Steam Heat Exchanger

Steam-heat exchangers are used to raise the temperature of well effluents to prevent hydrate formation, reduce viscosity, and break down emulsions for efficient separation of oil and water. Because steam-heat exchangers drastically reduce risk, they are used on offshore platforms and in other work conditions where safety regulations do not permit the use of indirect-fired heaters.

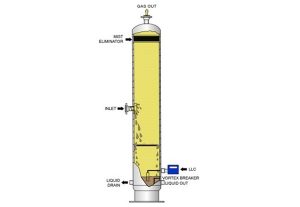

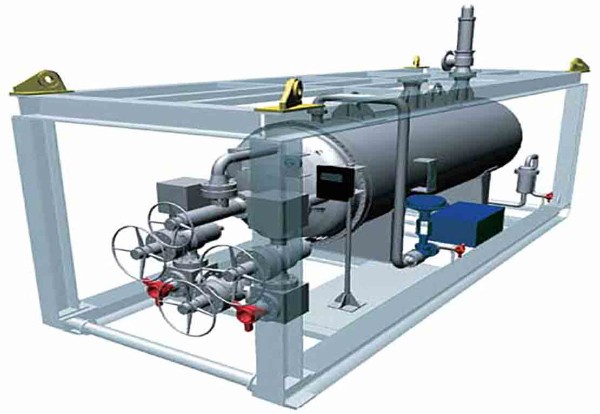

Pictured above: Steam Heat Echanger

How it improves operations

Steam-heat exchangers are used to raise the temperature of well effluents to prevent hydrate formation, reduce viscosity, and break down emulsions for efficient separation of oil and water. Because steam-heat exchangers drastically reduce risk, they are used on offshore platforms and in other work conditions where safety regulations do not permit the use of indirect-fired heaters.

Benefits of Steam Heat Exchanger include:

- Increases safety by eliminating fire risk

- Improves efficiency through hydrate formation prevention, viscosity reduction, and emulsion breakdown

This type of heat exchanger is also called a direct heating furnace which allows it to heat up the process coil directly. This is a kind of heating furnace that has the maximum heat exchange efficiency among the heating furnaces which are used in well testing. The superheated steam from the steam generator enters the pressure shell of the heating furnace to heat up the coil directly. Higher heat exchange efficiency and lower heat consumption are achieved on this equipment when compared with indirect heating furnaces. The coil is divided into upstream and downstream sections with an adjustable nozzle fitted between them to reduce the flow rate in the downstream coil section by throttling thus enabling more adequate heat exchange.

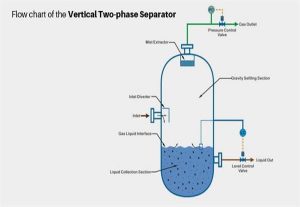

Pictured above: Steam-heat-exchanger-combo on skid mounts

Are they efficient?

Steam heat exchangers are very efficient, with thermal efficiencies of 98% to 100%. They extract virtually all the steam’s available energy. Steam heat exchangers are more efficient than other heat exchangers because they don’t rely on complex mechanical and air-chilling processes. Steam heating is fast and efficient. At the same temperature, steam transfers its heating energy much more efficiently than liquid water.

Heat is required for the following reasons:

- To reheat the process fluid after it cools due to pressure drop expansion across the choke.

- To prevent hydration.

- To reduce the surface tension and viscosity of the oil to aid in the separation of Emulsions, foaming crude, etc.

- To dissolve paraffin and asphaltenes to prevent deposits from forming on the interior components of the separation equipment.

- To reduce the viscosity of the oil to improve the following characteristics of high pour point crudes (The reduced viscosity will also improve the atomization of the oil at the burner, resulting in a cleaner burn.

How do they work?

The steam-heat exchanger is a steam vessel with two coils through which the well fluid passes. A choke assembly between the coils enables the well to be controlled at the steam exchanger instead of at the choke manifold. An inlet manifold with three gate valves controls fluid flow and provides a way to bypass the coils and choke. To maintain a preset temperature, the steam flowing into the vessel is regulated by an SCV on the steam inlet. A steam trap is mounted on the steam outlet line. The exchanger requires an adequate steam supply for operation. Some rigs have a sufficient steam supply, but usually, a steam generator is required.

The steam vessel is protected by a safety relief valve and a high-pressure pilot connected to the emergency shutdown system. The steam exchanger is insulated on the outside with glass wool and is covered with an aluminum jacket. All steam-heat exchanger models are skid-mounted units.