A Reliable Solution for Two-Phase Horizontal Separators

Two-Phase Horizontal Separators are a common type of pressure vessel used to separate gas and liquid mixtures. They are widely used in the oil and gas industry, as well as in other industries where gas-liquid separation is required.

How Two-Phase Horizontal Separators Work

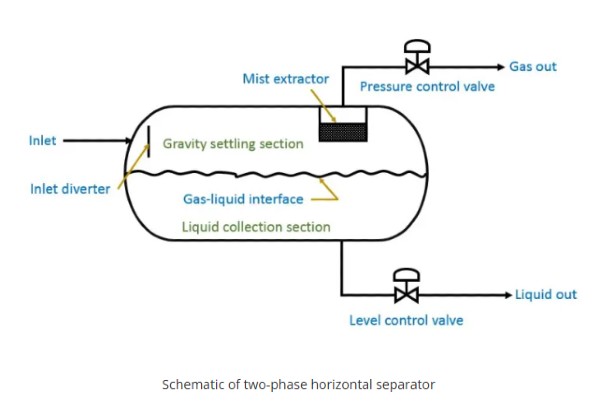

A horizontal separator is a cylindrical vessel that is oriented horizontally. When a gas-liquid mixture enters the separator, the heavier liquid phase settles to the bottom of the vessel, while the lighter gas phase rises to the top.

Pictured above: Schematic of two-phase horizontal separator

Key Components of a Horizontal Separator:

- Inlet Nozzle: The point where the gas-liquid mixture enters the separator.

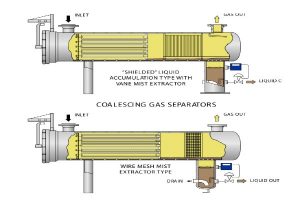

- Mist Eliminator: A device that removes liquid droplets from the gas stream.

- Gas Outlet Nozzle: The point where the separated gas exits the separator.

- Liquid Outlet Nozzle: The point where the separated liquid exits the separator.

Advantages of Horizontal Separators:

- Efficient Liquid-Liquid Separation: The horizontal design provides a larger liquid-liquid interface, promoting efficient separation of oil and water.

- Lower Pressure Drop: The longer horizontal path reduces pressure loss across the separator.

- Flexibility: Horizontal separators can be customized to accommodate various flow rates, pressures, and liquid-gas ratios.

Key Considerations for Separator Design and Selection:

- Capacity: The separator must be sized to handle the required flow rate.

- Pressure Rating: The separator must be designed to withstand the operating pressure.

- Material Selection: The materials of construction must be compatible with the fluid being processed.

- Mist Eliminator Selection: The mist eliminator must be selected based on the specific requirements of the application.

- Installation and Maintenance: Proper installation and regular maintenance are crucial for optimal performance.

Horizontal separators are a reliable and versatile solution for two-phase separation. Their efficient design and ease of maintenance make them a popular choice in many industries.