering Application and Design Assurance

These calculations not only form the basis for vessel design but also:

- Provide traceable documentation for code compliance

- Support design verification by Professional Engineers (P.E.s)

- Facilitate quality assurance during fabrication and inspection

- Enable accurate certification and registration of the vessel

By rigorously following the guidelines in Section VIII Division 1, engineers can produce vessels that are not only code-compliant but also robust and safe under anticipated operating conditions.

Visit Our Partner J Lowry, LLC for Section VIII Division 1 Calculations