Two-Phase Spherical Separators are a type of pressure vessel designed to separate gas and liquid mixtures into their individual components. They are particularly well-suited for applications where space is limited or where high flow rates and low pressure drop are required.

How Two-Phase Spherical Separators Work

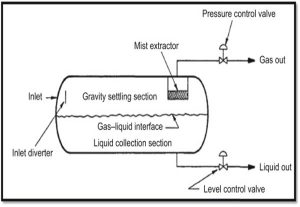

Spherical separators operate on the principle of gravity separation. When a gas-liquid mixture enters the vessel, the heavier liquid phase settles to the bottom, while the lighter gas phase rises to the top. The unique spherical shape of the vessel promotes efficient separation by minimizing turbulence and maximizing the contact area between the two phases.

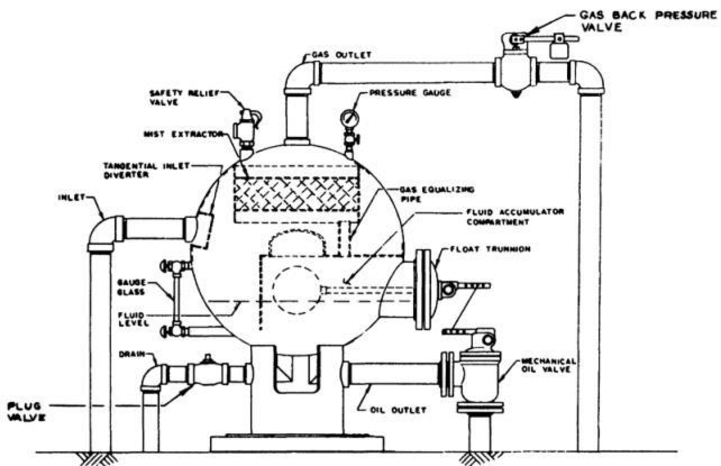

Pictured above: Spherical Separators-Low-Pressure Mechanical Controls

Key Advantages of Spherical Separators:

- Compact Design: Spherical separators require less floor space compared to traditional vertical or horizontal separators.

- High Capacity: The spherical shape allows for a larger internal volume, enabling the handling of higher flow rates.

- Low Pressure Drop: The smooth interior surface of the vessel minimizes pressure losses, resulting in improved energy efficiency.

- Reduced Maintenance: The simple design and fewer internal components reduce maintenance requirements.

- Versatility: Spherical separators can be used in a wide range of applications, including oil and gas production, chemical processing, and power generation.

Key Components of a Spherical Separator:

- Inlet Nozzle: The point where the gas-liquid mixture enters the separator.

- Mist Eliminator: A device that removes liquid droplets from the gas stream.

- Gas Outlet Nozzle: The point where the separated gas exits the separator.

- Liquid Outlet Nozzle: The point where the separated liquid exits the separator.

Selecting the Right Spherical Separator

When selecting a spherical separator, several factors must be considered:

- Capacity: The separator must be sized to handle the required flow rate.

- Pressure Rating: The separator must be designed to withstand the operating pressure.

- Material Selection: The materials of construction must be compatible with the fluid being processed.

- Mist Eliminator Selection: The mist eliminator must be selected based on the specific requirements of the application.

- Installation and Maintenance: Proper installation and regular maintenance are crucial for optimal performance.

Spherical separators offer a compact and efficient solution for two-phase separation. Their unique design and advantages make them a valuable asset in many industries.