Section VIII Division 2 Design

ASME® Section VIII, Division 2 provides an alternative design approach to pressure vessel construction by allowing higher design stress levels in exchange for more rigorous design analysis, material testing, and quality control. Known as the Alternative Rules, Division 2 is often used for pressure vessels that operate under more severe conditions or where optimization of material and fabrication costs is essential.

Purpose and Application Scope

Division 2 is applicable to:

- Pressure vessels operating above 15 psi

- Situations requiring more efficient material usage

- Projects needing detailed stress analysis, including fatigue and plastic collapse

- Vessels designed with advanced finite element analysis (FEA)

This division is widely utilized in refineries, chemical plants, power generation, and other industries where weight reduction, advanced design scrutiny, and extended service life are key factors.

Key Features of Section VIII Division 2 Design

Division 2 differs from Division 1 in that it is analysis-intensive. The design process includes:

- Higher Allowable Stress Limits

By employing more stringent material verification and inspection procedures, Division 2 allows the use of higher allowable stresses, often leading to lighter and more cost-effective vessel designs.

- Design by Rule and Design by Analysis

- Design by Rule (DBR): Provides prescriptive formulas similar to Division 1, but with more refined calculations.

- Design by Analysis (DBA): Involves computational methods like FEA to assess vessel integrity, focusing on:

- Elastic stress analysis

- Plastic collapse protection

- Buckling and fatigue resistance

- Thermal loading evaluation

- Fatigue and Fracture Mechanics

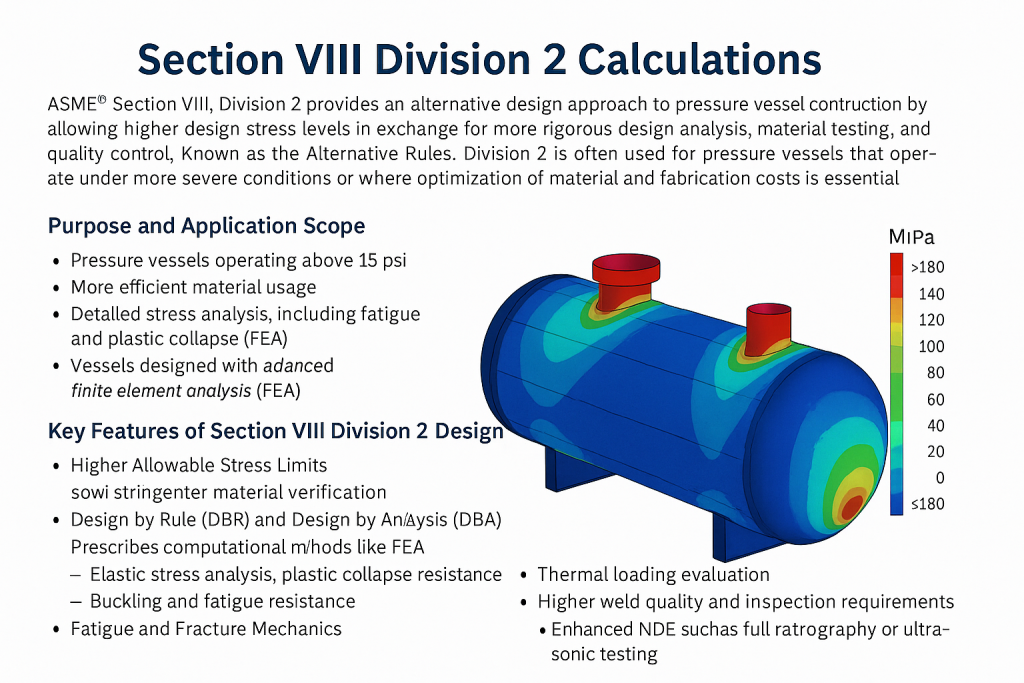

Pictured above: Section VIII, Division 2 Calculation information

Division 2 incorporates rigorous fatigue assessment and fracture analysis. This is critical for vessels exposed to:

- Cyclic pressure or temperature loads

- Severe service conditions

- Prolonged operational lifespans

Fatigue life assessment is based on cumulative damage calculations using detailed loading histories and stress ranges.

- Weld Quality and Inspection Requirements

Because the stress limits are higher, welding quality is held to stricter standards. Division 2 requires:

- Enhanced nondestructive examination (NDE) such as full radiography or ultrasonic testing

- Post-weld heat treatment under specific conditions

- Toughness testing for materials at certain thicknesses or low temperatures

- Material and Fabrication Requirements

Only materials listed in the ASME Code with clearly defined properties and toughness qualifications are allowed. Detailed fabrication records, Quality Assurance/Quality Control (QA/QC) protocols, and Inspector approvals are mandatory throughout the vessel lifecycle.

Why Use Section VIII Division 2?

Using Division 2 offers several benefits:

- Optimized material usage and reduced weight

- Lower fabrication costs over time, especially for large or complex vessels

- Improved fatigue life for dynamic or cycling environments

- Enhanced documentation and design confidence for regulators, clients, and insurers

Division 2 is the choice when performance, efficiency, and precision matter, and it provides a pathway for engineers to fully leverage modern computational tools like FEA in their pressure vessel designs.

At J Lowry, LLC, we offer:

- Full API 650 tank design packages

- Wind and seismic evaluations

- Anchor bolt and shell thickness calculations

- Floating roof design support

- P.E.-certified submittals and tank inspection support

Whether you’re building a new API 650 tank or modifying an existing one, our team ensures your tank is engineered to code, to spec, and to perform.