Understanding the PP-Stamp

The PP-Stamp is a certification mark issued by the National Board of Boiler and Pressure Vessel Inspectors (NBBPVI). It signifies that a manufacturer is authorized to weld, fit, manufacture, and install piping and components that attach to external piping used for power boilers and pressure vessels.

What Does the PP-Stamp Certify?

- Adherence to Standards: Manufacturers with a PP-Stamp adhere to the ASME® Boiler and Pressure Vessel Code, Section B31.1, which outlines the design, fabrication, and installation standards for piping systems.

- Quality Assurance: The PP-Stamp indicates that the manufacturer has a robust quality assurance program in place.

- Material Compliance: The materials used in the fabrication of piping components must meet the specific requirements of the ASME® B31.1 Code.

- Welding Procedures: Welding procedures must be qualified, and welders must be certified.

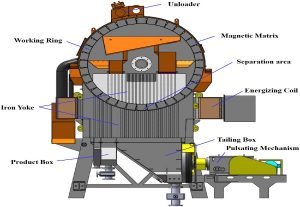

- Non-Destructive Examination (NDE): NDE techniques such as radiography, ultrasonic testing, and magnetic particle inspection must be used to verify the quality of welds and other components.

- Hydrostatic Testing: Piping components may be subjected to hydrostatic testing to verify their integrity.

Pictured above: PP Piping, B31.1 Code

Why is a PP-Stamp Important?

- Safety: The PP-Stamp ensures that piping components are manufactured and installed to the highest safety standards.

- Reliability: PP-Stamped components are designed to withstand the demanding conditions of power plants and other industrial facilities.

- Compliance: The PP-Stamp demonstrates compliance with regulatory requirements and industry best practices.

By selecting piping components with a PP-Stamp, you can ensure the reliability and safety of your pressure vessel and boiler systems.

Key Design Considerations for PP-Stamped Components:

- Material Selection: The material should be selected based on its mechanical properties, corrosion resistance, and weldability.

- Pipe Size and Wall Thickness: The pipe size and wall thickness must be sufficient to withstand the operating pressure and temperature.

- Welding Procedures: Welding procedures must be qualified, and welders must be certified.

- Non-Destructive Examination (NDE): NDE techniques must be used to verify the quality of welds and other components.

- Stress Analysis: The design must be analyzed to ensure that the stresses in the piping system are within allowable limits.

By adhering to the stringent requirements of the ASME® B31.1 Code, manufacturers of PP-Stamped components can ensure the safety and reliability of piping systems.