Understanding the Basics

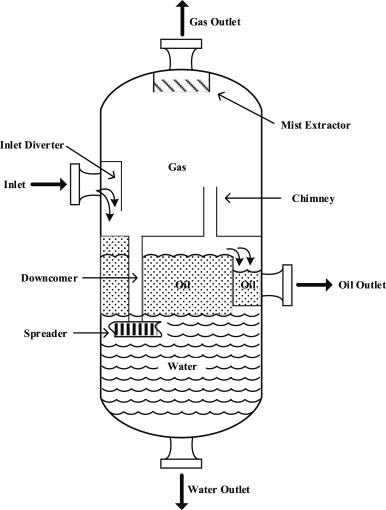

Vertical Three-Phase Separator with A Downcomer and Spreader

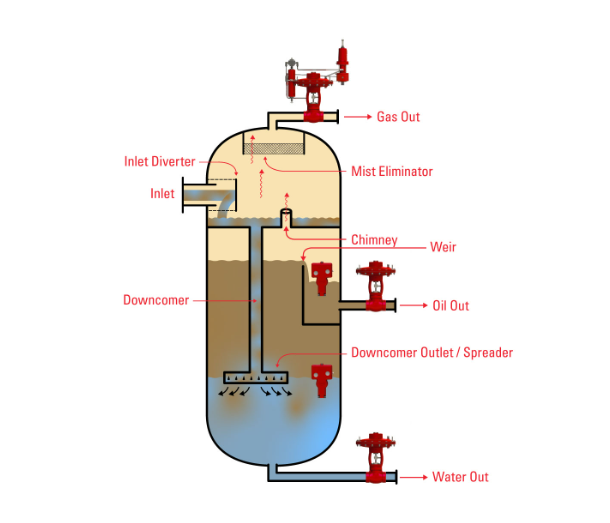

A three-phase separator is a crucial piece of equipment in the oil and gas industry, designed to separate a mixture of oil, gas, and water into its individual components. The vertical three-phase separator, equipped with a downcomer and spreader, is a particularly efficient design for handling a wide range of flow rates and liquid-gas ratios.

Pictured above: Vertical Three-Phase Separators with Downcomer and Spreader

The Role of the Downcomer and Spreader

- Downcomer: A downcomer is a pipe or channel that directs the liquid phase from the top of the separator to the bottom. It helps to prevent liquid droplets from being carried over into the gas outlet.

- Spreader: A spreader is a device that distributes the incoming fluid evenly across the cross-sectional area of the separator. This ensures efficient separation by providing adequate residence time for the different phases to separate.

How Does it Work?

- Inlet: The mixture of oil, gas, and water enters the separator through the inlet nozzle.

- Separation: As the mixture enters the vessel, the heavier liquids (oil and water) settle to the bottom, while the lighter gas rises to the top.

- Gas-Liquid Separation: The gas-liquid mixture is separated in the upper section of the separator. The gas rises to the top and exits through the gas outlet.

- Liquid-Liquid Separation: The liquid phase, consisting of oil and water, flows down the downcomer and enters the lower section of the separator.

- Liquid-Liquid Separation: In the lower section, the oil and water separate based on their specific gravities. The lighter oil layer is drawn off through the oil outlet, while the heavier water is removed through the water outlet.

Pictured above: Vertical 3-Phase Separator with A Downcomer and Spreader

Advantages of Vertical Three-Phase Separators with Downcomer and Spreader

- Efficient Separation: The combination of the downcomer and spreader ensures efficient separation of oil, gas, and water.

- Reduced Liquid Carryover: The downcomer helps to prevent liquid droplets from being carried over into the gas outlet, improving gas quality.

- Compact Design: Vertical separators require less floor space compared to horizontal separators.

- Flexibility: Can be customized to accommodate various flow rates, pressures, and liquid-gas ratios.

Key Considerations for Design and Operation

- Separator Size: The separator must be adequately sized to handle the expected flow rates and liquid-gas ratios.

- Downcomer and Spreader Design: The downcomer and spreader should be designed to ensure efficient liquid-liquid separation and minimize pressure drop.

- Inlet and Outlet Nozzles: The inlet and outlet nozzles should be properly sized and positioned to minimize turbulence and maximize separation efficiency.

- Internal Components: The internal components, such as baffles and mist eliminators, should be designed to optimize separation and minimize pressure drop.

- Maintenance: Regular maintenance is essential to ensure optimal performance and prevent equipment failures.

By understanding the principles of operation and the key design considerations, engineers can select and design vertical three-phase separators with downcomers and spreaders to meet the specific needs of oil and gas production facilities.