Mix Exchangers: Blending Efficiency and Energy Conservation

Mix Exchangers are a type of heat exchanger that combines two or more fluid streams to achieve a desired temperature or composition. They are widely used in various industries, including chemical processing, petroleum refining, and power generation.

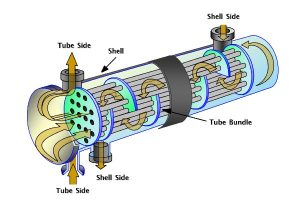

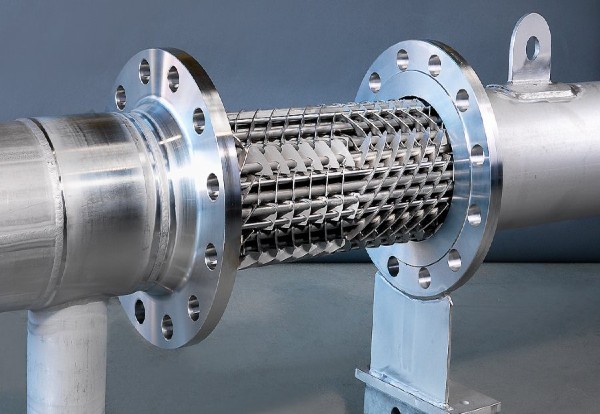

Pictured above: Mix Exchanger

How Mix Exchangers Work

- Static Mixers: These devices use a series of static elements to induce turbulence and promote mixing.

- Dynamic Mixers: These devices use rotating elements to create turbulence and enhance mixing.

Key Design Considerations for Mix Exchangers:

- Mixing Efficiency: The design should ensure thorough and rapid mixing of the fluids.

- Pressure Drop: The pressure drop across the mixer should be minimized to reduce pumping power requirements.

- Material Compatibility: The materials of construction should be compatible with the fluids being mixed.

- Corrosion Resistance: The materials should be resistant to corrosion from the fluids.

- Fouling Resistance: The design should minimize fouling and provide easy cleaning.

- Scale-up: The design should be scalable to accommodate different flow rates and fluid properties.

Design Data for Mix Exchangers

The design of a mix exchanger involves several key parameters:

- Flow Rate: The flow rates of the individual streams.

- Fluid Properties: The density, viscosity, and temperature of the fluids.

- Mixing Intensity: The degree of mixing required to achieve the desired outcome.

- Pressure Drop: The allowable pressure drop across the mixer.

- Material Compatibility: The compatibility of the fluids with the materials of construction.

Applications of Mix Exchangers:

- Temperature Control: Mixing hot and cold fluids to achieve a desired temperature.

- Blending: Mixing different components to create a specific blend.

- Dilution: Diluting concentrated solutions.

- Reaction Quenching: Rapidly cooling reaction products.

Mix exchangers play a critical role in many industrial processes. By understanding the key design considerations and selecting the appropriate type of mixer, engineers can optimize the performance of these devices.