Efficiently Separating Gas and Liquid

A Two-Phase separator is a crucial piece of equipment in various industries, including oil and gas, chemical processing, and power generation. Its primary function is to separate a mixture of gas and liquid into its constituent phases.

The Two-Phase separators handle two-phase fluids. One is the gaseous phase and the other is the liquid phase. While a three-phase separator can separate out three phases; normally a gas, oil, and water (two liquid phases and one gas phase)

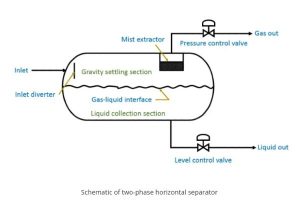

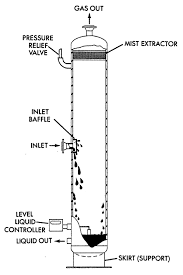

Pictured above: Two-phase separators

Two-phase vapor-liquid separators are used in many industries:

- Oil Refineries

- Chemical Plants

- Refrigeration Systems

- Natural Gas

- Petrochemical Processing Plants

Depending on the specific application and the vapor-liquid mixture being separated, two-phase vessels can be oriented vertically or horizontally. In their simplest form, they are an empty tank that are used to reduce the velocity of a fluid on entry, thus allowing the liquid to fall to the bottom of the vessel and the vapor to rise to the top. Most separators include internal devices that assist in the separation process, such as:

- An inlet diverter – An inlet diverter includes a downcomer that directs the inlet flow below the liquid level in the tank. This has the effect of stabilizing the liquid level while preventing splattering and foaming.

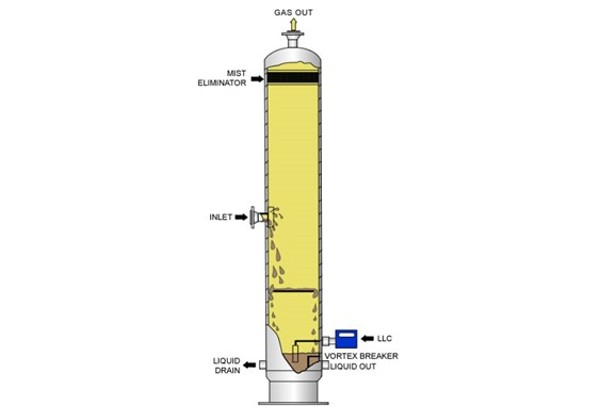

- A mist eliminator – A mist eliminator removes liquid droplets entrained with the gas.

Pictured above: Illustration of a Mist Extractor inside a vessel

How Two-Phase Separators Work

The basic principle behind a two-phase separator is the difference in density between gas and liquid. When a mixture of gas and liquid enters the separator, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top.

Key Components of a Two-Phase Separator

Inlet Nozzle: The point where the gas-liquid mixture enters the separator.

Mist Eliminator: A device that removes liquid droplets from the gas stream.

Gas Outlet Nozzle: The point where the separated gas exits the separator.

Liquid Outlet Nozzle: The point where the separated liquid exits the separator.

Types of Two-Phase Separators

- Advantages: Efficient liquid-liquid separation, lower pressure drop.

- Disadvantages: Larger footprint, more complex piping.

- Advantages: Smaller footprint, simpler design.

- Disadvantages: Lower liquid-liquid separation efficiency, higher pressure drop.

- Advantages: High capacity, low pressure drop, and reduced weight.

- Disadvantages: More complex design and higher cost.

Different Models and with different Performances

Since the stream conditions and required efficiency may vary widely, the Two-phase separator can be designed in many models and with different performances.

Gas-Liquid Separators

Two-phase separator is often used as a buffer/surge/accumulator tank/vessel. Different names show different parts of processed stream behavior and the application emphasis. Sometimes the key structure or component may also be indicated on separator names, such as vane pack separator and coalesce separator.

Liquid-Liquid Separators

As their name indicates, liquid-liquid separators are used to separate two immiscible liquids, like oil and water. The viscosity, specific gravity, and interfacial tension of the two liquids must be considered when designing this separator.

If the difference in density between the two liquids is large, separation can be achieved through gravity separation. In such instances, the heavier liquid is drawn off the bottom of the tank and the lighter liquid off the top. Otherwise, a coalescer can be used to facilitate liquid-liquid separation using plastic, polymer, wool, or fiberglass as a coalescing medium.

Solid-Liquid Separators

Solid-liquid separation is normally achieved through filtration, settling, or centrifugation. These types of separators utilize filters, which contain a porous medium that retains suspended solids as the mixture passes through it. Settlers are normally tanks of the very basic design that facilitate the settling of solids to the bottom of the vessel by gravity.

Factors Affecting Separator Performance

Inlet Velocity: High inlet velocities can lead to increased turbulence and reduced separation efficiency.

Liquid Load: The amount of liquid in the gas stream.

Gas Density: The density of the gas can affect the separation process.

Liquid Viscosity: The viscosity of the liquid can influence the settling rate of droplets.

Mist Eliminator Efficiency: The efficiency of the mist eliminator in removing liquid droplets from the gas stream.

Key Considerations for Separator Design and Selection:

Capacity: The separator must be sized to handle the required flow rate.

Pressure Rating: The separator must be designed to withstand the operating pressure.

Material Selection: The materials of construction must be compatible with the fluid being processed.

Mist Eliminator Selection: The mist eliminator must be selected based on the specific requirements of the application.

Installation and Maintenance: Proper installation and regular maintenance are crucial for optimal performance.

By understanding the principles of two-phase separation and the factors that influence separator performance, engineers can ensure the efficient and reliable operation of these critical components in various industrial processes.