S-Stamp Power Boilers

An S-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a manufacturer is authorized to build and stamp power boilers, which are pressure vessels designed to generate steam for various applications, such as power generation, heating, and industrial processes.

Pictured above: S Stamp Boiler

Key Requirements for S-Stamp Certification:

To obtain an S-Stamp, manufacturers must adhere to the rigorous standards outlined in the ASME® Boiler and Pressure Vessel Code (BPVC), Section I. This includes:

Design:

- Material Selection: The materials used in the construction of power boilers must meet the specific requirements of the ASME® BPVC.

- Stress Analysis: The design must be analyzed to ensure that the boiler can withstand the internal pressure and external loads.

- Thermal Stress Analysis: The design must account for thermal stresses that may arise from temperature differences.

Manufacturing:

- Welding: Welding procedures must be qualified, and welders must be certified.

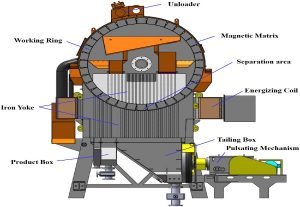

- Non-Destructive Examination (NDE): NDE techniques such as radiography, ultrasonic testing, and magnetic particle inspection must be used to verify the quality of welds and other components.

- Heat Treatment: Heat treatment may be required to improve the mechanical properties of the material.

- Fabrication: Fabrication processes must be carefully controlled to ensure the accuracy and quality of the components.

Inspection and Testing:

- Hydrostatic Test: The boiler must be hydrostatically tested to verify its structural integrity.

- Boiler Drum Inspection: The boiler drum must be inspected for corrosion, pitting, and other defects.

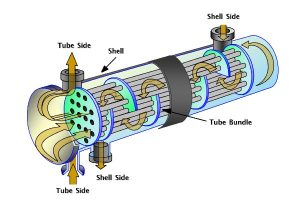

- Tube Inspection: Tubes must be inspected for pitting, corrosion, and other defects.

By meeting these rigorous standards, manufacturers of S-Stamped power boilers can ensure the safety and reliability of their products.

Key Design Data for S-Stamped Power Boilers:

- Boiler Pressure: The maximum allowable working pressure of the boiler.

- Boiler Capacity: The steam output capacity of the boiler.

- Material Specifications: The materials used for the boiler drum, tubes, headers, and other components.

- Design Codes and Standards: The specific codes and standards used for the design and fabrication of the boiler.

- Safety Relief Valves: The size, capacity, and set pressure of safety relief valves.

By understanding the design considerations and requirements for S-Stamped power boilers, engineers and manufacturers can design and build safe and reliable equipment.