Material Selection: A Critical Aspect of U-Stamp Certification

The selection of materials is a crucial step in the design and fabrication of pressure vessels and boilers. The ASME® Boiler and Pressure Vessel Code (BPVC) provides guidelines for material selection, ensuring the integrity and safety of these structures.

Key Considerations for Material Selection:

- Chemical Composition:

- The chemical composition of the material must meet the specific requirements of the ASME® BPVC.

- Elements such as carbon, manganese, sulfur, phosphorus, and silicon can significantly influence the mechanical properties of the material.

- Mechanical Properties:

- Yield Strength: The minimum stress at which a material begins to plastically deform.

- Tensile Strength: The maximum stress a material can withstand before breaking.

- Ductility: The ability of a material to deform plastically without fracturing.

- Toughness: The ability of a material to resist fracture.

- Impact Strength: The ability of a material to resist brittle fracture at low temperatures.

- Corrosion Resistance:

- The material must be resistant to corrosion from the fluids it will be exposed to.

- Corrosion-resistant alloys, such as stainless steel, may be required for specific applications.

- Weldability:

- The material must be weldable using appropriate welding techniques.

- Weldability is influenced by factors such as carbon content and alloying elements.

- Fatigue Strength:

- For components subjected to cyclic loading, fatigue strength is a critical consideration.

- The material must be able to withstand repeated stress cycles without failing.

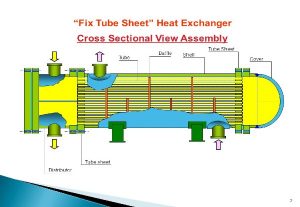

Pictured above: Pressure Vessel Head

Material Certification:

- Mill Test Reports (MTRs): MTRs provide information about the chemical composition and mechanical properties of the material.

- Material Test Reports (MTRs): MTRs document the results of tests performed on specific batches of material.

Code-Compliant Materials:

The ASME® BPVC specifies a range of materials that are suitable for use in pressure vessels and boilers. These materials are often listed in the ASME® Boiler and Pressure Vessel Code, Section II, Part A, and other relevant standards.

By carefully selecting and testing materials, manufacturers can ensure the safety and reliability of pressure vessels and boilers. Adherence to the ASME® BPVC and other relevant standards is essential to obtain and maintain U-Stamp certification.